PVC is used extensively in the construction industry; it is so omnipresent that people see PVC products almost every time they walk into a building.

A diverse range of items, including window and door frames, vinyl flooring and wall coverings, water pipes, ducts, fencing, and vinyl siding are all made of PVC.

PVC is also frequently used as a commercial roofing membrane. In fact, PVC was one of the very first single-ply roofing membranes. The first PVC roof was installed in Germany in 1966, and within a few years, millions of square feet of PVC roofing had been installed on buildings all over the world. The use of single-ply PVC roofing systems became widespread in the United States in the 1970s, particularly when the oil crisis drove up prices on the asphalt used in built-up roofing systems.

PVC has a reputation for versatility, quick installation time, durability, sustainability, excellent waterproofing properties, and superior chemical and fire resistance. Single-ply PVC has been used on many different types of buildings, including schools, airports, manufacturing facilities, warehouses, and restaurants.

Installation

A PVC roofing system is fast, easy, and economical to install, especially when compared to some other commercial roofing systems. This is mainly because of the minimal labor and few components that are required to install a PVC roof. The membrane is typically adhered to the roof substrate or mechanically fastened.

Most PVC roofs are fully adhered systems (in which the membrane is glued to an underlying substrate, often insulation or a coverboard), because it offers exceptional wind uplift properties and puncture resistance. PVC membranes are often used in roof garden assemblies as well, due to its toughness and outstanding waterproofing properties.

PVC systems can also be mechanically fastened (in which the membrane is screwed through the underlying substrate into the deck, as opposed to being glued on), which is a quick, clean attachment method that typically results in labor savings.

During the manufacturing process, plasticizers are added to the PVC membrane to enhance it’s flexibility, even in cold temperatures. The flexibility of the PVC membrane allows it to be installed in a wide range of temperature conditions, which gives general contractors and roofers some leeway in their schedules. These plasticizers also keep the membrane flexible over the long term, even when outdoor temperature fluctuations are extreme.

PVC is durable and provides superior resistance against foot traffic, punctures and tears. However, should any damage occur to the roof, it’s easily repaired. Once PVC membrane is heat-welded together, the seams are watertight and extremely strong. In fact, a properly welded seam is sturdier than the membrane itself.

In addition to offering many of the same properties as other popular single-ply membranes, including ease of installation, flexibility, and durability, PVC is the most resistant single-ply membrane to animal fat, grease, oil, jet fuel, and chemicals; substances which are more likely to compromise other types of roofing materials. This makes a PVC roof an especially popular choice for restaurants, industrial facilities, manufacturing plants, and airports. Additionally, PVC offers the best fire resistance of any roofing membrane; it is very difficult to ignite and will not sustain a flame.

Environmental Concerns

Another attractive feature of PVC is its sustainability. Since the 1980s, there have been more than 20 life-cycle evaluations comparing PVC building products to similar building products made of other materials, and PVC products were found to perform favorably in terms of energy efficiency, thermal insulating value, low contribution to greenhouse gases, and product durability. PVC membranes can be made highly reflective, which can help save energy and significantly reduce air conditioning costs.

PVC is the only thermoplastic that is not made of 100% fossil fuels. It is composed of roughly half natural gas and half salt water. In addition, PVC production requires the use of less fossil fuels than the production of other thermoplastics. PVC roofs have a long service life, but when they need to be replaced, the membrane is 100% recyclable. In fact, more than 99% of all manufactured vinyl compound ends up in a finished product, due to widespread post-consumer recycling.

Modern Enhancements

The basic formulation of PVC membranes have been unchanged for the past 35 years, but technological advancements in stabilizers and pigments have made the material better-suited for today’s roofing environments. Unlike today, earlier versions of PVC membranes utilized low-grade, liquid plasticizers in the manufacturing process. These plasticizers could migrate out of the membrane, possibly leaving it brittle, inflexible, and vulnerable to cracking. Today’s plasticizers offer significantly higher levels of performance, allowing some manufacturers to offer warranties up to 30 years on their highest-quality PVC roofing systems.

Even with significant advancements in liquid plasticizer performance, the threat of migration led chemists at DuPont to develop Elvaloy KEE (Ketone Ethylene Ester) as an alternative to liquid plasticizers. Elvaloy KEE is a solid, high molecular weight polymer that is designed not to migrate out of the PVC sheet. Plasticizers that stay in place help to ensure that the membrane remains flexible and pliable throughout its entire service life, even when subjected to harsh conditions and chemicals. The first PVC roof containing Elvaloy KEE was installed in Florida in 1977, and membranes have grown in popularity in the 35 years since introduction.

