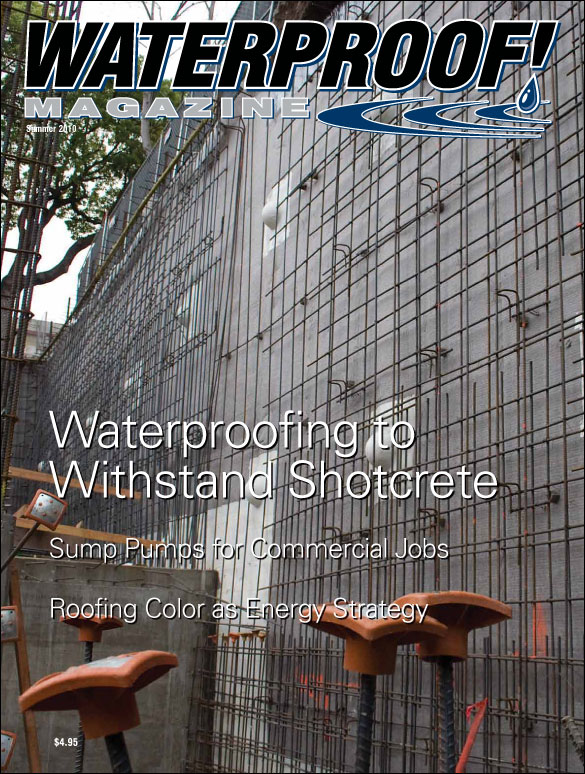

Getting a waterproofing and drainage layer tough enough to stand up to shotcrete is a top priority—because repairing the membrane after the fact is usually not an option.

Shotcrete, a method of applying concrete by shooting it out of a nozzle at high pressures, has now been in use for exactly 100 years. In the western United States, shotcrete is a popular choice for creating structural concrete walls in tunnels, retention ponds, deep foundations, and other blindside work. It’s also used to remediate failed concrete and masonry and even create structures such as water tanks.

Using shotcrete for constructing property line below-grade structural walls has become more common over the last ten years.

Shotcrete can be applied “wet,” that is, premixed in a hopper before being fed into the gun; or “dry,” where the cement-sand powder is mixed with water as it is propelled out the nozzle. Either way, shotcrete is typically cheaper, faster, and stronger than a comparable sized cast-in-place concrete project.

With either method, the concrete leaving the nozzle is pressurized to between 90 and 100 psi, so getting a waterproofing and drainage layer tough enough to stand up to the force of the shotcrete application is a major problem.

But dependable waterproofing is usually essential. It’s especially critical in blindside work because repairing the membrane after the fact is usually not an option.

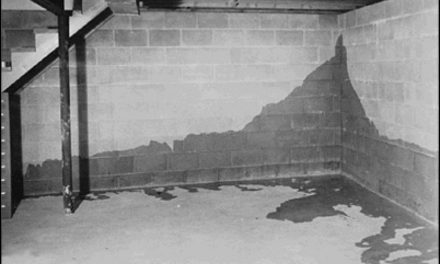

Because of its unique composition, shotcrete is especially prone to shrinkage cracks. Poor workmanship can create issues, such as voids between the shotcrete and the waterproofing membrane, or “shadow voids” behind steel reinforcement. Improperly mixed and/or porous shotcrete can also be a problem.

However, a number of manu-facturers have developed waterproofing solutions that can handle the unique challenges specific to shotcrete.

Durable Membranes

The most straightforward solution is to use a spray-applied coating or sheet good that’s tough enough to stand up to the application.

Dave Polk, owner of Epro Waterproofing Systems, encounters shotcrete often in blindside work, and says that a critical first step is to determine the type of soil retention that will be used. “There are four or five options on the type of soil retention system,” he says. These include soldier piles and lagging, probably the most common system. Other methods include soil nails, designed soil mixes, shotcrete soil stabilization and sheet piles. “Very rarely do you get conditions where you don’t have to put some kind of soil retention system in place,” he says.

Dave Polk, owner of Epro Waterproofing Systems, encounters shotcrete often in blindside work, and says that a critical first step is to determine the type of soil retention that will be used. “There are four or five options on the type of soil retention system,” he says. These include soldier piles and lagging, probably the most common system. Other methods include soil nails, designed soil mixes, shotcrete soil stabilization and sheet piles. “Very rarely do you get conditions where you don’t have to put some kind of soil retention system in place,” he says.

