Simplifying The Two Essentials Of A Planted Roof –By Michael McAuley

As waterproofing professionals know, one of the most crucial jobs of any roof system is to keep water out of the building.

With this in mind, it seems one of the last things a designer would want to do is create a landscaped park on the roof, as the added weight and moisture make it tougher to achieve a watertight roof assembly.

But garden roofs are growing in popularity, with 18% growth in square footage in 2015, according to Green Roofs for Healthy Cities. Washington, D.C., led the way that year, with nearly 1.6 million sq. ft. installed. Although D.C. has held the number one spot for five years, the green roof phenomenon isn’t limited to government buildings.

Some of America’s largest companies have installed green roofs. Ford’s Dearborn, Mich., truck plant final assembly building sports one of the world’s largest living roofs at 454,000 sq. ft.

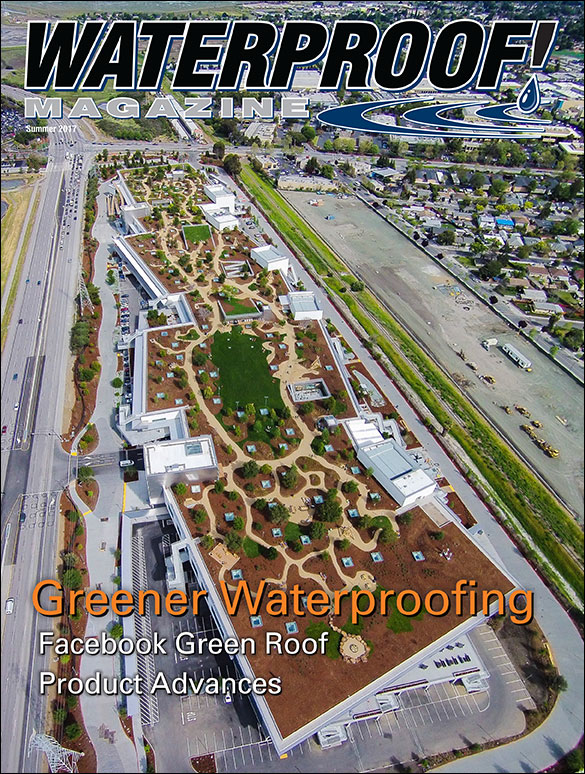

The finished landscaping of Facebook’s garden roof.

In 2015, Facebook opened its MPK 20 office building in Menlo Park, California, with a nine-acre living roof featuring more than 400 trees, a half-mile walking trail and small hills and valleys.

Increasingly, green roofs are using geosynthetic materials such as geofoam to help keep planted roofs light and watertight.

Green Roof Benefits

Building owners install planted roofs for a variety of reasons, ranging from reducing environmental impacts to creating an employee amenity.

“Green roofs are a key strategy for mitigating the heat island effect in our city and for effective stormwater management,” said Tommy Wells, director of the District of Columbia’s Department of Energy and Environment.

In Facebook’s case, the company’s head of human resources and recruiting says that the park-like roof, “gives space to think.”

Chicago’s Maggie Daley Park relies on EPS geofoam for lightweight landscape contours over a downtown parking garage.

From these statements, one might conclude that planted roofs are just the latest fad of granola crunchers. But, such roofs can deliver tangible financial benefits. Green roofs installed on commercial and public buildings provide a 224% return on investment and 5.2% internal rate of return, according to the U.S. General Services Administration (GSA). These benefits result from lower energy and stormwater management costs, less frequent roof replacement and job opportunity creation, according to the agency.

Overcoming Challenges

Adding plants and park-like amenities to a roof increases the complexity of the roofing assembly. Garden roofs present two primary challenges for building professionals to solve: minimizing the dead load and preventing moisture intrusion.

The project team for the Facebook MPK 20 building’s green roof met this two-fold need with expanded polystyrene (EPS) geofoam.

Weighing considerably less than soil, EPS geofoam is an ultra-lightweight engineered fill that can be used to create contoured landscape features such as hills and valleys. The material weighs from 0.7 to 2.85 lbs. per cubic foot, depending on the product type specified, compared to 110 to 120 lbs./cu. ft. for soil.

Despite its low weight, EPS geofoam is designed for strength, and has better load bearing capacity than most foundation soils. Geofoam’s compressive resistance ranges from approximately 2.2 psi to 18.6 psi (317 to 2,678 lbs./sq. ft.) at a 1% deformation, depending on the product.

EPS geofoam is also effective at addressing the second challenge of garden roofs, managing moisture absorption. The moisture performance of the various components in a green roof assembly is critical, as retained water imposes additional loads on the roof and increases the risk of water damage to the roof assembly. EPS geofoam which meets ASTM D6817 standards works well here as it only absorbs 2% to 4% moisture by volume, even over long-term exposure, and it dries quickly.

EPS geofoam creates lightweight landscape contours on the 9-acre planted roof of Facebook’s California headquarters.

The moisture performance of EPS has been demonstrated in extensive in-situ applications and real-world testing, including research conducted by the U.S. Army Cold Regions Research and Engineering Laboratory. After burying EPS in wetted soil for nearly three years, the lab found that the material absorbed only 1.7% moisture by volume.

In addition to enabling lightweight, durable landscape features and helping to defend against water, EPS geofoam provides thermal insulation in garden roofs. Roofing professionals have used EPS insulation in roof assemblies for decades, as it offers the highest R-value per dollar among rigid foam insulations.

Although not what one would traditionally think of as a “roof,” another prominent project in which EPS geofoam came to the rescue is Chicago’s Maggie Daley Park (See story in the Spring 2016 issue.) Much of the 20-acre downtown park overlies the East Monroe Street Parking Garage. The garage lacked sufficient structure to hold the park’s planned rolling hills and earthen landscape features, so the project team substituted soil with lightweight geofoam to form the ground contours. “[Geofoam] allows you the freedom to be creative,” the Chicago Sun-Times quotes designer Peter Schaudt.

Conclusion

Although green roofs currently account for a small portion of the billions of square feet of roofs in the U.S., we can expect to see more demand for them given their aesthetic, environmental and financial benefits. High-performance materials like EPS geofoam can help provide a watertight and light green roof assembly, for long-lasting durability.

Michael McAuley is president of Insulfoam (www.insulfoam.com). McAuley has more than 20 years of experience in building material sales and production management, including 14 years at Insulfoam’s sister company, Versico Roofing Systems, as the national sales manager and general manager.

Project Statistics

Name: Facebook Headquarters MPK 20

Location: Menlo Park, Ca.

Owner: Facebook Corp.

Cost: Undisclosed

Size: 430,000 sq. ft. (9 acres)

Completion Date: 2015

Roof Assembly: American Hydrotech

Geofoam Supplier: Insulfoam

Summer 2017 Back Issue

$4.95

Light and Tight: Facebook Green Roof

By Michael McAuley

Advances in Commercial Waterproofing

Greening Your Waterproofing

AVAILABLE AS PDF DOWNLOAD ONLY

Description

Description

Light and Tight: Facebook Green Roof

By Michael McAuley

The flat roof on Facebook’s new headquarters has a garden roof the size of seven football fields, and includes a half-mile walking path that winds through more than 400 full-size trees.

Advances in Commercial Waterproofing

From deep foundations to rooftops, new waterproofing technologies are helping create structures that are better-performing and more cost-effective than ever before.

Greening Your Waterproofing

The green building movement has raised expectations for waterproofing products, with a shift towards more eco-friendly solvents, easier recycling, and entirely new types of waterproofing.

Additional Info

Additional information

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

|---|

Reviews

There are no reviews yet.