By Melissa Morton

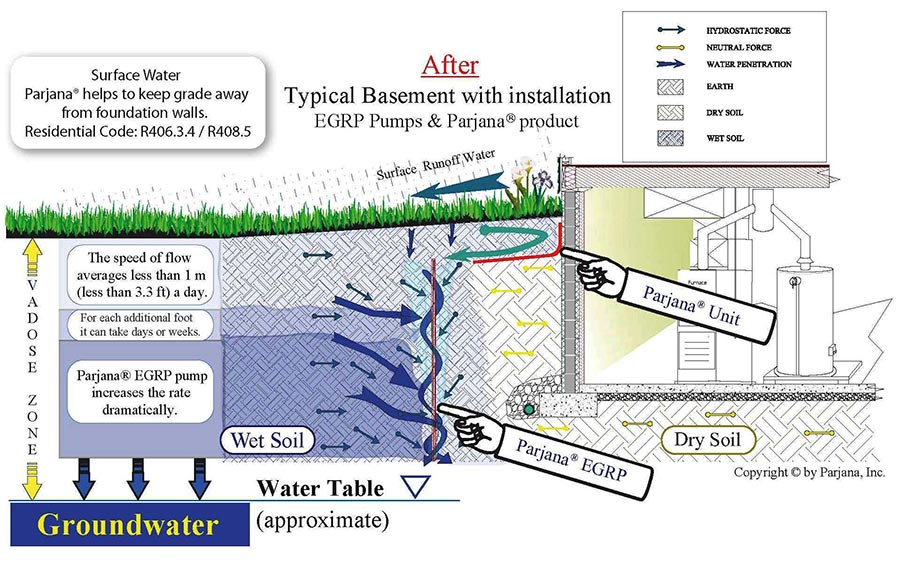

The non-electric EGR pumps are installed vertically in the ground with a drill. The pump the water down under the foundation to meet back up with the natural water table.

There is new technology that just may revolutionize the waterproofing and drainage industry. Parjana, Inc. has developed a non-electric pump designed to relieve hydrostatic pressure and push the water down below the foundation and back into the natural water cycle.

Parjana Inc’s new Energy-Passive Groundwater Recharge Pump (EGRP) is powered by the energy created from the soil as it expands and contracts. “It is hard to understand a pump that doesn’t run on electricity,” says inventor and owner Andrew Niemczyk, Parjana Inc., Southfield, Michigan. “The pumps have to run on energy; it is true. We are just using the energy from Mother Nature.”

“The earth itself has an energy,” he explains. “Think of a windmill as the wind pushes the blades and makes energy. Just as there is energy in the wind, there is energy inside the ground.”

The soil is constantly moving; expanding and contracting. When the soil gets wet it expands and as it dries it contracts. This pump is activated by that movement in the soil: hydrostatic pressure. When the pump is activated, it pulls the water away from the wall and pumps it down below the foundation to meet with the natural water table.

“Think of a human heart,” Niemczyk explains. “Always open but flexing to pump.” This pump works just like a heart: flexing with the pressure of the soil and pulling in the liquid through capillary action. Capillary action is the tendency of a liquid to rise in narrow tubes or to be drawn into small openings such as those between grains of a rock. Capillary action, also known as capillarity, is a result of the intermolecular attraction within the liquid and solid materials. The EGR pump uses the concept of capillary action to bring the water in.

The pumps are ten feet long and drilled into the ground around the perimeter of a basement. The pumps are installed with the top of the pump sitting a foot below the surface and backfilled with the regular soil. There is no need for excavation like other exterior waterproofing systems. Contractors just have to backfill where they drilled for the pumps.

The pumps pump the water down through the soil to the natural water table and back into the natural water cycle. “Often times, with other systems, the water is pumped into the sewer system or the storm drain where it has to be treated in order to use again,” Niemczyk says. “With this system, the water is not lost. It is pushed back into Nature’s water cycle.”

Patent Pending

This is the first pump of its kind and Niemczyk is in the process of patenting the system. He first developed the pump and started installing it in pilot sites seven years ago. During that time, Niemczyk installed the pump on basements and countless sites. He has never had a call back. “Once the system is installed you never have to go back,” he says. “There is no maintenance. Once it is done, it is done forever.”

There is no maintenance because it is self-cleaning. As the pump pulls the water through it siphons the water and cleans the pump. It doesn’t clog like other pump systems.

Most people once they understand how it works are concerned about the system clogging and tree roots, Niemczky says. Because the pump is directed down and there is no water sitting in the pump, the tree roots are not attracted it this pump like they are to French drains. Because this pump pulls the water from the soil, the tree roots redirect and go toward other water sources. The tree won’t die it will just adapt, he says.

This technology has been tested and works in all soil types and categories. “It will work on A, B, C and D soil classifications,” says Niemczyk. It can be installed to relieve hydrostatic pressure around all foundations (basements, crawlspaces or slabs).

During a residential install in Michigan, the soil around the home was completely saturated. Now that the EGR pumps were installed, the water has been redirected down under the foundation. After years of water problems, the basement doesn’t leak and the humidity levels allow for the owner to comfortably add carpet to the basement something he was always afraid to do.

In addition to the pump, Parjana has a water deflection panel. It is installed at the edge of the foundation. It is not nailed to the foundation so it can move with the soil. Together, the pump and the water deflection board make the complete Parjana waterproofing system.

Parjana also sells the drills to install the pump. Niemczyk is developing a prototype for his own drill for installing the EGR pumps.

