By Greg Austin

There are many obvious reasons why durability is important for commercial construction and the waterproofing of covered podiums and plaza decks, green roofs, balconies, and terraces. Most of these public areas need to withstand foot traffic, vehicles, and equipment transport. In all cases, especially with roofs, specifiers need to ensure there is a reliable, highly durable membrane sealing the surface and any design features to provide long-term water protection.

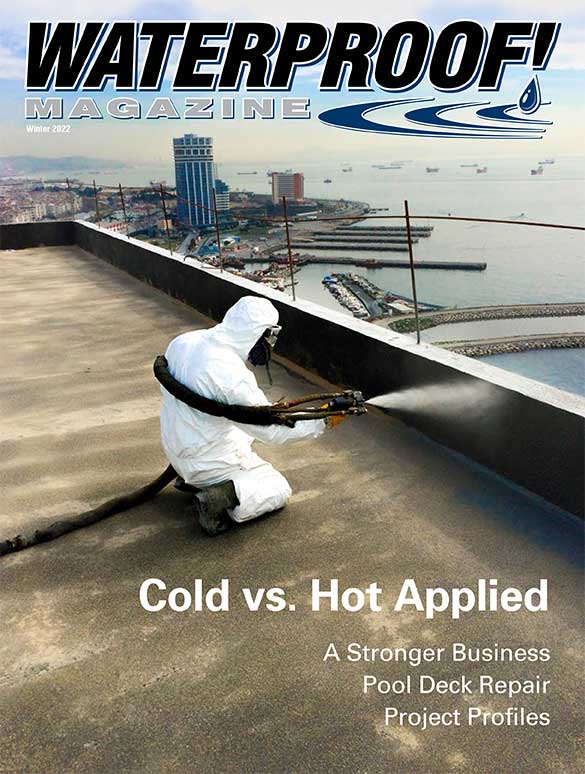

Commercial builders, designers, and architects can choose from numerous different types of waterproofing products. Liquid-applied is typically preferred when conformation to the given site layout and/or speed of installation are critical. There are two types of liquid waterproofing — cold-applied and hot-applied — each of them has its own set of features and benefits. In addition, the total amount of material needed to provide a reliable waterproofing layer should be considered. So, which type of liquid waterproofing is more durable? After looking at the durability factors in waterproofing, we will explore the differences between cold and hot-applied waterproofing, concluding which liquid waterproofing type is recommended based on those all-important durability factors.

Liquid Waterproofing and Durability

There are six major criteria that should be considered when assessing the durability performance of a component product and system overall, five of which are defined through ASTM International standard testing methods. The six testing criteria for vulcanized rubber and thermoplastic elastomers (the materials that hot-applied and cold-applied liquid waterproofing solutions are made of respectively) are as follows:

- Tensile (tension) strength (ASTM D412) – The ability to withstand tensile forces. Tensile strength measures the stress required to stretch the material to the point where it breaks. It can be used to evaluate the maximum amount of tensile force that a material can be subject to before failure.

- Tear resistance or tear strength (ASTM D624) – The resistance to tearing action, including the force to initiate tearing of the materials or tear propagation. With a waterproofing application, the force to initiate the tearing is particularly important.

- Adhesion to concrete (ASTM D4541/ASTM D7234) – The greatest perpendicular force a surface area can bear before a section of material is “pulled off” or detached. How well the material adheres to the concrete and maintains after water immersion is very critical with liquid waterproofing.

- Shore hardness (ASTM D2240) – The resistance a material has to indentation. This measures the indentation hardness of substances such as thermoplastic elastomers, vulcanized (thermoset) rubber, elastomeric materials, and some plastics.

- Abrasion resistance (ASTM D4060 – Taber Wear Index) – The rate of wear as calculated by measuring the loss in weight (in milligrams) per thousand cycles of abrasion. The lower the wear index, the better the abrasion resistance.

- Low-temperature crack bridging (ASTM C836 or ASTM C1305) – The ability of the material to maintain its integrity while bridging a crack in the substrate at low ambient temperatures when the polymeric materials are least likely to be flexible. Meeting this criterion allows the material to perform exceptionally at crack-bridging, a critical factor with construction-based waterproofing.

