By ISI Building Products

Photos courtesy ISI Building Products

Smart Crawl Space Encapsulation

Outside construction trades and building science circles, few homeowners grasp how impactful the crawl space can be to the overall health of a structure. Since nearly 30 million U.S. homes contain crawl spaces, understanding how to properly monitor and maintain them is important. Let’s explore how an encapsulation project in Ocean City, New Jersey, turned a problematic area into a bright, clean “smart space.”

About the Area

Ocean City is located about 30 minutes south of Atlantic City and is coined “America’s Greatest Family Resort,” frequently winning awards for its beaches, boardwalk, and entertainment. The municipality occupies a barrier island with its eastern edge consisting of an 8-mile stretch of prime ocean waterfront. During the summer months, the island’s 11,000 permanent residents welcome hundreds of thousands of visitors.

Reason for Encapsulation

Residing near a large body of water has obvious benefits but is not without risk. No one knows this better than Ocean City resident Mike Graham, CEO of Smart Vent Engineered Flood Vents. He has seen first hand the damage rising waters and storm surge can cause to buildings. Graham’s products are designed to reduce stress on foundations by allowing flood waters into the space, creating equal pressure on both sides of the wall during a high water event.

“Our vent business has given us opportunities to be inside a lot of crawl spaces,” said Graham. “While flood proofing is our primary concern, we appreciate the need for properly encapsulated crawls. With my home I wanted to do it right.”

In the case of Graham’s home, chronic high humidity inside the crawl space had begun to cause insulation degradation, mold-like growth on the floor joists and musty smells upstairs. In the summer, condensation could be seen dripping from cold water lines onto the crawl space floor. Given his background in flood protection, Graham knew it was time for a crawl space renovation project.

Project Design

As a construction professional, Graham was determined to find the right formula for a high-performance crawl space. He knew a quality job would involve several components working together. The first task was to identify an experienced contractor to manage the project. After an extensive search, Termiguard was selected to help design the system and handle the install. During the design phase, Termiguard owner Mike Allen proposed the concept of a “smart crawlspace.” To start, fiberglass insulation would be replaced with water resistant foam insulation. The thermal boundary of the home would move to the walls creating a semi-conditioned environment inside the crawl space. Viper CS 16-mil vapor barrier was selected to replace aging 6-mil poly. This ultra-tough membrane prevents bulk water vapor and soil gasses from migrating into the space from the ground and through the block walls. It is puncture resistant, extremely difficult to tear and comes with a lifetime material warranty. Its durability and track record make Viper CS a great choice for an area needing to withstand foot traffic from maintenance, storage and periodic inspections.

A Sante Fe Ultra98 Dehumidifier, drain piped to the exterior, was specified to tackle excess humidity. The dehumidifier is equipped with the ability to remove 98 pints of water per day and is warranted for 6 years. To ensure good air circulation in the space, a corner fan was also included in the plans. The design team did not stop there. They also specified an Atmox control and sensor package to serve as the “central nervous system” for the crawl space mechanicals, calling for natural ventilation when exterior conditions were dry and relying on the dehumidifier when relative humidity levels were elevated outside.

To cap off the system, Smart Vent’s insulated flood vents would be installed as an energy efficient way to prevent structural damage from high water.

Workflow/Execution

Install began with some basic organization and cleanup measures. Like most crawl spaces, past utility contractors appeared to have treated the crawl space as “out of sight, out of mind” territory. Stray wiring, ethernet cables and piping were organized and secured to framing. Fiberglass insulation was removed and crawl space dirt and gravel was re-graded to provide for a more level working area. Exterior downspouts were extended to direct rainwater away from the foundation and rough openings were cut for the flood vents/mechanical ventilation. Mold remediation was performed next by Termiguard. A mold and fungus cleaning solution was applied to floor joists and excess biological growth was removed. The solution also protects joists from future growth and dries clear so framing remains visible for inspection.

R-10 foundation insulation was then applied to the foundation walls and band joists were insulated with new fiberglass insulation. Old openings were sealed up and pipe/wire penetrations were sealed with one-component foam. Viper CS was then installed over the wall insulation and on the floor to encapsulate the space. Seams were overlapped and taped to create a monolithic barrier.

Setting up the Santa Fe dehumidifier, connecting the Atmox sensor package and integrating the flood vents were the final step in the installation process. The insulated flood vents stay closed and sealed unless activated by flood waters. Mechanical air vents, controlled by the Atmox system, create natural ventilation when favorable conditions exist outside and humidity levels exceed 60% inside. If relative humidity conditions are above 60% outside, Atmox keeps the vents closed and calls for the dehumidifier to kick on until relative humidity inside the crawl space stabilizes.