Case Studies

One of his first pilot projects was Plum Brook Golf Course in Sterling Heights, Michigan. This particular golf course had three spots that would never drain properly. It was constantly saturated. No matter what they tried they could not keep these areas dry. Niemczyk installed his pumps around the perimeter of the problem areas and solved the issue. The owners of the golf course were amazed that a historically unusable part of the golf course is now dry and in use today. They installed the pumps five years ago.

Stan Marko, Concrete Water Solutions, Columbiaville, Michigan, started installing this new system about a year ago. “It really is the wave of the future,” he says. “It doesn’t depend on the current drainage system. Because it is not electric it is immune to problems of electric pumps.”

These pumps can be installed to solve almost every water problem. “I have seen it work to solve Iron Algae, high water tables (or what is thought of as though as a high water table—when the water is trapped between two upper layers of the soil) and Artesian Wells, where the water is bubbling up from the ground,” Marko says. It even solves humidity problems. Without dehumidifiers, this waterproofing system has created a 55% relative humidity in many Michigan basements.

This system replaces traditional waterproofing techniques for interior and exterior drainage applications. It removes the water from the soil around the house. The cost is typically less than traditional exterior systems. “While it does cost more than the typical interior system, it is a better system,” Marko says. “This system does not let the water come in at all. It keeps the water out and solves the cause.”

A residential basement in Michigan had a major problem with water seepage. The homeowner had two previous waterproofing systems installed in his basement—an interior and exterior system—and it still leaked. The soil was so saturated around the home that drilling for the EGR pumps was like drilling into mud. After one week from installing the EGR pumps, the homeowner reported his sump pumps have been running less each day. Progressively the water will dissipate and there won’t be enough hydrostatic pressure for the water to penetrate the basement walls.

Parjana’s water deflection board and EGR pump work together to dry out the soil underneath and around the perimeter of the foundation relieving the hydrostatic pressure that causes many basement water problems.

At another project in Michigan, Niemczyk is designing an application to fix an Artesian well that is bubbling up into the basement of a Michigan home. They are drilling down 50 feet and installing two pumps 25 feet down. All the water will be redirected down through the pump and will go out to a lake that is 40 feet lower than the house.

The EGR pumps can also be installed for new construction waterproofing. It removes the water from the soil preparing the ground for a new foundation, Niemczyk says. By removing the water from below the foundation, it will prevent future settlement; one of the typical causes of concrete cracks.

History

Niemczyk first learned about the soil and the earth’s energy in his work in a mine 3,936 feet underground, in Poland when he was younger. He was always fascinated by the soil formations and how the earth worked.

In 1997, he discovered a water problem in his own basement. He saw mold all over the walls and knew he couldn’t just live with it especially with his understanding of the effects of mold and moisture in relation to asthma and other health issues. He called many waterproofing companies to solve the problem. “Each company recommended something different; trench it on the inside, trench it on the outside,” he says. All these methods would work temporarily but no one could solve the actual problem. “I didn’t see the right answer,” he says. “No one could take the water away from the basement wall and remove the hydrostatic pressure that was causing the water seepage in my basement. I thought why can’t I bring the water down?”

That was when he started developing his idea for the EGR pumps. He flew to Italy and researched the history of the drainage systems there. He wanted to design and manufacture a pump that worked on the energy of the soil and was made from materials that would not release bad chemicals into the soil but also would not dissolve over 20-40 years. The pump is made of a durable plastic without additional chemicals or colors. It has been tested for environmental response to withstand temperatures at 20 below zero and not lose its shape.

Large Scale Applications

It has taken years of research and development to come to this point. Now he is ready to release the technology to the mainstream. Not only to the waterproofing and water drainage industry, but Niemczyk is also working with the U.S. government agencies to back his system for government and public community applications. This pump system can be used on a community wide level to recharge the natural ground water and handle storm drainage.

The Environmental Protection Agency (EPA) has given the green light on the system and is currently negotiating projects.

San Diego is looking to install the EGR pump systems to solve the city’s water run-off problems. Because of the large population combined with the little rainfall and city drainage issues, San Diego doesn’t have enough local water to supply to the people. This concept would recharge the natural water supply in the area and produce more clean water.

How to Learn More

Niemczyk is developing a training program and franchise opportunity to install these pumps and his waterproofing system. He says the best way to understand how these pumps work is to see a pump installation in person. He does pump installation demonstrations all across the country and is working to expand the company internationally.

For more information see www.parjana.com or call 248-351-8727

Fall 2011 Back Issue

$4.95

Options for Retention Ponds

Mold Remediation: An Update

Waterproofing Bridges and Overpasses

Mechanical Sump Pumps

AVAILABLE AS PDF DOWNLOAD ONLY

Description

Description

Options for Retention Ponds

Retention ponds are used for storing everything from stormwater to mining slurry. Others are used at refineries and sewage treatment plants. It’s absolutely essential that the pond liner be waterproof despite the often corrosive nature of the contents.

Mold Remediation: An Update

The excitement and litigation boom centering on mold and mildew has subsided, but the risks have not. Fortunately, new products and construction methods make it easier than ever before to ensure that your waterproofing jobs stay out of court.

Waterproofing Bridges and Overpasses

A modern mix of membranes, coatings, sealants, and waterstops help these structures stand up to heavy loads, temperature fluctuations, road salts, and harsh environmental conditions.

Mechanical Sump Pumps

Instead of electricity, this new sump pump relies on the pressure and flow of groundwater to provide power, eliminating electricity, batteries, and all the worries associated with them.

Additional Info

Additional information

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

|---|

Reviews

There are no reviews yet.