Stronger than steel, and far easier to install, this space-age material is making basement structural repair a fast-growing and profitable niche.

Carbon fiber is one of the world’s most high performance materials.

Woven into sheets and impregnated with epoxy resin, these “carbon fiber-reinforced polymers” can withstand extremely high temperatures, and will not stretch. The material is extremely lightweight, yet ten times stronger than steel. (Aerospace-quality carbon fiber has a tensile strength higher than 700,000 lbs. per sq. in.!)

The material was first discovered in the 1950s, and not surprisingly, immediately caught the attention of the U.S. military. As the product was further refined, it was put to use in a wide array of uses. Today, it’s used to construct stealth bombers and drones, body armor, the heat-resistant re-entry shields on spacecraft, and to make emergency repairs on bridges, tanks, and other structures.

For decades, the military consumed most of the world supply. But by the late 1990s, carbon fiber was available commercially. Besides being used in high-performance sports equipment, a number of engineers realized that carbon fiber also had the potential to transform the world of basement structural repair.

Bob Thompson, a professional engineer based in Columbus, Ohio, partnered with his hunting buddy and fellow engineer Steve Morton to developed a system of carbon fiber straps to stop bowing basement walls. They incorporated Nationwide Reinforcing, Ltd. in the year 2000.

Several other companies developed different carbon-fiber-based repair products in the same time frame, and over the past 15 years, their popularity has skyrocketed.

Luke Secrest, vice-president of sales at Rhino Carbon Fiber, says, “Carbon fiber repairs are the fastest growing part of the foundation repair market ever. A quick internet search reveals all kinds of information on how governments are using it to reinforce most structures from buildings to bridges.”

Thompson estimates his company has engineered, distributed, installed and consulted on over 30,000 basement foundation wall repairs. “Today,” he says, “most structural engineers are using carbon fiber to design a variety of structural repairs. The most common use is in residential basements.”

The product is available as straps, in sheets of various sizes, and also as carbon fiber staples. Sheets can be unidirectional or bidirectional, depending on the intended application. StablWall, for instance, markets both straps and sheets, and Theresa Neitzel, reports that with more than 38 years in business, their earliest carbon fiber repairs are still as strong as the day they were laid up.

The Challenge

Wherever basements are found, some of those walls are going to bow. Thompson explains, “Up until the early 1990s, most homes were built without any kind of flexural reinforcement in the wall and therefore, are structurally inadequate. It is just a matter of time before the backfill dirt settles around the home, gutters become clogged and the hydrostatic pressure exceeds the strength of the unreinforced wall. This is when most home owners see a long horizontal crack in the middle third of their basement wall and call for help.” It’s more common with block walls, but poured concrete walls can also experience cracking.

Back in the year 2000, a professional structural engineer in Ohio named Kenneth Johnson examined a then-new carbon fiber product called StablWall, and neatly summarizes the challenge and traditional solutions:

“The pressure of the earth causes the concrete block to crack and bow inward. [Often] the pressure from ground freezing adds to the normal earth pressures. The magnitude of the pressure cannot easily be determined, but clearly exceeds the ability of an unreinforced masonry wall to resist.

“Through the years there have been several methods developed to stabilize these cracked walls. The more common methods include (1) installing vertical steel beams or channels to transfer the horizontal pressures to the floor slab and joints above. (2) Cut out a vertical chase and create a reinforced concrete pilaster. (3) Install earth anchors horizontally to provide a tie-back system for resisting earth pressure. (4) Remove and replace the entire damaged portion of the wall.”

He concludes, “All of the above corrective methods are costly, messy, and only partially successful at restraining a wall from further movement and cracking. Also none of these corrective measures address the basic engineering reason for the cracking: a lack of tensile strength in masonry.”

The Solution

Joe Dattilo, owner of Gateway Composites, says carbon fiber addresses this basic weakness of block/poured foundations. “One of the advantages of carbon fiber and the reason it’s continuing to grow in the market is that it restores the structural capacity of the wall. When a wall cracks, it loses its tensile strength. Carbon fiber is able to restore that, while steel beams do not. A steel beam or wall anchor adds a single anchor point, but it does not add tensile strength back to the wall.”

He continues, “Any time there’s a horizontal crack in the wall, it’s an indication that the wall is moving. Once it’s cracked, it continues to weaken, and much of that damage transfers to the structure where you live.”

Gateway Composites is a “raw materials company” specializing in the design and manufacture of carbon fiber products. And while they do not offer installation services, they do offer high quality carbon fiber fabrics, resins, and kits specifically designed and manufactured for basement repair. These tend to be relatively lightweight materials, weighing 200-800 grams per sq. meter. Depending on the application, unidirectional and bidirectional fabric constructions may be specified. Gateway also provides private labeling for contractors and distributors that want to promote their own brand.

“We’ve designed fabric specifically for the repair and rehabilitation of infrastructure, and we’re able to manufacture fabric that work specifically for commercial and residential rehabilitation applications,” he says.

Installation

Compared to steel beams, wall anchors, and other traditional wall stabilization methods, carbon fiber is quick and easy by comparison. However, it does require careful attention to detail, especially in the prep work.

First, the wall must be stabilized. Craig Bogard, manager of contractor development at Gateway, says, “If the structure is continuing to move, the cause of the settlement must be addressed prior to application of carbon fiber, using piers or whatever method the structural engineer specifies. Carbon fiber stabilizes and reinforces.”

The wide variety of carbon fiber products on the market have slightly different installation instructions. In general, once any settling is addressed and the location and size of the carbon fiber reinforcement is calculated, it’s time to fill the cracks.