A waterproofing system should be evaluated on the basis of the results of this set of tests and should not be selected based on a single performance value. Importantly, the highest possible test value does not always translate into installed performance. Therefore the system should be evaluated in total to determine the likelihood of achieving the desired installed performance.

Product Materials and Chemistry

Hot-applied liquid waterproofing systems consist of rubberized asphalt. Multiple layers must be applied to achieve durability, along with a reinforcement layer made of fleece and a protection board, which add complexity to the installation. Because of the additional skill set required for the installation of reinforcement and protection, there is a greater chance of errors occurring during the installation that could affect the watertight performance and durability of the product.

Cold-applied liquid waterproofing requires applying only one or two layers (after the primer) to achieve durable performance. Some of these systems do not require a reinforcement layer or protection course during construction.

Damage Resistance

Asphalt-type hot-applied liquid waterproofing is composed of large proportions of low and medium molecular weight components and consequently does not stand up well to equipment grease and solvents that may be dropped on the surface. Also, it can handle only limited loads or cycles of abrasion on its surface before showing wear or penetration.

Most cold-applied liquid water-proofing systems are reactive and made to form a high molecular weight or cross-linking polymer. This results in good resistance to wear and tear, the hydrocarbons, grease, or solvents that are often spilled on the jobsite. A properly selected cold-applied liquid system can handle construction or ongoing activity, including mishaps, such as equipment and tools dropping on the surface. In a worst case scenario, an impact may break the concrete deck underneath the membrane and the waterproofing must have crack bridging capability to maintain its integrity.

Reactive cold-applied liquid water-proofing is often designed with the ability to handle “point loads,” which can be caused by a heavy piece of equipment with a narrow leg at the bottom or similar point load situations. Even in those instances, the membrane will not show a dent or penetration. One cold-applied waterproofing membrane, Silcor liquid waterproofing by GCP Applied Technologies, has demonstrated the ability to withstand point load of 3,000 psi without causing a dent on the membrane.

Overall, cold-applied waterproofing can handle greater loads and a higher number of cycles of abrasion than hot-applied.

Low Temperature Crack-bridging

Crack-bridging is a critical feature of liquid waterproofing materials due to the natural dynamic movement of buildings and structures that understandably creates cracks. In climates with temperature changes from season to season, these cracks can shift, open, and close. This back and forth movement of cracks as temperatures change creates many fatigue cycles for the waterproofing membrane.

Waterproofing materials need to withstand these various temperatures, and low temperatures in particular, so that when there is a crack in the substrate (typically concrete), the waterproofing membrane stays in its original condition. There will be no fine-line cracks or breaks in the membrane and it will remain monolithic, protecting the structure underneath by preventing water from getting through and damaging the structure.

Materials can become rigid, and some even brittle, when the temperature drops, rendering them unable to maintain their original condition under stress or repetitive movement. That is why, when choosing a waterproofing system, the material’s temperature related properties and overall chemistry should be given serious consideration.

Hot-applied liquid waterproofing requires continuous maintenance to ensure the membrane’s protection of the surface below. With respect to durability, enduring fatigue cycles of building movement or maintaining integrity over time, especially in cold temperatures, is a challenge for hot-applied liquid waterproofing.

The elastomeric qualities inherent in cold-applied liquid waterproofing membranes mean that they easily withstand building movements and fatigue cycles, maintaining their integrity over a long period of time and requiring no ongoing maintenance. Cold-applied liquid waterproofing can also handle more extreme temperatures, down to -15°F.

Application Durability

When applying hot rubberized asphalt at high temperatures, air will try to escape and moisture will try to evaporate through any defects in the primer, which can cause a good deal of blistering or pinholes.

Applying cold liquid greatly reduces the chance of evaporation of moisture and water trapped in concrete as well as expansion of trapped air in the concrete when compared to hot liquid application. With cold-applied waterproofing, you can build a continuous membrane for waterproofing integrity.

Safety Concerns

Safety concerns and issues are always looming large on construction sites due to the constantly changing and sometimes precarious surroundings, the handling of large and sometimes unstable equipment, and the use of chemicals and materials that may pose health, site, and environmental risks. Clearly, ensuring safety on a construction site is top of mind for site/building owners, architects, contractors and work crews. Safety needs to be a major consideration when deciding on which vendors and products to use for each project and phase on a construction site.

