Epoxy crack injection isn’t just for basements. A growing number of contractors have found a lucrative niche doing remedial and maintenance work on jobs that are measured in thousands of lineal feet.

Steve Geiger, national sales manager of the concrete restoration division at W. R. Meadows, says, “Below grade crack injection is usually done to address below-grade water leaks. Above grade work is done to address structural concerns in load-bearing concrete walls, columns etc. So urethane grouts, which work great to waterproof cracks in basements, usually aren’t suitable for above-grade work. It’s almost all done with epoxies.”

Much of the credit for developing above grade epoxy injection work goes to John Trout, now retired from Lily Corp., a maker of epoxies and injection system. Trout writes, “Epoxy injection has the reputation of being a structural repair procedure, and it is. However the vast majority of concrete crack injection applications (over 70% by the author’s reckoning) are structural preservation rather than repair. That is, [the technique is primarily used in] instances where resin is injected into faults in order to keep good concrete good rather than to restore design strengths. The sealing of cracks to protect exposed reinforcement is the most common example.”

Robert Trout, president of Lily Corp, says that above-grade structural epoxy injection is used worldwide on both horizontal and vertical surfaces. “We have a client in New Zealand who is injecting tens of thousands of lineal feet of cracks,” he says. “It’s all repair and stabilization work from the big earthquake.”

But crack injection is big business in the United States as well. A California general contractor recently completed an epoxy injection job on the San Francisco Bay Bridge. The scope of that maintenance work included injecting just less than 10,000 linear feet.”

Geiger explains, “That type of work is done to extend the life of the structure, it’s done to prevent corrosion from taking place and to prevent the crack from getting worse.”

Matt Stock, an owner at Illinois-based U.S. Waterproofing, confirms that the majority of crack injection work is maintenance. “We do a lot of basements,” he says, “but we do some above grade work; it’s almost all horizontal poured-in-place stuff.”

Materials Used

Because above-grade work is done to preserve or restore structural strength, this type of work requires a product that’s classified as a “structural epoxy.” ASTM C881 covers seven different types of epoxy bonding agents; Type 4 adhesives are most commonly used.

Geiger explains, “Type 1 and 4 are the load-bearing epoxies. Type 1 is for bonding new concrete to old, whereas Type four is formulated for bonding existing to existing. I’d estimate that 99% of crack injection jobs use a Type 4 adhesive.” (Epoxy types 2 and 5 are non-loadbearing, 3 is for flexible overlays, and types 6 and 7 are for bonding precast elements together.)

Geiger notes that ASTM C881 also grades epoxies on viscosity and temperature range, and that choosing the correct resin formulation is critical for jobsite success.

Typically, injectors use “ultra-low viscosity epoxies” that measure in the 500-900 centipoise (cP) range, which has about the same flow properties as motor oil.

Epoxies with viscosities as low as 300 cP are available, but typically lack the tensile properties required by ASTM standards. Geiger cautions, “Beware of brittleness. Pour a piece, and try and smash it the next day with a hammer. If it shatters, the crack repair will likely fail.”

Application

Despite the massive scale of some of these jobs, the application process is very similar to residential basement work.