Some manufacturers recommend “repointing” the wall, or filling the cracks with grout. Others recommend epoxy crack injection. Either way, the goal is to eliminate wall movement and create a smooth surface for maximum adhesion.

Next the wall is prepped where the carbon fiber will be applied.

“Surface prep is very, very important,” says Todd Jackson, owner of Fortress Stabilization. “You want to remove all the paint, dirt, and residue as well as the outer layer of cement paste and get down and expose the actual aggregate.” An angle grinder with a vacuum attachment or diamond-tipped sander is typically used, and for many, this is the most time-intensive part of the repair.

Concrete should be as dry as possible. If the wall is wet, the contractor will drill weep holes at the bottom to drain the wall, and then allow it to dry out. Even though there are resins that will cure in moisture, it likely will not cure with the properties needed for an effective repair.

Then it’s time for the actual lay-up. This begins with an epoxy primer coat, which is rolled onto the wall. “The primer is the bonding agent between the concrete and the carbon fiber” explains Neitzel.

At this point, installation instructions differ, based on the product. For instance, the unidirectional carbon strap from Fortress Stabilization is already encapsulated in a thermal set resin and cured under pressure during the manufacturing process, so once the wall is primed, it’s basically a peel-and-stick product. It’s available in 2-, 4-, and 6-inch widths.

Most products are “wet-laid” at the jobsite. This means the fabric must be completely impregnated with epoxy. A few manufacturers require a second coat of epoxy once the product is on the wall to ensure good adhesion.

The carbon fiber product must be applied so that the axis of strength is perpendicular to the crack. For stairstep cracks, that typically means using a bidirectional material. Neitzel, at StablWall, says they sometimes recommend applying two sheets, one horizontally and the other vertically to ensure adequate strength.

Once the epoxy has cured, the product can be painted or furred over. This is another major advantage of carbon fiber. It’s “thin as a dime” and requires zero maintenance.

What to Look For

Contractors wanting to add carbon fiber repair to their business have a host of options. Many companies offer training and certification. For instance, Nationwide Reinforcing has over 200 certified installers across the United States and Canada. A homeowner can simply type their five-digit ZIP code into their website and have access to the list of certified installers in their area.

StablWall offers customizable kits and customers can order materials in any length. “We sell the product to waterproofers and also install the product ourselves,” says Neitzel. We also educate homeowners on the advantages of carbon fiber repair.

At the other end of the spectrum, Gateway Composites has no installers, but provides raw materials, technical and sales support and training. They sells fabrics, resins, and kits under their own name and as private label products to contractors and waterproofing distributors.

Dattilo recommends getting a fabric with certified fiber properties that’s constructed specifically for the application. That means an appropriate weave, fabric weight and reliable fiber properties.

Similarly, contractors should use quality resins with a bonding strength that exceed that of the concrete. Dattilo recommends choosing a system with resins that are safe to handle, with no VOCs or solvents, and viscosities and working times for good wet out and easy installation.

Finally, choose a company with good technical support that will give installers the access to engineering and training, and will help with installation techniques.

He says “Good raw materials—fiber and resin designed for the application— will give the contractor the best chance of success. With the commercial and residential concrete repair market growing at such a rapid rate, its critical we provide the highest quality products and support to sell these products for continued market growth.”

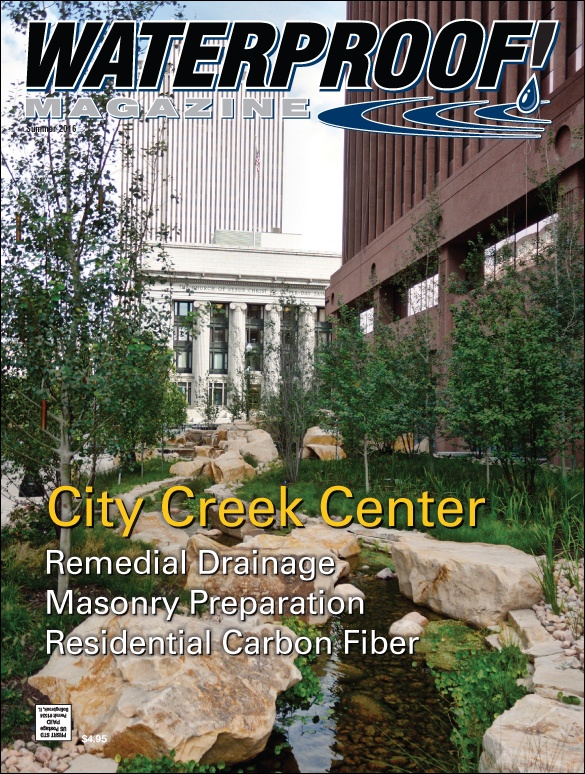

Summer 2016 Back Issue

$4.95

Remedial Drainage Options

Project Profile: City Creek Center

Residential Carbon Fiber

Preparing Masonry for Waterproofing

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Remedial Drainage Options

Wet basements can often be dried out and repaired from the interior. A range of products are available to simplify remediation and make below-grade living spaces habitable again.

Project Profile: City Creek Center

City Creek Center in downtown Salt Lake City, Utah, is one of the largest commercial developments in the U.S. Waterproofing the massive project was challenging, especially as it has a half-mile long creek flowing over the roof.

Residential Carbon Fiber

Stronger and less bulky than steel, this space-age material is making basement structural repair easier than ever before. Available as straps, staples, or sheets, it has been used on projects across the U.S.

Preparing Masonry for Waterproofing

By Don Foster

Sealing a masonry wall preserves it for all to see. A few simple procedures prior to sealing will ensure the structure looks its best for years to come.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|