by Kelly Franklin

“Cold-applied roof system” originally meant a built-up roof that did not require heat to install, but today it encompasses cold adhesive bitumen membranes and liquid-applied membranes as well.

A Brief History

During the middle of the 19th century, modern roofing as we know it began to take shape when rag felt soaked in tar was layered with hot-mopped tar and covered with gravel. Over time, the tar was mostly replace by asphalt and the rag felt by fiberglass mat to create the modern-day built-up roof (BUR). In the middle part of the 20th century, it was realized that cold-applied roof adhesives could be used to adhere the plies of roofing felt, and the use of hot asphalt and roofing kettles could be avoided: The first cold-applied membrane roofing system had been invented.

According to Jason Smith, senior R&D chemist at the Garland Company, cold-applied roof systems refer to roofs that are adhered with an adhesive that doesn’t need to be heated prior to its application. They are used right out of the drum or pail and applied using a notched squeegee, or also by brush, spray, or roller, depending on the viscosity of the product. Cold-applied adhesives were developed in the mid-1970s using solvated asphalt, also called “cutback” asphalt, largely in response to projects where traditional kettle-melted asphalt could not be used.

Lee Martucci, product manager at GAF, notes, “The technology was developed as a way to counter concerns over potentially dangerous hot asphalt and fumes. When installing a roof without the big, messy hot kettles and fumes, the environmental and health concerns from the pubic lessen. Plus, contractors can install the membrane systems without investing in expensive kettles: all they need is a squeegee.”

Cold-applied roofing eliminates messy hot tar kettles and the associated fumes, which creates a safer jobsite and less irritation for the building occupants.

There are several additional benefits to cold-applied roof systems. George Daisey, a research scientist at Dow Chemical Company, points out that cold-applied roof installations allow for safer handling of materials, as there is no hot container to be hoisted onto the roof. Similarly, the application process removes the potential for burns or respiratory irritation from hot fumes. Overall, cold-applied roof systems result in a lower level of odor at the job site, which Martucci indicates can result in fewer complaints from building occupants. Smith adds that the job preparation is easier with cold-applied roofing installations: “often times, opening a bucket, pouring, and spreading is all that is required.” Furthermore, the cleanup requires only that the squeegee be cleaned and the pails and drums be disposed of. With much less equipment needed than in a hot-applied roofing job, the overall equipment costs are drastically lower.

Smith, at Garland, points out that cold-applied roof systems can be formulated to have lower volatile organic compound (VOC) emissions, which can be of significance in VOC-restricted areas like California and much of the northeastern U.S. Additionally, the products can be formulated to set chemically over time, forming a bond line that will not re-melt even on the hottest days.

According to Daisey, the term “cold-applied roof system” was originally used to describe a solvent-based built-up roof that did not require heat to install. Today, the term has broadened significantly as a variety of technologies have been developed to encompass the variety of roofing systems that do not require heating to be installed. These include traditional cold process built up roof systems, cold adhesive bitumen membranes, and liquid-applied membranes.

Types

Cold-Process Built-Up Roofing uses heavyweight asphalt-impregnated fiberglass base sheets adhere in multiple plies with solvent-borne asphalt adhesives. The first sheet is usually mechanically attached to the substrate (normally insulation) and subsequent plies (usually three or four total) are embedded in an application of adhesive at a rate typically between 1.5 and 2.5 gallons per 100 sq. ft.

Cold-process BUR uses solvent-based asphalt adhesives to adhere multiple layers of base sheet without heat. The membrane is then covered with aggregate.

Once the waterproofing layer is in place, the membrane is covered with an aggregate surface or roof coating.

Modified Bitumen Roofing is an adaptation of “torch-down” roofing. Modified bitumen roofs were traditionally installed using a propane torch to melt the back of the sheet, creating a molten adhesive in which the roll could be embedded. The “cold” version uses polymer-modified bitumen to achieve improved characteristics and eliminate the torch altogether. For obvious safety reasons, use of cold-applied roofing has provided an attractive alternative to the use of hot asphalt or open flame. These roofs typically have a mechanically attached base sheet, and one or two plies of modified bitumen membrane installed in bituminous adhesives.

Smith describes these adhesives as “rubber-modified fibered solvated asphalt adhesives that dry via solvent evaporation.”

Martucci adds, “These constructions typically consist of asphalt/solvent blends applied by a squeegee to adhere the membranes to the substrate of other membranes, although there are other technologies that can be used. There are also two-part blends that are a reactive cure and therefore set up much more quickly, although these technologies are more expensive.”

An adaptation of “torch-down” roofing, cold modified bitumen roofs eliminate the torch and use adhesives to ensure the membrane and the substrate are sufficiently bonded.

Monolithic Liquid-Applied Roofing blurs the line between roof coating and roof membrane system. Typically made of high-tech polymeric resins such as urethanes, these roofs are applied as a liquid and often need no reinforcing material, curing to a tough, rubber-like membrane. (See sidebar below).

Cautions

Naturally, as is the case with all roofing technologies, there are certain disadvantages to making use of cold-applied roof systems. Versus hot asphalt application, the cure time is much longer; Smith notes that “upon application, a certain amount of time needs to elapse before enough solvent flashes to increase the adhesive’s internal strength sufficiently to resist blistering, wrinkling, and other issues to the top substrate.” Martucci notes that the time to fully cure may take weeks.

Liquid-Applied Roofing is applied as a liquid and often needs no reinforcing material, curing to a tough, rubber-like membrane.