The addition of Elvaloy KEE to PVC membranes result in increased toughness, flexibility, and long-term impact resistance. PVC enhanced with Elvaloy KEE will stay flexible in temperatures ranging from 200°F to -30°F and will remain easy to weld, should repairs ever be necessary. Elvaloy also enhances UV resistance, improves weathering characteristics, and offers even greater resistance than standard PVC membrane against chemicals such as air conditioning coolants, jet fuel, and grease. PVC membrane with Elvaloy KEE picks up less dirt and remains cleaner longer, resulting in decreased maintenance and increased reflectivity for building owners. An added bonus for contractors is that PVC with Elvaloy KEE produces less smoke when being welded than standard PVC.

In spite of the success and effectiveness of Elvaloy KEE, many companies are currently working on developing newer and more eco-friendly plasticizers. New bio-based plasticizers are being developed as an alternative to phthalates (a commonly used PVC plasticizer). Bio-based plasticizers are made from renewable feedstocks, and their use will make PVC an even more sustainable and environmentally friendly roofing system.

Wide Variety

PVC is available in a variety of thicknesses, widths, colors, and reinforcements; the wide variety of PVC membranes on the market means that there is a PVC membrane which is ideally suited to almost any roofing project. PVC is also offered with a variety of different reinforcements: polyester reinforced membrane, fiberglass reinforced membrane, and fleece-backed membrane.

Since it was introduced to the market, more than 15 billion square feet of PVC membrane has been installed all over the world. Roofing professionals feel confident recommending and installing PVC roofing systems because of the material’s track record. It has performed exceptionally well for decades, and has gained the full confidence of architects and experts in the specifying community.

PVC roofing membranes continue to gain popularity and market share because they’re ideal for commercial applications: dependable seams, high reflectivity, superior physical attributes and resistance to water, chemicals, grease, fire and punctures. PVC is a great system for roofs that are subject to harsh conditions, yet demand high performance at a low life cycle cost.

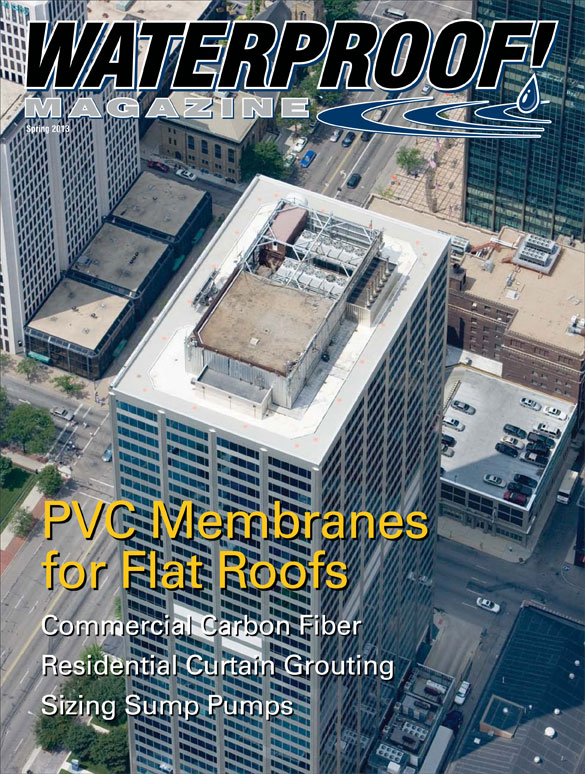

Spring 2013 Back Issue

$4.95

Properly Sizing Sump Pumps

Commercial Applications for Carbon Fiber:

Curtain Grouting in Residential Applications

PVC Membranes for Flat Roofs

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Properly Sizing Sump Pumps

By Duane Friend

Sump pumps are the heart of most drainage systems, and they must be properly matched to soil conditions, pit size and other factors to eliminate short-cycling while still providing enough capacity for peak events.

Commercial Applications for Carbon Fiber:

This space-age structural repair material is moving beyond basement repair into parking garages, high rises, and other commercial spaces.

Curtain Grouting in Residential Applications

By Melissa Morton

Injecting polyurethane grout through below-grade walls to stop active water leaks is common in commercial work. But the technique has applications in the residential sector as well.

PVC Membranes for Flat Roofs

By Tony Matter

As the original single-ply roof membrane, PVC has a long and proven history. It’s still the roofing membrane of choice for many flat roof projects.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|