Residential foundation repair is a growing and profitable opportunity for waterproofers. Solutions can include piering, grouting, crack injection and carbon fiber.

Many older homes are considered beautiful because of their character. It’s not unusual to see a house built in the early-to-mid 1900s with ceiling medallions, Dutch doors, crown molding, leaded glass windows and natural wood built-ins.

However, owning a house with these kinds of features can be expensive. For instance, electrical and plumbing might have to be updated to meet code. For many potential buyers, the biggest concern is the foundation.

Houses built a hundred years ago may be situated on a masonry foundation, rather than concrete. Or the soil may have subsided over the years to create structural foundation issues. Even homes constructed in the past few decades sometimes encounter this type of problem.

Troubling Signs

Kevin Kaufman, president at PierTech Systems, explains, “There are multiple signs that indicate a foundation may need to be repaired. Inside of the house, there may be cracks in the walls, ceilings or columns. Uneven, sunken, sloping or cracked floors or water damage are also signs of trouble.”

Another indicator is doors or windows that stick and don’t open or close easily. In the basement, the first sign is usually cracked or bowing basement walls, or water damage, which creates conditions for mold growth and can be hazardous to your health.

Slight changes in the foundation typically aren’t always a cause for alarm, but if the cracks are getting wider, longer, or increasing in number, the structure should be examined.

Causes of Movement

Kaufman says, “One of the most common causes of foundation movement is the shrinking and swelling of expansive soils. Soil expands when its moisture content increases and shrinks when the wetness decreases.” This swelling can cause CMU foundations to bow inward, or even lift the whole foundation upward.

Other causes of foundation movement include drying of soils around the house, improper backfill, tree roots, frost heaves, broken or cracked water pipes, waterlogged soil, and earthquakes.

Regardless of the cause of cracking, numerous repair options exist, including piering, grouting, crack injection, carbon fiber, and other methods. Many waterproofing contractors have found that adding structural repair to the list of services they offer has created opportunities for additional profit.

Underpinning

The first step is to determine if the crack is still moving, as the home must first be stabilized before the cracks can be addressed.

Piering can stabilize a weak or failing foundation, demonstrated here on a beachfront home in Massachusetts.

Underpinning—sometimes called piering—is usually the most economical option to deal with settlement issues. Basically, steel or concrete piers are driven or screwed into the soil, then attached to the house.

There are four types of piering commonly used by residential structural repair contractors: drilled piers, push piers, helical piers, and segmented concrete pilings.

Push piers use the weight of the structure to push the support beams into the ground to achieve stabilization. The pier is then capped off and permanently attached to the bottom of the foundation. The advantage of this method is that the contractor doesn’t need to know how deep to push the piers. When the weight of the house is insufficient to drive the piers deeper, that’s evident they can support the home.

Kaufman says, “These high-strength piers can be quickly and easily installed through unstable soil into load-bearing strata without the need for concrete. Not only is there minimal soil disruption, there’s also little disturbance to surrounding landscaping. Furthermore, push piers are able to be installed with lightweight, portable equipment when clearance issues prevent heavy-duty equipment from being used. Consequently, they are great for basement or crawl space foundation repair.

PierTech’s installation process begins by first excavating out to expose the structure’s footing. The footing is then notched about every five feet around the section of the structure that is settling. At each location, a bracket is anchored underneath the footing. Tubular steel push pier sections are then driven hydraulically into the ground next to the structure (using the weight of the building) until stable soil is reached. In addition to stabilizing a structure from further settlement, often times the foundation can then be lifted back to its original position.”

He continues, “Contractors, espec-ially those with small foundation repair companies, benefit from a fairly low-cost equipment investment. With a product that is less expensive per foot than others, they typically win more jobs. The investment in a push pier equipment package is less than $15,000. Plus, they don’t have to purchase any heavy equipment to complete foundation repairs.”

Earth Contact Products (ECP) offers push piers and helical piers. These are literally screwed into the ground. Mike Malina, marketing director at the company, says, “ECP helical piers are mechanically “drilled” through the shifting soil to a stable, load-bearing strata. After the installation has reached the specified depth and verified capacity, a steel foundation bracket is connected to the ECP helical pier and the home’s foundation. ECP’s helical piers come with an industry-leading 25-year warranty.”