Waterproofing of roofs, podium and plaza decks, and other new or existing elevated structural decks can be accomplished with either a cold-applied or hot-applied liquid waterproofing product, each of which has its advantages for safety.

Hot Rubberized Asphalt (HRA)

The elements that create significant safety concerns with any project — the use of heat, open flame, and anything flammable — are all required by HRA. An HRA installation involves using a large, heavy kettle for heating up the asphalt to 375-400°F, which can take three hours, and then keeping it hot during the waterproofing process. The kettle is heated with propane, adding both open flame and pressurized flammable gas hazards to the job site. The HRA itself can cause serious burns if it contacts the skin.

HRA installations require Hot Work permits for the duration of the application and beyond to assure fire risks are controlled. In some jurisdictions, there are also fire marshal restrictions for the jobsite.

In addition to heat and flame, HRA produces a noxious odor and fumes that can be disturbing and become a nuisance to neighbors, leading to complaints. More importantly, the level of VOCs HRA produces can be harmful and negatively impact the environment.

Cold-Applied Waterproofing

Cold-applied waterproofing pro-ducts, such as GCP’s Silcor hand-applied and spray-applied waterproofing, do not have these same physical hazards. The use of propane or flame are not necessary to prepare cold-applied materials and there are no hot kettles or buckets involved, making cold-applied waterproofing a safer, fire and burn-hazard free option without compromising performance.

The Time Factor

The total amount of time needed to complete the waterproofing system installation should be considered carefully when exploring the various product options. Commercial builders, designers, and architects should look closely at the time required for each step, from preparing the materials and substrate to applying the product and curing when evaluating the application. Each waterproofing system option is vastly different, especially when you compare cold-applied versus hot-applied waterproofing systems.

Sequencing is critical as certain jobs on a construction site need to be completed before others can be started and may take some time before enabling a return to service. In the case of waterproofing, the system needs to be fully dried or cured before anyone can enter the area to walk or perform work.

The time needed to complete a waterproofing job is especially vital in an emergency renovation or repair scenario. For example, if a multi-million (or billion) dollar commercial building in a city’s downtown has water from the roof or horizontal deck penetrating the penthouse below, there is a very short window of time (typically only 4 hours) to resolve the issue in order to keep the tenant happy and avoid significant internal damage.

When comparing cold-applied versus hot-applied liquid waterproofing systems, there are vast differences in the number of steps, what’s required for each step and, ultimately, the time needed to perform each step. Application guidelines, including the minimum concrete cure time and required preparation, are provided by the waterproofing product manufacturer and should be reviewed specifically for each project.

Preparation

Hot-applied waterproofing requires a crew to clean and prepare the substrate, then prime and detail. Detailing is a separate step, demanding a separate setup as an additional material (a polyester fabric) needs to be obtained and applied for the detailing process. In new construction the concrete must cure for a minimum of 28 days prior to beginning the preparation. It can take days to complete all the preparation required depending on the size and complexity of the project.

With cold-applied liquid water-proofing, there are some systems that can go on 14-day-old concrete. The crew cleans and prepares the substrate in the same way; however, the detailing is greatly simplified. Generally, these steps take one to two days depending on the project size and complexity, about a third of the time required for hot applied systems.

Cold-applied, such as GCP’s Silcor liquid waterproofing system, has 2 to 3 times faster preparation time than hot-applied. Waterproofing can begin seven days earlier than with traditional hot applied methods. This equates to a two week schedule savings over using a hot-applied process.

Application

Building the membrane with a hot-applied liquid waterproofing system requires five to six layers, including primer, rubberized asphalt and reinforcement, and the protection layers made of separate materials. In addition, there is the time needed — about three hours each day — to heat up the rubberized asphalt in a kettle and bring it to 375-400°F. The average hot-applied installation is 2,100 square feet per day in an open area, including primer, first ply, reinforcement, second ply, and protection board. The detail work is separate.

The cold-applied liquid water-proofing membrane requires only two to three layers including primer, which only takes 1.5 to 3 hours to apply. No reinforcement layer is required as the membrane is self-leveling. A comparable cold-applied installation covers 7,000 square feet per day, or more, including primer, membrane and details, and it requires a crew of only three installers.