Polk bases his system around an extremely tough high-density polyethylene (HDPE) dimple sheet drain.

“The dimple board does a number of things,” Polk says. “First, the dimples reduce the force of the shotcrete’s impact. Second, the dimples provide a key to help keep the shotcrete from moving during placement. And lastly, those dimples keep the waterproofing and drainage layer bonded to the wall.”

First, the drainage layer is installed and fastened to the soil retention system. Polk says the overlap varies based on whether the backing is wood lagging or sheet piles. Once the drainage layer is installed and detailed, they spray on the waterproofing coating.

“This has two purposes,” Polk continues. “In addition to waterproofing the wall, it creates a better bond to the shotcrete.” Epro has conducted pull-off tests that reveal it takes between 42-50 pounds to separate the membrane from the cured shotcrete.

Self-Healing Sheets

A second option for waterproofing behind shotcrete is to use a self-healing bentonite membrane. Usually made from bentonite granules sandwiched between two geotextile sheets, this type of product stands up well to the rigors of shotcrete application.

Like the dimple sheets mentioned above, bentonite sheet goods are usually fairly easy to apply, once the prep work and detailing has been done. For example, the installation manual for Cetco’s Voltex states, “Simply position the product into place and fasten. Voltex DS can be installed on green concrete, in virtually any weather, without the need for primers or adhesives. Voltex DS can be easily cut on site to form around corners and penetrations.”

Like the dimple sheets mentioned above, bentonite sheet goods are usually fairly easy to apply, once the prep work and detailing has been done. For example, the installation manual for Cetco’s Voltex states, “Simply position the product into place and fasten. Voltex DS can be installed on green concrete, in virtually any weather, without the need for primers or adhesives. Voltex DS can be easily cut on site to form around corners and penetrations.”

Voltex DS is described as “a highly effective waterproofing membrane comprised of 1.10 pounds of sodium bentonite per sq. ft., two polypropylene geotextiles, and an integral polymeric liner bonded to the outside surface of the non-woven geotextile. The two geotextiles are interlocked by a proprietary needle punching process which encapsulates and confines the sodium bentonite.”

Paraseal LG, made by Tremco Commercial Sealants & Waterproofing, is another such option. It consists of a self-sealing, expandable layer of granular bentonite laminated to an impermeable, high density polyethylene (HDPE) sheet. The two-component system forms a tough, high performance membrane specifically designed for blindside applications. Applied with the bentonite facing the lagging wall, the HDPE is tough enough to withstand shotcrete applied directly to the face of the membrane.

Application Worries

Regardless of the membrane, however, proper preparation is crucial. Because of the force and weight of shotcrete, the lagging or retaining wall construction must be carefully inspected and detailed to ensure it can support the membrane.

The substrate must be solid, tight, and extend all the way to the bottom of the wall. Gaps larger than ½ inch must be filled or covered using an approved method. In high groundwater situations tying the vertical waterproofing in with the underslab barrier is a critical step.

The installation specs for Cetco’s Voltex, for instance, have this caution. “Specify that the wood lagging shoring is carried to the lowest level of the waterproofing installation. Require that the lagging boards be tight together and secure enough to receive the shotcrete application against the waterproofing system.” How much of a gap can these systems withstand? Grace’s Preprufe recommends “a sound and solid substrate [that is] regular and smooth with no gaps or voids greater than ½ inch.”

Larger voids can be filled with engineered soil or cementitious grout. Gaps in wood lagging are sometimes covered with plywood.

Polk, at Epro, claims, “It’s usually not the impact that’s the problem, but the shotcrete slumping on the wall. The key is that they [the nozzlemen] need to build it from the bottom, and not shoot too high on the wall.”

According to Polk, “The big bug-a-boo is that shotcrete cracks. There are almost always shrinkage cracks—not structural—so they’re not that big, but you need to ensure the waterproofing material is 100% bonded, so it will span them and kind of keep it stabilized.”

Post-Application Grouting

Using shotcrete to create structural walls requires a skilled nozzleman that knows how to ensure good consolidation and prevent voids.

Because this is not always the case, Grace Construction Products partnered with DeNeef Construction Chemicals to introduce a shotcrete waterproofing system that can handle some of the problems created by sub-par shotcrete.

