By Vanessa Salvia

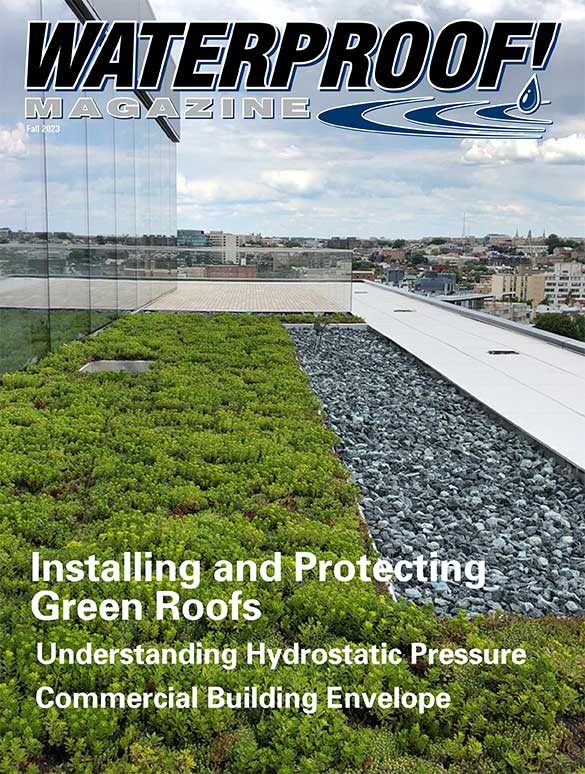

Photos courtesy of American Hydrotech

Whether you call them green roofs, vegetated roofs, or rooftop gardens, they have become increasingly popular in recent years as an eco-friendly way to add aesthetic appeal and environmental benefits to buildings.

A green roof is a layer of vegetation over supporting components that are installed on top of a flat or sloped roof. The benefits of green roofs include absorbing rainwater for stormwater management, providing insulation, creating wildlife habitat, and reducing a building’s carbon footprint. However, successfully installing and maintaining a green roof requires careful planning and protection to ensure the plants thrive.

Caroline Showers, a product manager for Tremco Roofing and Building Maintenance, says it pays to learn how to install and maintain green roofs because many municipalities are starting to require that builders manage heat islands and other effects of city life. “Green roofs help manage water runoff and they help with heat that comes off of buildings,” Showers says. “It’s also appealing to neighboring buildings because instead of having a view of a blank white roof with AC systems, you now might have a view of a vegetative roof, which is a much more appealing thing to look at.”

Types of Green Roofs

There are two main types of green roofs: extensive and intensive. Extensive green roofs have a shallow layer of lightweight growing media, 3 to 6 inches thick, that supports drought-resistant plants like sedums, grasses, perennial plants, and wildflowers. They require little maintenance and are the most common type of green roof. Intensive green roofs have a deeper growing media layer, 6 to 24 inches, that can support a wider variety of plants, including shrubs and small trees. They are heavier and require more maintenance but allow for a more diverse landscape. The type of green roof best suited for a particular building depends on several factors like roof load capacity, climate, budget, and how much maintenance can be provided. Some green roofs incorporate features like walkways, benches, and rainwater collection systems.

Materials for a Green Roof

Green roofs can be installed on new construction, which is most common, or retrofitted onto existing buildings. The roof deck must be engineered to be sturdy enough to hold the weight of the overlaid materials and vegetation. In general, green roof assembly includes a waterproofing membrane, a drainage layer, a geotextile filter fabric, growing media, and the vegetative layer. A waterproofing system with root resistance based on the German Landscape Research, Development and Construction Society (FLL) standards eliminates the need for an additional layer of root barrier, saving on labor and materials for the project. The waterproofing layer protects the roof from leaks and is often made of PVC or EPDM or a HRA (hot applied, rubberized asphalt). The drainage layer is often a geocomposite panel or sheet drain, ensuring excess water (not used in the green roof system) can make it to the drain unobstructed. The geotextile filter layer protects the drainage layer by preventing fine particles from eroding into and eventually clogging drains. Working with a manufacturer that supplies both the waterproofing systems and all of the other green roof components can make a single-source warranty covering overburden removal in the case of leaks possible for the building owner.

Some green roofs incorporate rigid pavers with adjustable pedestals adjacent to the vegetation layer to create walking paths, patios, or terraced landscapes. The adjustable pedestals allow for precise alignment of the pavers to final grade.

Green roofs can be designed to include water management strategies, which are often called blue roofs. Blue roofs can be created by providing a space within the assembly to temporarily detain rainwater. This can be done with pavers on pedestals or with box-like components that allow for green root components to be installed above the blue roof. The pavers provide a stable, elevated surface for people and they allow for foot traffic without damaging the waterproofing membrane or crushing the plants. Pavers provide critical access to rooftop elements including parapets and HVAC equipment.

Tremco sells pavers and pedestal paver accessories. “A green roof can also be walkable, with pathways, benches, and other features, or it can be half vegetated roof and half patio,” says Showers. “They can be very versatile.”

Waterproofing For a Green Roof

Richard Hayden is the retired national Garden Roof and Blue Roof Department Manager for American Hydrotech Inc. and an advisor with the Chicago-based manufacturer and distributor of waterproofing and roofing products.

Hayden says that the most important part of any green roof is the waterproofing, so to that end, anyone involved in the selection of materials for a green roof should select waterproofing materials and assemblies that have a proven track record of performance over many years.