ECP’s helical torque anchors were used to protect the foundation of a beachfront home in Massachusetts from scouring sand and wind uplift. The home sat on a grid of 12-inch diameter concrete foundation columns. The new system was designed to support a 30,000-lb. load even if eight to 10 feet of sand was displaced from below the structure. The solution was to drive 4-1/2-inch diameter helical anchors into the layer of cemented sand located approximately 20 feet below existing grade. Based on the torque required to reach this depth, the new foundation has an ultimate compressive capacity of 80,000 pounds, more than two and a half times the required strength.

Options for Bowed Walls

Many residential foundations, especially those made from cinder block (also known as CMU) suffer from bowed walls. When the bowing is less than two inches, carbon fiber is an attractive and effective solution.

Woven into sheets and impregnated with epoxy resin, it is extremely lightweight, yet ten times stronger than steel. Over the past 20 years, the product has been used to repair tens of thousands of basements. Luke Secrest, vice-president of sales at Rhino Carbon Fiber, claims, “Carbon fiber repairs are the fastest growing part of the foundation repair market ever.”

The product is available as straps, in sheets of various sizes, and also as carbon fiber staples. Sheets can be unidirectional or bidirectional, depending on the intended application.

The cracks are filled with grout or epoxy, and then the wall is carefully cleaned and the carbon fiber material adhered to the wall using epoxy. Once the epoxy has cured, the product can be painted or furred over. This is another major advantage of carbon fiber. It’s “thin as a dime” and requires zero maintenance.

Traditionally, when the bowing exceeds two inches, the only solution has been steel beams or wall anchors. While these still work well, new technologies have been developed in this area as well that are less invasive, less expensive, and less visible than ever before.

Carbon fiber is available as straps and sheets. It’s stronger than steel, and is virtually invisible once it’s painted.

For instance, a bracket exists that literally pushes the wall back into place without requiring adjustments from the homeowner.

Robert Thompson a professional engineer in Ohio and one of the inventors of the Force Bracket system, says, “We saw a growing need for a method to not only stop walls from bowing, but to push them back into place. We were having more and more cases where our certified installers could not use our Reinforcer carbon fiber strips because the bow in the wall was too large. Once an unreinforced CMU wall bows in more than about two inches, the eccentric load becomes too large for the carbon fiber system to work. We were determined to develop something that would structurally reinforce the wall and straighten it without requiring a person to frequently [tighten] a nut or bolt.”

The result is Nationwide Reinforcing’s “The Force” which will actually push bowed walls back into position.

A steel beam is secured against the wall. A bracket secures the bottom of the I-beam to the concrete slab with a pair of anchor bolts. A tension-loaded spring system anchors at the top. This powerful spring exerts a constant 1,000 pounds of lateral force against the wall that over time—without excavation or homeowner assistance—will push the wall back into its original position.

During hot, dry weather conditions the soil dries out, reducing its pressure, and shrinks away from walls. This is when The Force’s tension-load spring goes to work, physically straightening and structurally supporting the wall permanently.

For immediate results, a narrow trench can be dug on the outside of the wall, which allows the foundation to be pushed back into place the same day.

Once the wall has been straightened, it can be permanently reinforced and secured using carbon fiber. In addition to the Force, Nationwide Reinforcing also produces carbon fiber straps, four inches wide and the thickness of a dime; and The Reinforcer Shield, a unidirectional carbon fiber sheet intended for irregular shapes such as circular or square columns or interior basement wall corners.

Crack Injection

Low-pressure crack injection systems are the method of choice to repair cracks in poured foundation walls. They make it possible to repair and waterproof most foundation cracks from the inside using simple hand tools.

Today, both epoxy and poly-urethane resin are available in cartridge style systems that can be used with standard caulking guns or dual-cartridge dispensing tools. Both systems will effectively fill the crack while keeping water out. Epoxy will “weld” cracked concrete back together to restore the structural integrity of the concrete wall, and is a clear choice for repairs such as concrete that cracked during backfilling. Polyurethanes create a flexible seal, and are ideal for filling wider cracks and cracks that move based on seasonal changes. Epoxy is best installed in dry cracks while polyurethane resin systems are moisture reactive and may actually require the crack to be wet in order to activate the full expansion of the resin.

With either system, most basement repairs take less than one hour.