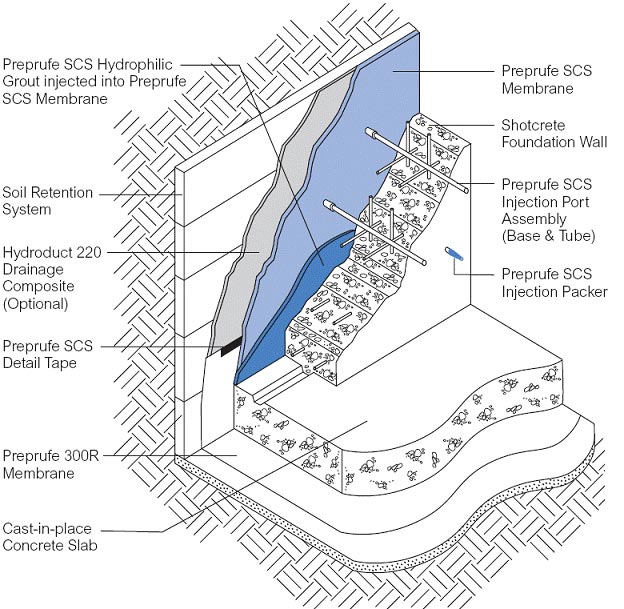

Called Preprufe SCS (for ShotCrete System), it allows for an expanding hydrophilic grout to be injected behind the wall after concrete placement.

Preprufe SCS from Grace Construction Products uses pre-applied injection ports to ensure any voids behind the wall are filled. In this photo, they’re the white domes visible behind the rebar.

“Chemical grouts have long been used to repair all types of foundation walls, including shotcrete,” says Craig Boucher, a product manager at Grace. “Remediation typically consists of drilling holes in the wall in the proximity of the leak and injecting chemical grout to fill the voids and seal the leak. This approach has been successful and is the most widely used method of repairing leaks in shotcrete foundation walls.”

“The challenge with this approach is that, until the repair is completed successfully, there is a risk of continual water damage, downtime of the structure, liability concerns, and other costly consequences,” he continues.

Once the waterproofing is in place, shotcrete is sprayed at pressures reaching 100 psi.

Brian Iske, president of DeNeef Construction Chemicals says it soon became clear “that injecting grout proactively into a pre-defined cavity space behind the shotcrete wall could be an efficient way to create a seamless water barrier.”

“The challenge,” he says, “was how to design and produce such a shotcrete-specific waterproofing system.

After three years of development and testing, the product is now available.

The system is installed in three steps.

- First, a sheet membrane is installed and attached to the lagging wall. It’s “designed specifically to withstand the force of shotcrete application and to control the thickness of post-injected grout.” The membrane consists of a plastic film (facing the lagging) and a nonwoven, semi-permeable geotextile (facing the shotcrete applicator).

- After the steel is in place, but before the shotcrete is applied, grout injection ports are installed-—usually every four feet on center—over the face of the wall.

- Finally, after the shotcrete has cured, a two-part hydrophilic grout is injected into the membrane through the injection ports. The grout fills the cavity created by the mesh layer in the membrane and escapes through the geotextile, filling any shotcrete voids. It also seals minor defects and cold joints, and can repair damage to the membrane caused by the installation of the reinforcing steel.

The result is a continuous waterproofing barrier, fully bonded with the shotcrete, that can withstand up to 200 ft. of hydrostatic pressure. The “envelope” between the membrane and the geotextile minimizes waste and ensures that the grout maintains a uniform thickness.

“Initially, we were not sure how the grout ports would affect the process of applying shotcrete,” says Larry Totten, President of Johnson Western Gunite Company of San Leandro, Calif., shotcrete contractor on one of the first Preprufe SCS projects. “As it turned out, the system did not impact our process in any way, shape, or form.”

Like all of the solutions mentioned so far, Preprufe SCS requires a solid backing behind the membrane. Grace specifies that the backing must be smooth, with no gaps larger than ½ inch. Otherwise, they recommend sheathing problem areas in ½-inch plywood or other facing materials approved by Grace.

Integral Admixtures

An easier, less labor intensive solution involves no membranes at all. A number of integral waterproofing admixtures have been formulated that waterproof the shotcrete itself.

