By Ron Greenbaum

Innovative materials and less construction mess are a few advantages these systems offer.

As waterproofing professionals and contractors, we have a responsibility to the homeowners we service to provide them with the best possible options when it comes to finishing their basements and creating comfortable, usable spaces in their homes. A mold and moisture-resistant panel finishing system can put you well on your way to doing just that, and save valuable time in the process.

The basement is unlike any other part of the home. While traditional wood and drywall construction work just fine for above-ground living areas, they can warp, rot and allow mold to grow in high-moisture areas like basements. Some basement finishing systems utilize inorganic materials designed specifically for the tricky basement environment. They are resistant to dampness, mold and mildew. They also allow for a faster, cleaner, more efficient installation process, with most systems boasting installation in half the time of traditional basement finishing.

It is important to note that not all systems can be painted or customized. With some panels, what you see is what you get in terms of color and texture, or you may have just two or three color options available. You might also have visible seams where the panels join together. There are systems, however, that can be painted or papered, and give the walls a seamless appearance no different than drywall.

With any remodeling or finishing project in the basement, homeowners can have specific demands when it comes to hanging items on the wall. Flat screen televisions, storage shelves or custom artwork are very popular in basements right now, and while most finishing systems allow for a substantial amount of weight to be hung on the wall panels, some require special hardware and may not carry the weight without special reinforcement.

While custom design options may vary among the systems, the benefits of using a panel system in the basement are many. Of course, not all systems are created equal. Each comes with its own benefits and challenges. In this article, I will evaluate four finishing systems and outline what features to look for when choosing a product for your customers.

Owens Corning

The originator of the panel finishing system concept, Owens Corning, has been offering a water- and mold-resistant solution for basement finishing since 2001. According to their marketing materials, the Owens Corning Basement Finishing System is a soft-wall system. It is comprised of lightweight R-11 fiberglass panels, PVC lineals (which replace conventional framing) and foamed PVC trim moldings (which replace wooden trim). The trim moldings snap into the lineals, holding the panels in place. The seams between panels are finished with small battens, which also lock the panels in place.

Owens Corning uses fabric-covered soft fiberglass panels, available in a single color.

“Our system is solely sold by us to homeowners, and it has to be installed by an Owens Corning certified installer that goes through specific training,” said marketing manager Carey Smeck. “The product comes with a lifetime warranty.”

The Owens Corning System features easy and speedy installation. Most systems are installed within two weeks, and come without the mess and dust of traditional drywall finishing. Like most systems, Owens Corning also comes with removable panels that allow for easy access to foundation walls, wiring and plumbing fixtures whenever necessary. With traditional methods, foundation work and rewiring are labor-intensive projects requiring demolition.

Designed specifically for basement conditions, the materials used in this system are breathable. When moisture is present, the walls actually “breath” and allow it to pass through instead of trapping or absorbing it. The Owens Corning insulation that makes up the walls keeps the basement warmer in the winter and cooler in the summer, which may add up to savings for homeowners.

The system’s 2½-inch-thick walls are certified with a .95 Noise Reduction Coefficient (NRC), which means almost all sound it comes in contact with is absorbed. This is compared to a .05 NRC for drywall. The drop ceiling specific to this systems is also designed to prevent sound from travelling up to the rest of the house.

Possible Challenges: The fabric panels used in this system can be torn and are available in just one color. The seams between the panels are visible, and the panels themselves require special hardware for hanging items up to 30 pounds.

The fiberglass insulation used will need to be replaced if it becomes wet. The dust that settles in the fiberglass is organic material and that has the potential to attract mold.

Basement Tuxedo

Like Owens Corning, the Basement Tuxedo finishing system was designed specifically with the basement environment in mind, meaning it is resistant to moisture, mold and mildew. The inside of each wall panel is made of one-pound structural closed cell foam with R-13 energy efficiency. The walls are designed to allow for a 1½ inch air gap between the foundation and the new wall. Basement Tuxedo uses a taping system to join each panel and the corners.

Basement Tuxedo has invisible joints, can be painted any color and easily supports wall hangings.

The wall panels that make up this system are available in two colors with the option to customize your walls through paint. The panels are also built to hold the weight of artwork and flat panel televisions. These panels can be easily removed for service to basement walls and are built to accommodate electrical wiring so that it is hidden from view.

A unique taping system hides the seams between the panels, so the room looks like a traditionally drywalled one, and the entire project can be installed in as little as one week depending upon the scope of the project.

Possible Challenges: While this panel has tape at the seams to give it the look of drywall, the seams are visibly different than that of the upper levels of the home. The adhesive on the tape can support microbial activity if it gets wet, and the panels themselves are heavy.

Total Basement Finishing

Total Basement Finishing (TBF) offers a complete basement remodeling package comprised of insulated walls, waterproof floors and sag-proof ceilings.

TBF panels are rigid, paintable, and strong enough to support a flat-screen TV. However, panel seams remain visible.

The wall system is rated R-13. TBF basement walls are built with a concrete core instead of foam, and have a washable finished surface, rather than fabric. The walls are rigid, waterproof, non-absorbent, and inorganic. Additionally, they can be painted or wallpapered to a homeowner’s design preference, and are able to withstand hanging items such as flat screen televisions, artwork and shelving without special hardware.