Results

One benefit of the Atmox sensor suite is the ability to continuously monitor key crawl space metrics like temperature and relative humidity. Less than a week after the install was completed, the newly encapsulated space faced its first major test as the remnants of Hurricane Ian pummeled Ocean City with high winds and heavy rain. Water levels rose high enough that Mike’s street and front yard became fully submerged. Despite the soggy conditions outside, the crawl space never exceeded 70% relative humidity and remained warmer than the outside. Not only is the encapsulation performing as advertised, it also creates a much brighter and cleaner space. No longer is the crawl space a dirty, smelly area to be kept “out of sight.” In fact, Graham plans to show everyone in the neighborhood how good a crawl space can look. Factor in the improvement in indoor air quality, increased energy efficiency and peace of mind he now has during flood season, and Graham knows this investment was a good one.

Winter 2024 Back Issue

$4.95 – $5.95

AI in the Waterproofing Industry

Case Study: Northwestern University’s Simpson Querrey Biomedical Research Center

Installing and Protecting Green Roofs

Protecting the Commercial Building Envelope

Understanding Hydrostatic Pressure

Employer Responsibilities To Employees and Law

By Gregory Fahrenbruch

Description

Description

Trade Show Preview

When the new year rolls around, so does the trade show schedule. Here are lists of the booths that relate to the waterproofing industry for World of Concrete, the International Builders’ Show, and the International Roofing Expo.

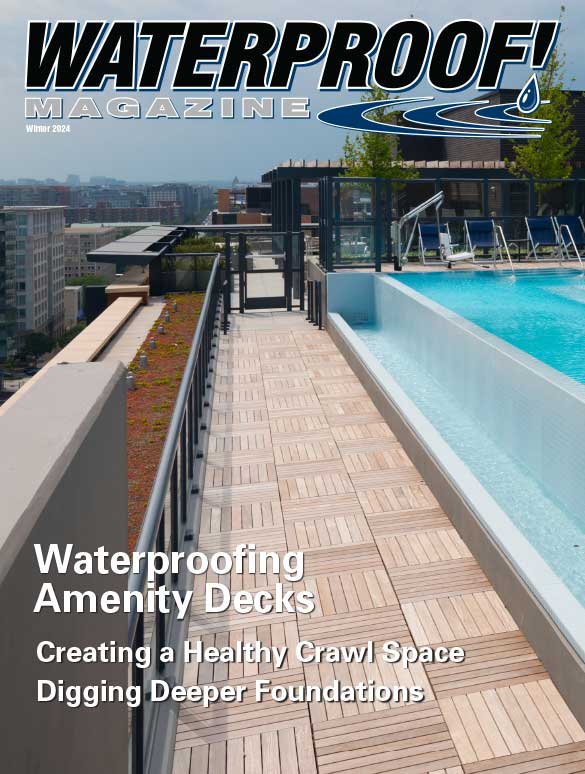

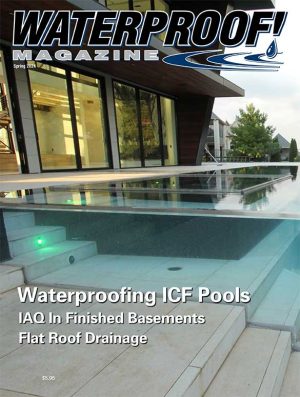

Waterproofing Amenity Decks

By Richard C. Hayden

Building owners and developers are continuing to place increasing value on the roof spaces that every building needs. In the increasingly competitive real estate market, building owners are demanding that the roof space function at a much higher level.

Creating a Healthy Crawl Space

By Patrick Nevison, P.E.

Healthy crawl spaces are ones in which excess moisture and radon are dealt with, among other things. Moisture and radon in a crawl space can lead to several issues throughout the home.

Case Study: Smart Crawl Space In New Jersey

By ISI Building Products

Outside construction trades and building science circles, few homeowners grasp how impactful the crawl space can be to the overall health of a structure.

Digging Deeper Foundations

By Iltaz Alam

With space at a premium in many urban areas, developers are digging deeper foundations to increase the square footage of high end residential, commercial and mixed-use building projects.

Case Study: Washington, D.C.’s Florida Ave. NE

By Scott Schendel

EPRO was recently involved in a critical project located in an up-and-coming area of the city, called Florida Avenue NE. This corridor has multiple land uses and several critical public transit connections and is also experiencing a high level of new development.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

Reviews

There are no reviews yet.