The cold-applied liquid water-proofing application is clearly much simpler, saving time and labor compared to a hot-applied system. Also, the primer can serve as temporary waterproofing in the interim before the membrane is applied. There is virtually no preparation time needed for the membrane material as the crew only needs to mix the product components, per the manufacturer’s instructions, and they are ready to go. With fewer steps involved, cold-applied is 3.5 to 4 times faster to install than hot-applied.

Curing/Return to Service

The time that it takes for the hot-applied installation to cure or harden and for the surface to be ready for return to service can be up to 24 hours. Cold-applied installation can withstand foot traffic in as little as 2 hours and enables faster construction sequencing. Cold-applied can be 12 times faster than hot-applied to cure and enable a return to service.

Cold-applied liquid waterproofing is available in a spray-applied and a hand-applied version. With the spray-applied version, the liquid is simply mixed and applied. It’s a faster application than the hand-applied version, as it allows the crew to immediately apply a single membrane. With the hand-applied version, the liquid is poured onto the concrete surface and spread quickly and easily with a squeegee.

Conclusion

A waterproofing product is considered durable not only when it meets the six critical performance requirements, but also demonstrates the ability to handle jobsite conditions and maintain long-term performance in the service condition. In other words, it installs easily with minimal defects and is physically tough and chemically inert enough to handle the construction site abuse and long-term aging (from water, repetitive movement, etc.) to maintain its waterproofing integrity.

Since reactive cold-applied liquid waterproofing products have the flexibility to be uniquely formulated to a specific purpose, a well-designed cold-applied liquid waterproofing product can meet all the requirements to provide the long-term performance needed. With such a product, builders and architects can trust they have a superior and efficient waterproofing system that will provide a seamless, robust, and monolithic membrane that is more durable and longer-lasting, and will effectively and reliably seal and protect surfaces and structures from water penetration.

Cold-applied liquid waterproofing offers easy application free from the hazards that come with the heat and flame required by HRA applications. Time is money when it comes to meeting project schedules on construction sites. The time savings offered by cold-applied liquid waterproofing over hot-applied translates to cost savings in terms of labor, materials, and equipment rentals. Among the liquid waterproofing options, cold-applied not only saves time and money, it also provides a more durable product and a safer solution. Σ

Greg Austin is the global product director, specialty building materials, for GCP Applied Technologies. He has a background in consulting and almost a decade of experience in waterproofing system development and construction materials.

Winter 2022 Back Issue

$4.95

Cold Vs. Hot-Applied Liquid Applied Membranes and Coatings

Insulfoam’s Geofoam Completes Swimming Pool

Waterproofing Pool Decks

Largest Waterfront in the Southeast

Roofing Collaboration For Shriner’s International Project

Strengthening Your Waterproof Business

AVAILABLE AS PDF DOWNLOAD ONLY

Description

Description

Cold Vs. Hot-Applied Liquid Applied Membranes and Coatings

By Greg Austin

An expert in liquid applied membranes and coatings discusses the unique set of features and benefits to cold-applied and hot-applied waterproofing products. Which type is more durable?

Insulfoam’s Geofoam Completes Swimming Pool

The massive Midtown 360 425,000 square foot complex was designed to accommodate both residential and commercial real estate needs. And a major draw for potential residents is a luxurious outdoor swimming pool on the first floor of the building.

Waterproofing Pool Decks

By Vanessa Salvia

Concrete is more vulnerable than it seems, especially when it comes to water damage. Since a pool deck is constantly exposed to water, one of the first signs of damage to appear is cracks.

Largest Waterfront in the Southeast

By Meredith Cook

The city of St. Petersburg welcomed Floridians to a revitalized 26-acre attraction—St. Pete Pier. Serving as a premier destination for residents and visitors alike, the new pier hosts amenities ranging from an open-air market to performance spaces.

Roofing Collaboration For Shriner’s International Project

Polyglass U.S.A. Inc., a leading manufacturer of roofing and waterproofing systems, teamed up with D&D Roofing, a roofing contractor in Nevada, to provide a new roofing system for a Shriner’s Kerack in Reno.

Strengthening Your Waterproof Business

By Vanessa Salvia

The world has changed. Because of COVID and how that limited in-person interactions, yes, but even before that, online interactions were becoming more commonplace. So what can waterproofing companies do to keep themselves visible and relevant? Here are some ideas.

Additional Info

Additional information

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

|---|

Reviews

There are no reviews yet.