The wall surface is pre-textured, and can be painted in any color.

For flooring, the system uses ThermalDry tiles, which creates a break between the finished basement area and the unfinished concrete floor, warming the floor and allowing the space to be more effectively heated. These tiles also prevent moisture from seeping into the carpet. ThermalDry flooring is designed not to warp, bow or delaminate like wood products, and individual tiles can be removed for cleaning, replacement or to provide access to the concrete floor.

Possible Challenges: Like the Owens Corning system, TBF leaves visible seams in the finished wall. And while TBF is a very effective form of basement finishing, it is the most costly of the options reviewed. The panels are very heavy. This can increase shipping costs and make the panels hard to maneuver in the home.

Magic Wall

Magic Wall is a truly customizable basement finishing system that was designed to be used below-grade with water and mold-resistant R-16 rigid polystyrene foam insulation. The system creates a waterproof barrier between the living space and a damp foundation wall. Due to the type of insulation used (XPS), this panel will not lose R-value over time due to water absorption. The bottom edge of the wall system sits on waterproof, mold-resistant risers that protect the finished wall from water damage. Furthermore, the panels are manufactured with Borax in the insulation to make the panel resistant to termites.

“Magic Wall does not waterproof your basement, but it is designed to work perfectly with a waterproofing system,” said Otto Fleck, founder and CEO of DryBasement Waterproofing Systems. “Magic Wall is absolutely mold and moisture-resistant because of the inorganic materials used and it is designed for the basement specifically.”

Fleck’s company designed the system with the intention of creating an environment in the basement that is the same as upstairs but without all of the challenges usually present in the basement. With the Magic Wall System, walls are smooth, seamless, and can be painted a client’s color of choice. The engineered walls exceed building code by four times, meaning TVs and shelving systems can be hung without worrying about the structural integrity of the wall. The Magic Wall System also creates a straight interior wall even if the foundation wall is curved from age or soil settlement.

Magic wall is the heaviest system, and uses conventional drywall.

While gaining the benefits of a basement finishing system can mean a larger investment for homeowners, Fleck said Magic Wall and its moisture barrier can actually save money each month on heating and cooling bills by up to 33%.

“If you live in the home for more than 10 years, essentially the utility company has paid for the remodel with the savings on your utility bills,” he said.

Possible Challenges: Because Magic Wall is a combination of traditional basement finishing and a paneling system, there are some conventional materials used. Should the basement flood more than a couple of inches, some of the drywall may need to be replaced. However, the panel itself will require no repair.

While wood and/or metal stud finishing is still the most common form of basement finishing, these four popular systems demonstrate some of the advantages basement kits offer.

Prefabricated systems do cost more than conventional framing, but they can speed up the installation time, recouping some of the increased cost by reducing labor expenses. They may also create a healthier living space.

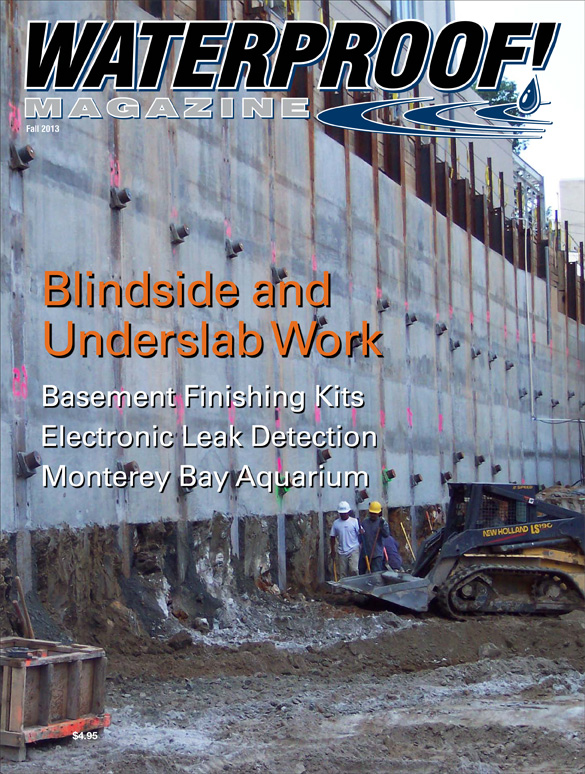

Fall 2013 Back Issue

$4.95

Electronic Leak Detection: High Vs. Low Voltage

Basement Finishing Kits

Blindside And Underslab Work

Project Profile: Monterey Bay Aquarium

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Electronic Leak Detection: High Vs. Low Voltage

The need to quickly find and repair leaks in roofing membranes has never been higher. Two new electronic leak detection methods are rapidly gaining popularity because they can locate even the smallest leaks with pinpoint accuracy.

Basement Finishing Kits

By Ron Greenbaum

It’s now easier than ever to offer basement finishing services. A number of companies offer innovative prefinished “kits” that make this a profitable service for many waterproofing contractors.

Blindside And Underslab Work

Projects that require waterproofing to be installed before the structural concrete require reliable, durable products, and flawless workmanship.

Project Profile: Monterey Bay Aquarium

By Steven H. Miller

Rebuilding and sealing a million-gallon aquarium tank was challenging—especially with a tight timetable and a requirement for non-toxic materials.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|