Additional considerations include the flammability of cold-applied adhesives that are made with solvated asphalt, as well as the potential for solvent odor to permeate through occupied spaces via vents, just as with the odors from hot-applied roof systems. Furthermore, cold-applied adhesives are typically more expensive than hot-applied adhesives.

Cold-applied adhesives may not be the optimal choice in all situations. Although some manufacturers will use these technologies with APP membranes, Martucci advises that these cold-applied adhesives may not be as effective in adhering the APP. He also recommends that caution be exercised using a cold-applied adhesive to attach a smooth-backed TPO or PVC, as they have lower adhesion values. This adhesion may also be a factor in high-wind areas, as cold-applied roof systems typically have lower wind uplift values than hot asphalt applications.

Kelly Franklin is industry affairs manager for the Roof Coatings Manufacturers Association (RCMA).

Liquid Applied Membranes

While the phrase “cold-applied roofing” originally described solvent-based built-up roofing (BUR), the term today has a significantly broader meaning, and includes liquid-applied membranes. These elastomeric roof coatings were first developed in the mid-1970s and are based on rubbers, acrylics, acrylic emulsions, and/or polyurethanes.

Unlike the cold-process described in the main article, liquid roofing (sometimes called “fluid-applied roofing,” involves applying a liquid-based coating to a roof, which cures to form a rubber-like elastomeric waterproof membrane. This coating can be reinforced with secondary materials to provide additional tensile strength, but the reinforcing material is usually a single layer, unlike BUR.

Because these membranes are applied as a liquid, they’re monolithic (no seams) and are typically considered self-flashing. The lifespan varies, depending on conditions and materials, but is typically about 25 years.

Liquid roofing is especially cost-effective as a repair technique; one British trade association calculates that it’s 70% less expensive than overall roof replacement.

It is ideal for roof restoration and is an excellent choice for roofs with difficult flashing details. When the roof of Whirlpool Corporation’s world headquarters building in Benton Harbor, Michigan, approached the end of its service life, the property manager turned to liquid roofing. While the EPDM roof was sound, it was out of warranty and nearing the end of its expected life-cycle. “An EPDM roof typically has a 10- to 15-year lifespan, and this roof was already more than 10 years old,” says Jeremy Brunan, a Michigan-based representative of the Garland Company, which performed the roof inspection. “The goal was to preserve and extend the life of the roof. Another priority was to reduce costs for cooling the building.”

He recommended topping the existing membrane with Garland’s White-Knight, a premium urethane waterproofing compound that also imparts a highly reflective surface. A Garland-approved contractor completed the restoration in just over a week, with no interruption to activities at the busy office campus. “Because [it’s] is fluid-applied, installation is quick, easy, and non-destructive,” explains Brunan. “Another advantage of the fluid-applied membrane is that it has no lap seams, which are the weak areas on a typical roof.” He says the restoration was half the cost of a new roof, and it’s now covered by a 10-year warranty.

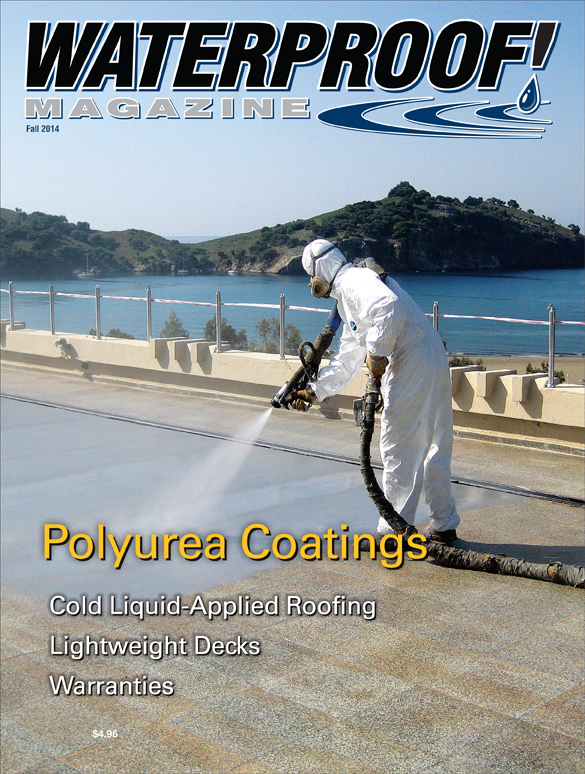

Fall 2014 Back Issue

$4.95

Apples To Apples – Comparing Waterproofing Warranties

Polyurea Coatings: The Basics

Cold Liquid-Applied Roofing By Kelly Franklin

Moisture And Lightweight Decks

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Apples To Apples – Comparing Waterproofing Warranties

Manufacturer warranties can be confusing, and often focus on the length of coverage instead of the terms. Here’s what a good warranty should cover as well as the limits of liability.

Polyurea Coatings: The Basics

Developed in the 1990s for the automotive industry, this technology has skyrocketed in popularity due to its fast-curing, corrosion- and abrasion-resistant characteristics.

Cold Liquid-Applied Roofing By Kelly Franklin

New technology allows built-up roofing to be applied without hot tar kettles, open flames, or noxious odors. A few are self-flashing and require no reinforcing mesh.

Moisture And Lightweight Decks

An increasing number of residential projects involve walkable roof decks. Careful design and detailing are crucial to ensure that they remain waterproof.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|