An integral gel waterproofing solution was used to repair this floating concrete drydock. It was sprayed onto the cured concrete to create a long-lasting, durable waterproofing solution.

Integral gel waterproofing is also effective for repairing previously cast concrete. When leaks were discovered in the largest floating dry dock in Southeast Asia, crystalline waterproofing was used to perform long-term emergency repairs.

The dry dock was commissioned by a U.S. company, designed by a Singapore-based marine engineering company, and built in Indonesia at a cost of US$12 million before being floated across the Pacific to Hawaii.

Made from concrete with steel wing walls, it weighs 16,500 tons and is capable of accommodating ships up to 118 feet wide and weighing up to 10,500 tons. The primary concrete pontoon that allows it to float measures 14 feet tall, 451 feet long, and 151 feet wide.

Construction began in March 2016, and spanned 13 months. The process began with placing reinforcing bars and post-tensioning ducts. Crews then poured the pontoon base, then installed precast concrete silos and interconnecting fin walls, to form a honeycomb interior. Precast concrete planks were laid over the top, followed by a concrete topping course. When sufficiently cured, the entire structure was post-tensioned. Finally the 49-foot high steel wing walls were attached.

Shortly after putting the dry dock to sea, it was discovered that the concrete hull was leaking. The owners had to resolve the issue quickly. The solution was to use a heavy lift vessel to extract the dry dock from the sea and apply Alchemco’s Techcrete 2500 waterproofing solution.

Two four-member crews worked 12-hour shifts round the clock to ensure the job met the tight deadline, completing the entire 33,000-sq-ft waterproofing project within 26 hours, including cleaning and product application.

The team pressure-washed the entire hull in roughly five hours, then began applying the TechCrete 2500 waterproofing agent. It’s a sodium silicate solution designed to penetrate the concrete and increase its hardness. It seals cracks up to 2 mm in width, and pre-fixes anticipated cracks up to 0.4 mm in width in the future.

It works by reacting with free calcium in the concrete to form calcium silicate gel. This material fills the pores, cracks, and capillaries, and remains reactive to provide long-term protection against moisture. TechCrete’s accelerating agent was used, further hardening the surface and enhancing the sealing of cracks.

“Alchemco’s environmentally friendly product lines allow applicators to waterproof projects without fear of damaging the surrounding areas,” says Mario Baggio. “In this case, the fact that TechCrete 2500 is certified safe for potable water meant that this project could be done at sea, which satisfied Marisco’s critical timeline.

The project started at 9 a.m. and ended before noon the following day. Recent discussions with the project manager confirm no water leaks have appeared in the two years since application, despite floating in a corrosive saltwater environment 24 hours a day, seven days a week since returning to service. The design life of the concrete pontoon section is 200 years, which is why a proven, long-term waterproofing solution was critical. A video of the project is available at https://www.techcretesystem.com/videos.

Portions of this article were adapted with permission from “Southeast Asia’s Largest Concrete Floating Dry Dock Launched,” by Michelle Howard.

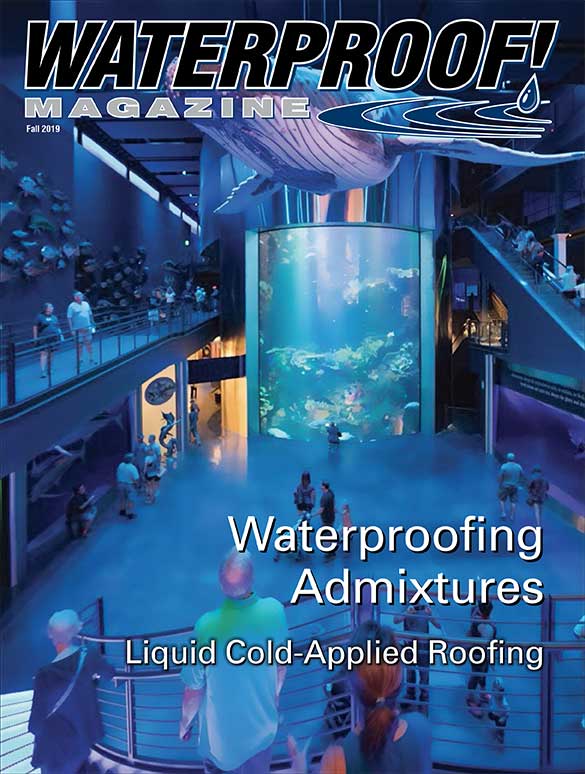

Fall 2019 Back Issue

$4.95 – $5.95

Admixtures as Waterproofing

Floating Dry Dock

Liquid Cold-Applied Roofing

Reflective Coating Saves Condo Roof

Waterproofing a Historic Stadium

Description

Description

Admixtures as Waterproofing

Integral waterproofing admixtures—including crystalline and various densifiers—have proven to be a great solution for new concrete construction.

Floating Dry Dock

Liquid Cold-Applied Roofing

Cold, fluid-applied roofing solutions offer a host of benefits, including improved safety, reduced fumes, less equipment, and faster cure times.

Reflective Coating Saves Condo Roof

By Karen Edwards

A reflective roof coating restored and extended the life of a Florida condo roof.

Waterproofing a Historic Stadium

When Kansas State University recently upgraded and modernized their historic football stadium, it called for a range of waterproofing solutions to seal everything from elevator pits to the roof

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

Reviews

There are no reviews yet.