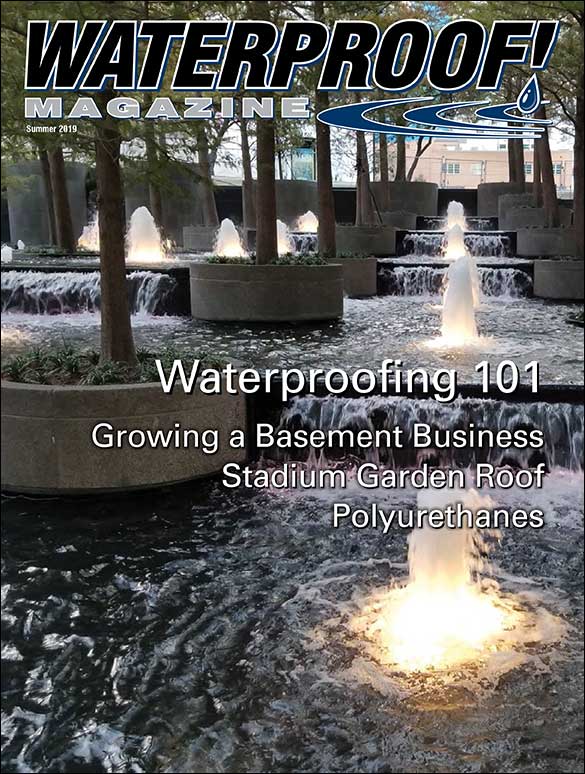

Renovations of the famed water features at Fountain Place focused on waterproofing with seamless, flexible, chemical and UV resistant coatings.

Fountain Place in Dallas, Texas is as well known for its beautiful fountains as it is for the building itself, a dramatically sculpted office tower of reflective glass.

A few years ago, these famed water features—consisting of nearly two acres of cascading waterfalls, pools, fountains, and elevated walkways— needed be renovated, and the building’s ownership group and primary engineer wanted a restoration that would be leakproof for as long as possible.

Gary Bennett, the owner’s representative for Fountain Place, says the water garden renovations were complicated by a couple of factors. “The water gardens were originally constructed above a parking garage with thousands of concrete cold joints, using separate pours not really designed to be waterproof,” he says. “The vertical to horizontal concrete components were sealed with various waterproofing products that were not completely designed for the conditions in which they were used.”

As a solution, they turned to a new breed of seamless, flexible coatings known as polyureas.

Mobile Enterprises, a specialty commercial contractor, was selected to do the work. John Pierce, executive vice president explains, “The original design used polyurethane-based elastomeric coatings. While these have UV resistant topcoats, over the past 20 years, exposure to chlorine in the water as well as outdoor UV rays begin to bake those membranes. They become soft, and chalky. They wear out, become susceptible to substrate movement, and prone to leaks.”

The parking deck’s top slab is made up of pre-cast planks with a topping slab, and as cars drive below looking for spaces, it causes movement in the garage structure.

Daily and seasonal temperature changes were also a factor. “Mid Texas summers are hot and winters are cold,” says Pierce. “This will cause water feature concrete expansion as higher temperature water flows over it in summer and contraction as colder water flows over it in winter. Thermal cycling between day and night can also cause some substrate movement as well.”

According to Bennett, all the substrate movement was well beyond the original waterproofing products’ capability to maintain constant waterproofing. An earlier repair using a PVC roofing membrane with heat welded seams still had leakage issues. Pierce ruled out materials like plaster, epoxy, or tile, as they were too rigid and would crack and leak.”

Fountain Place’s ownership group and primary engineer selected an elastomeric polyurea basecoat and topcoat combination from VersaFlex.

After removing all of the water feature materials down to the original structure, they made all the necessary repairs to the concrete substrate. Then they primed the water feature areas with a spray-applied, 60-mil polyurea basecoat to create a seamless, waterproof, durable protective liner that stops leaks and strengthens the integrity of the entire structure. The material offers high elongation, crack bridging, hardness, and tensile strength to create a robust, resilient, puncture resistant liner. It is also designed to withstand wide variations of temperature and decades of freeze-thaw cycling.

This was topped with a 20-mil coat of GelFlex, a 100% solids, UV-resistant polyurea topcoat. “GelFlex bonds seamlessly, tenaciously to the basecoat,” says Pierce. “It provides chemical and UV resistance as well as a high gloss, color stable, aesthetic look designed to last decades.”

Together, the polyurea basecoat and topcoat “provide a much tougher, more aesthetic membrane for the long haul than other softer elastomeric coatings,” adds Pierce.

The polyurea basecoat and topcoat were applied with a two component spray gun connected to a heated hose and pump machine. With this system, the components are mixed in the spray gun nozzle during application so there is no pre-mixing needed and essentially no waste in the process.

Pierce notes that the fast setting polyurea basecoat and topcoat offer application advantages as well. “Since they each set within 30 seconds, you can walk on them in a minute,” he says. “After an hour, you essentially have a fully cured membrane, so if you have some afternoon rain, it will not set your project back.”

“The polyurea basecoat and topcoat combination works really well, both functionally and aesthetically, for Fountain Place,” concludes Pierce. “Any property with water features – such as hotels, resorts, parks, convention centers, or commercial pools – would benefit from such an application.”

Summer 2019 Back Issue

$4.95

Growing A Basement Business

Below-Grade Waterproofing 101

Rehabbing Aging Concrete Wastewater Infrastructure

Green Roof for A Stadium

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Growing A Basement Business

By Vanessa Salvia

Contractors seeking to grow their waterproofing business have a number of options, including adding structural repair services, mold remediation, and sump pump servicing.

Below-Grade Waterproofing 101

By Kevin Smith

Selecting the appropriate below-grade waterproofing solution for your specific project and unique conditions is not always an obvious choice.

Rehabbing Aging Concrete Wastewater Infrastructure

Easy to apply and resistant to abrasion and chemicals, polyurethanes are becoming a popular choice for sealing water and wastewater tanks.

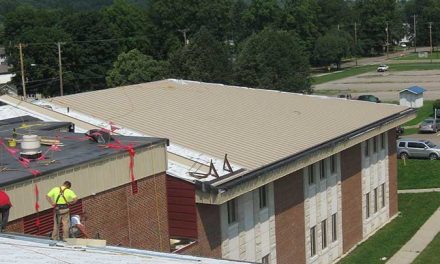

Green Roof for A Stadium

In the past few years, a number of exceptional green roof projects have been completed. One of the most notable features a vegetable garden atop America’s oldest baseball stadium.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|