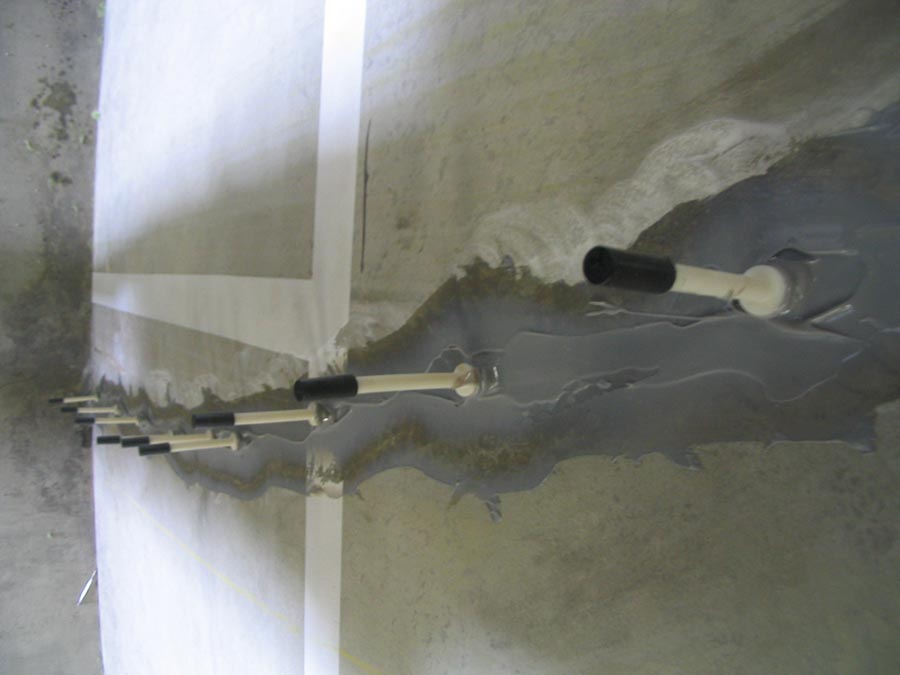

The first step is surface prep, mechanically cleaning the crack and surrounding surface with a wire brush or other abrasion tool. On above grade work, both sides of the crack are surface-sealed, so surface prep must be done on both sides as well.

“Surface prep is absolutely critical,” says Geiger. “When you’re injecting a column or shield wall, you’ll likely get into some pretty high pressures—it’s not uncommon to reach several hundred psi—so that bond must be absolutely tenacious.”

He continues, “Depending on the size of the crack—it’s width and length—you may not reach those pressures, but you never know until you’re injecting it.”

Both sides of the crack are face sealed. One is sealed entirely; on the other, it’s the typical combination of injection ports and sealing. Injection port placement is critical to ensure the crack is filled completely. (The standard rule of thumb is that the spacing of the ports can never be more than the thickness of the wall being injected.)

On commercial jobs, the quality of workmanship is nearly always tested by taking core samples. Stock, the Illinois contractor, says, “Bid documents typically specify that the epoxy fills 95% of the crack. They’re performance-based contracts, so if the work isn’t done right, you don’t get paid.”

Geiger says payment is usually on a sliding scale, and if the crack is not filled to at least 70%, the contractor won’t get paid at all. That’s because if the job isn’t done right, an engineer has to recalculate the loads to verify structural repair needs have been met.

Tricks of the Trade

Two types of injection equipment can be used for above grade structural crack injection work. One type mixes the resin and the catalyst at the nozzlehead, which gives the applicator more flexibility with his work schedule. The other type of equipment requires the applicator to premix the epoxy prior to injection.

“Make sure you can inject the whole batch before the pot sets,” cautions Geiger. Check the manufacturer’s pot life, and be aware that the figure was derived from testing on a small batch, so if you use a large quantity, actual pot life may be less than half of the stated time.”

Remember that it’s a chemical reaction, so the greater the mass, and the higher the temperature, the faster the epoxy sets. Every 15 degree (F) increase over 75 degrees will cut the the pot life by half.

Trout recommends inject during the cool hours of the day when cracks are at their widest. “Cracks open and close in response to daily changes in temperature; and due to alternating exposure to warming sunlight and cooling shade throughout the day. Though the amount of movement is very slight and the crack quite narrow, failure can occur when a high modulus epoxy capping material is applied over a crack and temperatures drop significantly.”

Summer 2012 Back Issue

$4.95

Worry-Free Sump Pumps

Crack Injection on Above-Grade Commercial Jobs

Green Roof Directory

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Worry-Free Sump Pumps

By Melissa Morton

The sump pump is the heart of the waterproofing system, so manufacturers do their best to create a long-lasting pump. But they also offer a variety of accessories to create a truly worry-free sump pump system.

Crack Injection on Above-Grade Commercial Jobs

Epoxy crack injection isn’t just for basements. A growing number of contractors have found a lucrative niche doing remedial and maintenance work on jobs that are measured in thousands of lineal feet.

Green Roof Directory

The print edition of the Greenroofs.com directory contains a comprehensive list of companies providing products for one of the fastest-growing roofing trends: vegetated roofs. Categorized by the products and services offered, this list is your go-to resource for green roofing expertise.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|