Pool Decks

In some cases, crack repair requires more than just an injection. Typically, if the epoxy fails, it’s not the injection that’s the problem, but rather concrete adjacent to it.

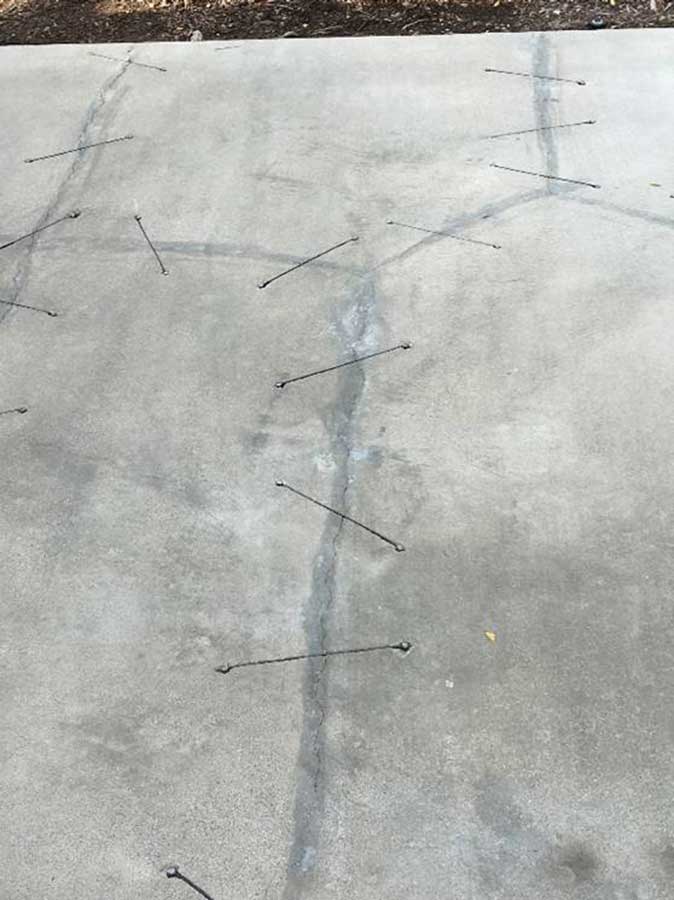

To stabilize cracks in pool decks and any other vertical or horizontal concrete, Rhino Carbon Fiber offers a dumbbell-shaped carbon fiber staple that makes crack repair faster, cleaner, and stronger than previously possible. Instead of relying on the strength of the injected material, the carbon fiber repair product locks directly into the concrete to carry the load.

Recently, American Restoration, a repair company based in San Francisco, California, was hired to repair a cracking concrete slab around a swimming pool. They had two concerns: first, they did not want this crack to re-open through their surface coating and second, they were worried about the possibility of the crack spreading.

They contacted Rhino Carbon Fiber, and after reviewing their options, determined the best solution would be to install Rhino’s Concrete Crack Lock stitches in conjunction with the company’s high strength anchoring epoxy paste to strengthen and stabilize the slab.

To install the Crack Lock, installers saw cut a thin slit in the concrete perpendicular to the crack and drill two small holes at each end. American Restoration created a plywood template to aid in the layout and installed the stitches every eight to 12 inches along the crack. These were anchored into place with epoxy and then the entire crack was injected and allowed to cure.

Finished with a protective coating, no evidence of the installation is present. The deck was successfully refurbished on a tight schedule.

Spring 2020 Back Issue

$4.95

Options for Structural Repair

Joints and Waterstops

Electronic Leak Detection

Case Study: Shoshone Power Plant

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Options for Structural Repair

Residential foundation repair is an urgent, growing, and profitable opportunity for waterproofers. Solutions can include piering, grouting, crack injection, and carbon fiber.

Joints and Waterstops

Available in a variety of profiles and materials, waterstops can play a major role in preventing water leakage at cold joints and expansion joints in concrete.

Electronic Leak Detection

New electronic leak detection methods can locate even the smallest leaks with pinpoint accuracy. Some systems can even monitor for leaks continuously with real-time alerts.

Case Study: Shoshone Power Plant

When a century-old hydroelectric plant deep in a Wyoming canyon was re-roofed, it included technology to ensure electronic leak detection even through the EPDM membrane.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|