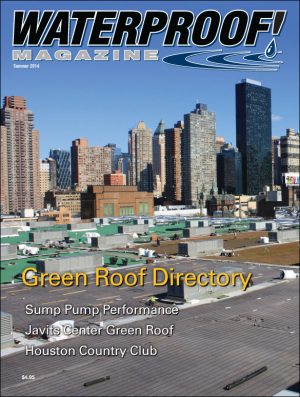

Fashion Valley Mall near San Diego, features this 18’ tall and 51’ wide green wall with 4,000 plants. It uses a system from Tournesol Siteworks

No longer satisfied with green roofs, designers are now developing vertical gardens and green walls, which require a new approach to waterproofing.

Converting an ordinary low-slope roof to a vegetated green roof offers a host of benefits, including improved energy efficiency, better stormwater retention, and an improved quality of life for building occupants—especially if it’s accessible.

Over the past decade, innovative engineers have tinkered with ways to extend these same benefits to vertical surfaces, and have succeeded in developing some rather astounding projects. Like their green roof counterparts, green walls require careful engineering and particular attention to waterproofing

Dave MacKenzie, horticulturalist and president LiveWall, LLC, says, “Transforming an ordinary wall into a vertical green landscape adds a living, organic element to a building. Green walls are visually appealing, inviting, inspiring, healthful, and beneficial to the environment (especially for moderating the urban heat island effect).”

He notes that building owners have been covering walls with living plants for centuries, using trellises for smaller flowing plants and ivy for larger multi-story buildings. “Ivy-covered walls are the most traditional form of green wall,” he says, “But they lack colorful flowers, and in some climates, can be aggressive. There is only so much creativity that a landscape architect can bring to a green wall design when constrained to using only vines.”

In contrast, these newly developed green wall systems can support a variety of plants — annuals, perennials, succulents, tropical plants and even herbs and vegetables. And instead of taking years to grow into place, they can form a complete green wall from day one.

At least seven companies manufacture or market green wall systems. About half are based in Australia. Nedlaw Living Walls, which claims to be the largest, is based in Ontario, Canada. Most of the others, including LiveWall, are based in the U.S.

These green wall systems can be divided into two broad categories. The first uses a metal trellis or network of steel cables attached to the side of building to support vines that grow from the ground up. The other type uses containers full of engineered growing medium anchored to the wall. This second system provides soil for the plants all the way up the height of the installation.

This 22-foot-wide, 80-foot-high living wall is one of the largest in the united States. Installed at Drexel University in Philadelphia, it’s improving air quality by 80%.

MacKenzie, at LiveWall, cautions that the soil-based systems need to be properly engineered for plant health. “Most plants just do not do well when forced to grow sideways… The reason that window boxes work so well is that they provide proper orientation for roots and stems and allow for rain-like irrigation. The engineering challenge was to design a vertical system that we could scale up and make it practical to install and maintain an entire planted wall with perhaps hundreds of boxes.”

The largest green wall to date is growing on the exterior of the Los Cabos International Convention Center near Cabo San Lucas, Mexico. Completed in 2012, the plants covers 29,063 sq.ft. (2,700 m2) of wall. It uses a custom green wall system with a thin layer of engineered soil the entire height of the 20-foot walls.

U.S. projects are more modest. One of the largest is in Philidelphia. In 2011, Drexel University installed a five-story tall 1,500-sq.-ft. green wall in the sky-lit indoor atrium of their science building. The 22-foot-wide, 80-foot-high living wall is integrated into the building’s HVAC system, and has the potential to provide 75% to 80% of the building’s fresh air intake requirement. It’s already achieving an 80% air quality improvement and 30% reduction in energy consumption. The wall uses a soil-based system from Nedlaw Living Walls. For irrigation, water is pumped to the top of the wall, where it trickles down through the growth media, eventually reaching a reservoir at the base to be pumped to the top again.

A notable outdoor living wall was recently installed at Fashion Valley Mall, an open-air shopping mall near San Diego, California. The 800 sq. ft. project (18’ tall and 51’ wide) utilized 4,000 plants, which were grown offsite for four months before being installed at the jobsite. It uses a soil-based VGM planting system by Tournesol Siteworks. Meant to resemble the keys on a piano, plants include ferns, Ajuga, moneywort and mondo grass.

MacKenzie estimates living walls cost about $100 per square foot, depending upon the size of the system, local labor rates, and the type of plants.

Winter 2014 Back Issue

$4.95

Selecting a Spray-Applied Air Barrier

The Importance of Dehumidifiers

Crystalline Solutions for Wastewater Plants

A Different Direction: Green Walls

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Selecting a Spray-Applied Air Barrier

by Colin Szewaga

Air barriers are becoming more common because they reduce energy use and many codes now require them. Fluid-applied membranes are especially popular because of their continuity, strength, and airtightness.

The Importance of Dehumidifiers

Dehumidifiers are often a critical component of a waterproofing system. But determining their size, placement and features is an essential part of making sure the units perform as intended.

Crystalline Solutions for Wastewater Plants

Waterproofing and sealing wastewater treatment facilities are difficult because of the constant immersion, extreme head pressure, and sometimes caustic chemicals.

A Different Direction: Green Walls

No longer satisfied with green roofs, designers are now developing vertical gardens and green walls, which require a new approach to waterproofing.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|