“We traditionally recommended spraying Penetron onto the shotcrete surface,” says Ann Martucci, at ICS Penetron, which makes an integral waterproofing product. “While this is very efficient, it is also labor intensive and hence expensive. In recent years, a better solution was found; using Penetron Admix Enhanced Shotcrete.”

Introduced in 2005 and abbreviated PAES, the product has already accumulated an enviable record. Tests indicate that in addition to making the concrete impervious to moisture, it also improves its adhesion and freeze/thaw resistance.

How well does it resist moisture? One 2008 test involved taking two 50 gallon steel drums, drilling them full of holes, and then coating them with shotcrete. One used a regular mix design; the other used the Penetron Admix. After five days of curing, the drums were filled with water and pressurized to two bars. Fifteen days later, a visual evaluation showed that the PAES-coated drum was about 70% dry, whereas the control shotcrete was completely soaked with water.

Lab tests confirm that PAES reduced water penetration from 21mm in the control concrete to 7mm.

Field results are equally impressive. In the last few years it has been used to seal miles of aging rail tunnels in Scandinavia and Italy. It’s also being used on a massive potable water tank—70 ft. high and 140 ft. in diameter—being built using shotcrete technology in Harrisonburg, Va.

Conclusions

Shotcrete, already a century old, is a proven technology used around the world. While it presents unique difficulties to the waterproofing contractor, solutions do exist. Whether it’s an established product or a newer development, plenty of options exist to ensure shotcrete walls keep moisture out.

Case Study: Baltimore Hilton Convention Center

The Hilton Hotel in Baltimore Maryland is one of the newest additions to the city’s skyline. The 752-room hotel opened in August 2008, and was “designed to impress and accommodate every need of today’s traveler.”

Construction of the massive below-grade portions of the project were to be created with shotcrete, and presented some significant challenges, as the site has a high water table. Additionally, the project was built directly adjacent to the existing Baltimore Convention Center, which mandated a tight excavation footprint.

Brisk Waterproofing was selected to apply the 100,000 sq. ft. of below grade waterproofing membrane.

“The material we used was Cetco’s Volclay Ultraseal SP,” says Kevin Chorba, a manager at the company. He says they selected the bentonite sheet material “due to its ability to withstand shotcrete without tearing or the seams pulling apart.” It was mechanically fastened to the wood lagging with washers and staples.

“The tiebacks were covered with sheet metal boxes that we had gotten manufactured at a metal shop and detailing of penetrations was completed with bentoseal mastic,” Chorba continues. “The only concerns that we had with the application were dewatering of the site and keeping the seams from folding over.”

The results were impressive. So impressive, in fact, that the general contractor passed them the change orders for waterproofing the plaza deck as well. This effectively doubled the size of the original contract.

Summer 2010 Back Issue

$4.95

Water Barriers to Withstand Shotcrete

Sump Pumps for the Commercial Market

Black or White: Roofing Color as an Energy Strategy

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Water Barriers to Withstand Shotcrete

Shotcrete is a popular choice for tunnels, deep foundations, and other blindside work. But getting waterproofing that’s tough enough to stand up to the abuse is a top priority.

Sump Pumps for the Commercial Market

The larger volumes of water, higher head pressures, and complex dewatering systems involved in commercial work make selecting the right pump for the job more difficult.

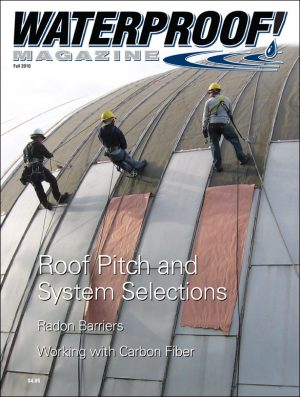

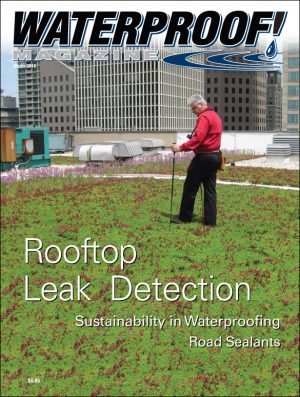

Black or White: Roofing Color as an Energy Strategy

While black roofing membranes usually do a great job keeping water out, they may also contribute to higher energy costs and the “urban heat island effect.” The solution may be a simple black-and-white decision.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|