“Waterproofing assemblies should be suitable for the wet conditions that are in every green roof assembly,” says Hayden. “In addition, an assembly that is designed to protect the membrane is ideal in green roof applications. This protection is most often provided by the thermal insulation in the assembly. By placing the thermal insulation above the membrane, the membrane is protected from thermal extremes, mechanical, and environmental damage during and after the installation of the green roof components.” Hayden calls these “protected membrane roof” (PMR) assemblies, and notes that they require a water-resistant insulation. “Extruded polystyrene insulation (XPS) is ideal for this application as it is not affected by the wet conditions present in green roof assemblies,” says Hayden. Proper protection means that your roof could never require replacement over the life of the structure.

Proper Slope and Drainage

There are some materials, such as hot-applied, rubberized asphalt waterproofing, which have proven performance in zero-slope roofs decks. But some membrane assemblies require slope. A flat roof design has advantages in metropolitan areas where height restrictions would mean sloped roofs might not be possible.

“Even in a zero-slope roof deck, water will eventually make its way to the drains,” says Hayden. “The physics created by the head pressure generated by the layers of insulation in a protected membrane roof assembly is enough to move water by gravity to the drains. This argues for a waterproofing membrane that does not mind being wet during this drainage process.”

Root Barrier Systems

“For common green roof plants like sedums, a simple plastic sheeting is often employed,” says Hayden. “Often this is a 10 mil polyethylene sheeting that is overlapped in accordance with the green roof manufacturer’s recommendations. In some instances, this sheeting may need to be heat welded.”

For aggressive roots, a heavier-duty sheeting of 30 mils, also overlapped, can provide a more significant barrier. “Some waterproofing assemblies incorporate specially treated protection sheets that are embedded into the underlying hot applied-rubberized asphalt membrane,” says Hayden. “These protection sheets incorporate copper hydroxide that deters more aggressive roots from venturing into the waterproofing assembly.”

When selecting root barriers, look for materials that have successfully completed a standard for root barrier testing.

This 267,000 sq. ft. extensive garden roof assembly in Englewood, New Jersey, used architectural pavers

and wood tile.

Drainage Layer Thickness

“The thickness of the drainage layer is generally related to the overall thickness of the growing media and can vary from a 10 mm-thick drainage layer for a thin green roof to 50 mm for deeper, intensive green roof assemblies,” says Hayden.

Filter Fabric

The filter fabric is a layer that sits between the drainage layer and the growing media. “This component is important in keeping the growing media out of the drainage component,” says Hayden. It can be part of the drainage layer component or it can be its own separate component.

Calculating Weight Per Square Foot

Green roof growing media is designed to hold large amounts of water while having high air space capacity. Some growing media can have a 50% water-holding capacity, and this weight must be part of the calculations. “A reasonable rule-of-thumb is that a green roof growing media can weigh 7 to 8 pounds per inch per square foot,” says Hayden. “Adding underlying components such as drainage layers, insulation, and the waterproofing assembly would increase that figure. Well-established green roof material and assembly suppliers will have specific test data available for use by architects and designers when evaluating building structural systems.”

Inspection and Maintenance

Green roofs do require some maintenance to be sure that the plants are performing at optimum levels. Generally, this timing will vary depending on the assembly used. “Spring inspections can help identify any issues that might have occurred over the winter,” says Hayden. Check irrigation and drains, and check any adjacent materials for damage or other issues. Summer maintenance can depend on the amount of rainfall the site gets and the amount of weeds that become established in the roof. Many plants go dormant in the fall, so that is a good time to clear leaves, inspect drains, and make sure the materials are prepped for any freezing that is to come. The fall season may also mean that irrigation can be shut down. Winter can bring storms. “Rooftops should always be reviewed after storm events for any issues,” says Hayden.

The Bottom Line

Installing and maintaining a successful green roof requires periodic inspection and some seasonal maintenance, but overall are low-maintenance when designed with quality materials. With the right waterproofing membrane, drainage system, growing medium, and climate-appropriate vegetation, green roofs can provide ecological and aesthetic benefits for many years. As more cities encourage green infrastructure to manage stormwater and reduce urban heat, green roofs present an opportunity to make commercial and residential buildings more sustainable. With proper construction and care, installing a green roof can be a rewarding way to add natural beauty while benefiting the environment.

Fall 2023 Back Issue

$4.95 – $5.95

AI in the Waterproofing Industry

Case Study: Northwestern University’s Simpson Querrey Biomedical Research Center

Installing and Protecting Green Roofs

Protecting the Commercial Building Envelope

Understanding Hydrostatic Pressure

Employer Responsibilities To Employees and Law

By Gregory Fahrenbruch

Description

Description

AI in the Waterproofing Industry

By Vanessa Salvia

It may be something you have to get used to, but once you do, it could be extremely useful and valuable.

Case Study: Northwestern University’s Simpson Querrey Biomedical Research Center

By American Hydrotech

The building’s proximity to Lake Michigan creates a high water table issue for the building.

Installing and Protecting Green Roofs

By Vanessa Salvia

There are many benefits of green roofs. However, successfully installing and maintaining a green roof requires careful planning and protection to ensure the plants thrive.

Protecting the Commercial Building Envelope

By Vanessa Salvia

Envelope performance directly impacts occupant comfort, health, energy efficiency, durability, and operating costs.

Understanding Hydrostatic Pressure

By Vanessa Salvia

When water accumulates and cannot drain properly, hydrostatic pressure builds up and pushes against the waterproofing membrane or material.

Employer Responsibilities To Employees and Law

By Gregory Fahrenbruch

Employers responsible for asbestos-related issues differ from those who do not work with asbestos but may have a potential for exposure to those who work abating asbestos products.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |