By Ryan McCoy

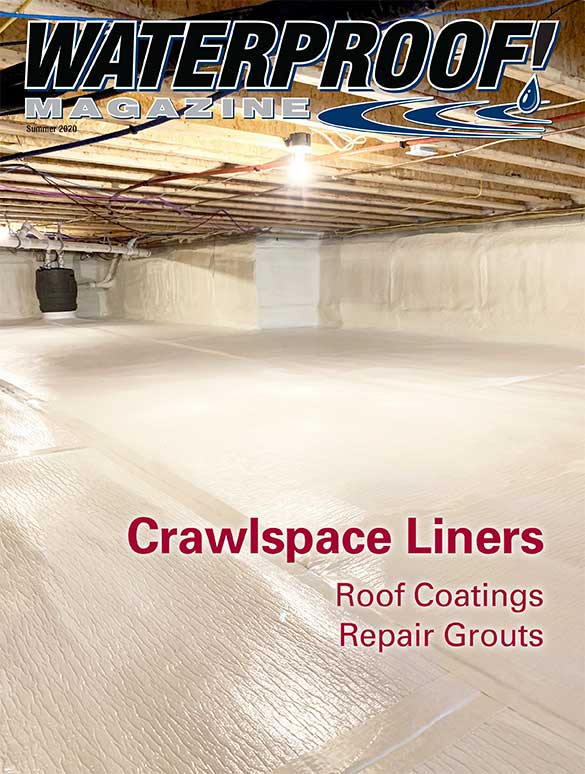

A typical crawlspace liner installation by Central Illinois Insulation

Humidity levels inside an unsealed or poorly encapsulated crawlspace are often higher than anywhere else in the home.

Moisture can come from several different sources, including exposed soil, wall vents and through the foundation via capillary action. When the dew point is reached inside the crawlspace, surfaces such as ductwork and floor joists are prone to condensation. If this happens repeatedly, the crawlspace can become a breeding ground mold, mildew, wood rot and pest infestation.

Standard six-mil polyethylene sheeting is inexpensive—and consequently a commonly used—material for covering dirt or gravel on a crawlspace floor. Unfortunately, these materials are often made with regrind or recycled content which can break down over time. They are also highly susceptible to tears and punctures both during and after installation. Once the integrity of the polyethylene is compromised, the crawlspace becomes vulnerable to moisture related issues.

Virgin Resin

Regrind or recycled resin reduces material cost, but also affects the resilience of the membrane. For experienced contractors, removing and disposing of deteriorated poly is an all too familiar part of their encapsulation projects. Fortunately, there are a number of crawlspace liner products available which are made with virgin resin. This choice drastically increases the resilience and overall performance of the final polyethylene sheeting.

Reinforcement

Crawlspaces often house mechanical equipment, or need to be accessed for pest control. Frequently, they are converted into extra storage for the homeowner. In each case, the crawlspace liner experiences heavy foot traffic. In order to ensure durability against this potential damage, many manufacturers add reinforcement to create higher tear and puncture resistance.

For example ISI Building Products uses large textile looms to weave individual strands of polyethylene together, which are then extrusion coated on both sides. This process creates a product with superior performance in the critical categories of puncture resistance, tensile strength and water vapor permeance.

More Than Mil Thickness

The unfortunate, but all too common evaluation of vapor barriers in the past has been centered around mil thickness. There has been an assumption that the greater the thickness, the higher the performance. This simply isn’t the case given all the variations of raw materials and manufacturing methods. A virgin resin, co-extruded 10-mil product will usually outperform a 12-mil single layer film made of recycled or reground resin. When evaluating vapor barriers, the emphasis should be on the specific performance characteristics and third-party test data, not mil thickness.

Jeremy Reets, owner of Reets Drying Academy agrees. “Often contractors equate quality to mils of thickness. This has not proven to be the best measure of quality in our experience. Our crawlspace is a working space with a gravel base layer. Approximately 700 students a year work on top of the liners in our crawlspace for training. This brutal environment will destroy the thickest of crawlspace liners. Surprisingly the Viper CS liners—which are thinner than the string reinforced liners we have used—have held up better than any reinforced liner we have ever used. These products are a game changer for encapsulation contractors.”

Training and Support

Professional contractors know having a skilled workforce is a critical component to success. In order for the encapsulation to perform as designed, it needs both a high-performance liner and a great installation crew.

Successful projects require understanding the potential pitfalls, how to treat certain installation details, job quoting, and worker safety.

Contractors looking to add this service to their companies should partner with a manufacturer that offers comprehensive training and support for encapsulations.

Reets offers immersive hands-on training at his facility in Sharpsburg, Ga. Some Home Builders’ Associations (HBAs) have also begun offering classes, such as North Carolina Building Performance Association’s Crawl Space Encapsulation Specialist Training. ISI is committed to supporting these efforts to ensure high-quality installs become commonplace.

Field-Proven Results

For ISI, the real measure of performance comes not only from the laboratory but from the field. Ivan Juarez, owner of Newport, North Carolina-based Elite Spray Foam Systems recently completed a 1,850-sq.-ft crawlspace project using ISI’s Viper CSX.

Like ISI’s Viper CS and Insul-Barrier lines, Viper CSX is made with virgin materials to increase material longevity, and includes a woven, reinforced core that’s perfect for small, heavily trafficked places like crawlspaces. The bright white helps brighten spaces that are sometimes poorly lit.

“This customer said he wanted the best, and that’s what we did…We are very pleased with the way this project turned out.” said Juarez.

Perhaps most gratifying is solid feedback from satisfied homeowners. Adam Shenaut, from Morton, Illinois was looking for ways to better utilize his unsealed crawl space. Upon searching the internet for ideas, he discovered crawlspace encapsulation and called Central Illinois Insulation to install a liner. “Before, the crawlspace was dark and dingy. This really brightened and cleaned it up and I feel very comfortable using this space for storage now” reflected Shenaut.

Ryan McCoy is marketing manager at ISI Building Products, a customer-focused materials manufacturer. He can be reached through the company website www.isibp.com.

Summer 2020 Back Issue

$4.95

Grouts for Waterproofing and Structural Repair

The Crawlspace: Link to a Healthy Home

Waterproofing Your Crawlspace

High Performance Crawlspace Liners

Working In an Era of Covid

Elastomeric Coatings: Misconceptions, Myths, and Key Considerations

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Grouts for Waterproofing and Structural Repair

Grouts can repair leaking manholes and sinking foundations, being injected into or behind the failure to eliminate moisture or restore structural strength.

The Crawlspace: Link to a Healthy Home

By André Lacroix

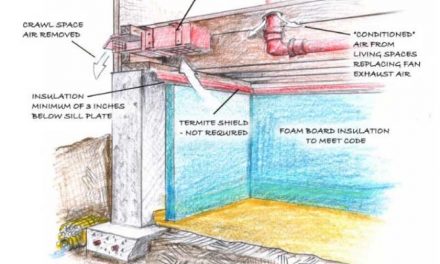

Encapsulating the crawlspace, conditioning it, and providing exhaust ventilation can create a healthy crawlspace.

Waterproofing Your Crawlspace

By Ben Rogers

Waterproofing, proper monitoring, and air quality control, can make crawlspaces a healthy, usable, and more pleasant area of the home.

High Performance Crawlspace Liners

By Ryan McCoy

High performance membranes can be used to encapsulate crawlspaces to improve air quality, energy bills, and the risk of mold and mildew.

Working In an Era of Covid

By Diana Parks

As the coronavirus spreads and threatens to derail construction projects, a legal expert explains how the industry can prepare for its effects.

Elastomeric Coatings: Misconceptions, Myths, and Key Considerations

By Chadwick Collins

Fluid-applied roof membranes made of high-tech resins cure to form a rubber-like elastomeric waterproof membrane that greatly prolongs the life of the roof.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|