By Melissa Morton

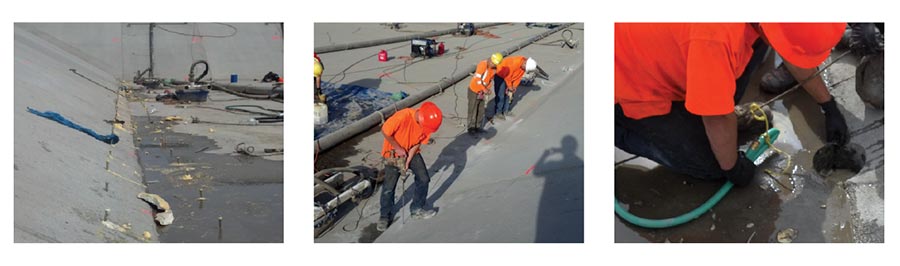

An innovative waterproofing technique known as curtain grouting was used to seal this wastewater retention pond.

Curtain grouting is a specialty waterproofing technique that’s extremely useful for stopping active leaks. It provides a permanent solution to situations where liquid water is flowing through the wall into the structure, and exterior excavation is cost prohibitive.

Often it’s an ideal method for stopping multiple leaks in underground structures located below the water table.

How it Works

Installing this type of system begins with drilling a series of small holes through the wall in the area of the leak. Then, an ultralow viscosity material is pumped through the holes, working from the bottom upward. On the exterior face of the wall, the material hardens and forms an impermeable curtain, all without the need to excavate or isolate the area from the ground water.

Curtain grouting is a similar technique to soil stabilization, as they both involve injecting material into the soil. “The difference between soil stabilization and curtain grouting is the desired outcome,” explains Charlie Lerman, technical services manager with Avanti. “Curtain grouting is used for waterproofing while soil stabilization is trying to achieve strength. Often a job is a combination of both.”

Curtain grouting is a similar technique to soil stabilization, as they both involve injecting material into the soil. “The difference between soil stabilization and curtain grouting is the desired outcome,” explains Charlie Lerman, technical services manager with Avanti. “Curtain grouting is used for waterproofing while soil stabilization is trying to achieve strength. Often a job is a combination of both.”

Curtain grouting is commonly used for restoring older structures. It’s also useful for remediating poorly installed concrete that has honeycombing or spider webbing with multiple cracks and leaks. At the most basic level, curtain grouting fills the voids around the foundation or structure with a wall of waterproof material. And it does so without having to excavate.

Note that because the system fills voids, special consideration should be given in situations where a foundation drain (French Drain) exists in order to avoid grouting the drain system.

Curtain grouting makes sense when it is cost effective or when there is no other fix. Cost effectiveness is determined by a range of variables. According to Edwin Brady, engineer and owner of Edwin Brady Construction in Paris, Ky., these variable include the grout material used, the type of soil, and the desired objectives.

Curtain grouting is most commonly used in industrial and civil work where excavation costs would be astronomical, such as tunnels, bridges, manholes, seawalls, subways, vaults, etc. However, it can be used in various applications, even in residential foundations.

Jobs that involve curtain grouting tend to fall into a few common situations:

When Traditional Methods Fail

Jim Tombarello, owner of Southern Concrete Repair in Jacksonville, Fla.,

does curtain grouting and soil stabilization work regularly. “The majority of my clients are specialty jobs,” Tombarello says. Often, his clients have already tried a few different waterproofing methods and they haven’t worked. “When they call me, I am their last resort,” he says.

Monica Rourke, owner of Dry Works, Inc., agrees that curtain grouting is often the last resort. She has specified and worked on many curtain grouting jobs; commonly they are specialty jobs with unique situations and problems. For instance, she was brought in as a consultant to help fix the New York City subway tunnels after the 9/11attacks that left them cracked and taking on water. Curtain grouting was the only method that would work in that situation.

“These are the jobs where the traditional methods just wouldn’t work,” she says. “Understanding curtain grouting is another tool for any waterproofing contractor’s toolbox. When they find the traditional methods won’t work, this is something that will.”

When Excavation Isn’t an Option

There are several reasons why contractors may not be able to excavate. Maybe the water table is too high or the job is located downtown in the middle of a city block. Lerman, the Avanti manager, says he has been on jobs where the EPA actually regulated the site because of the soil contaminants.

Sometimes just the nature of the job itself will prevent you from excavating. Tombarello runs into this situation a lot on his work on roller coasters in Florida. Excavating around the footers of a roller coaster wouldn’t be possible so he uses curtain grouting techniques. He’s done this type of repair work for Universal Studios, Disney World, Busch Gardens and Legoland.

“We are the roller coaster specialists,” he says. In fortifying the rides, he uses grout injection techniques to stabilize the soil that support the big footers that bear the weight of the roller coaster. “Basically, the concept of curtain grouting turns the soil into stone,” Tombarello explains. “You build a foundation around the foundation.”

When Concrete is Unsound

When a foundation wall is covered with excessive cracks or spalling, or when it’s honeycombed and/or spider webbed with hairline cracks, it may make sense to curtain grout.

“The best application of curtain grouting is when the entire wall is compromised,” says Craig Greenfield, senior technical sales, of Seal Boss. “Curtain grouting will manage difficult leaks without excavating,” he says. The idea behind curtain grouting is to build an impermeable curtain around the foundation so it doesn’t matter if the concrete continues to crack. It is important to note however, that curtain grouting addresses only the waterproofing aspect of the repair. Unsound structural concrete will need to be reinforced via other methods to restore it to the designed strength.

To Fill Voids

Often contractors use soil grouting to fill voids within the soil. Sometimes voids happen naturally while other times neighboring construction jobs disrupt the soil and cause problems.

Tombarello investigated one job where he found the cause to be a nearby construction site drilling pilings for a new transfer station. He ended up pumping 1,000 gallons of soil stabilization material around the 4,500 square foot house. He also stabilized the foundation walls with structural carbon fiber. “Needless to say the house stopped moving and won’t be going anywhere,” he says. “I told the owner if there was ever a nuclear war I want to be in his basement.”

To End Active Water Leaks

Curtain grouting is designed to isolate a structure from the ground water. It’s been known to stop active water leaks that had been flowing at thousands of gallons per minute. Brady, the Kentucky contractor, performed grouting on an large underground tunnel job where he shut off active water leaks totaling 12,000-15,000 gallons per minute.

Tombarello, the Florida contractor, was called to a unique jobsite where the work involved waterproofing a large water tank built over a natural spring. “Naturally water was seeping through the concrete structure. The owners even poured more concrete but the groundwater leaked through that too,” he says. “We injected more than 900 gallons of soil stabilizer. No more leaks.”

In Place Of Sheet Piling

Curtain grouting can accomplish some of the goals of sheet piling. While grouting isn’t intended for use as a retaining wall, it does work extremely well as a ground water barrier. In general, curtain grouting is better suited for restoration work and sheet pilings for new construction.

Erosion Prevention

Curtain grouting is often used in structures on the ocean, near lakes or other water sources. Chemical grouts can prevent erosion from the constant contact with water. This is why curtain grouting is commonly used to restore seawalls, docks and underground tunnels.

Curtain grouting can be used on jobs of all sizes from residential foundations to bridges and tunnels stretching for miles underground. While the concepts are similar, the specifics of every waterproofing job are different. “The water infiltration is different with every job,” Tombarello says. “There are a lot of variables to consider.”

Spring 2013 Back Issue

$4.95

Properly Sizing Sump Pumps

Commercial Applications for Carbon Fiber:

Curtain Grouting in Residential Applications

PVC Membranes for Flat Roofs

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Properly Sizing Sump Pumps

By Duane Friend

Sump pumps are the heart of most drainage systems, and they must be properly matched to soil conditions, pit size and other factors to eliminate short-cycling while still providing enough capacity for peak events.

Commercial Applications for Carbon Fiber:

This space-age structural repair material is moving beyond basement repair into parking garages, high rises, and other commercial spaces.

Curtain Grouting in Residential Applications

By Melissa Morton

Injecting polyurethane grout through below-grade walls to stop active water leaks is common in commercial work. But the technique has applications in the residential sector as well.

PVC Membranes for Flat Roofs

By Tony Matter

As the original single-ply roof membrane, PVC has a long and proven history. It’s still the roofing membrane of choice for many flat roof projects.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|