by Clark Ricks

It’s a nightmare every homeowner dreads: The basement flooded, belongings soaked. Carpeting and drywall ruined and waterlogged.

While a comprehensive waterproofing and drainage system has many components, sump pumps are considered the most crucial. Unlike the membranes, drainage sheets, and perforated pipe, which usually last for the life of the structure, sump pumps need to be replaced every few years.

But waiting for failure isn’t an option, as it would inevitably lead to the nightmare described above.

But waiting for failure isn’t an option, as it would inevitably lead to the nightmare described above.

Fortunately, new pump technologies and proper installation can ensure that this critical piece of the system is fail-safe and affordable.

Components

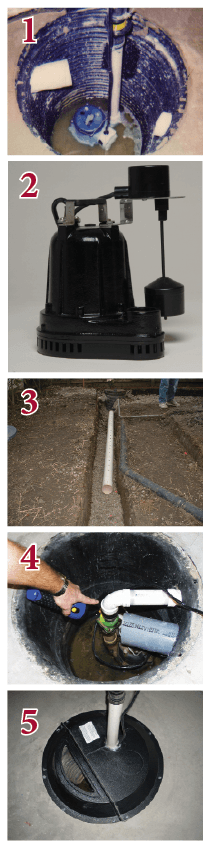

All sump pump systems have the same five components, although they vary in size based on the amount of water they are required to handle.

In the United States, components are fairly standardized. For residential applications, they consist of:

- A plastic or metal sump liner, either 18 or 24 inches in diameter and 2 to 3 feet deep.

- A pump, usually 1/3 or 1/2 horsepower and powered by either at 12-volt DC battery or standard 120-volt AC current.

- A discharge pipe, typically 1 ½ inch PVC.

- A check valve to ensure the water in the discharge pipe doesn’t flow backwards back into the sump;

- A cover to keep vermin, pets, and debris out of the sump.

Sizing

Pump Size: A properly sized pump is critical. Too small and it won’t be able to keep up with water flowing into the sump. Too large and it creates unnecessary expense. An oversized pump will also “short-cycle,” turning on and off in rapid succession, which leads to premature pump failure. So getting the right pump is an important first step to ensuring basements stay dry.

“It’s important that your pump can draw water out of the basin (or “sump pit”) faster than water flows into it,” notes Duane Friend, at the University of Illinois Extension Office. “Therefore, the first thing you need to measure is the amount of water that drains into the basin during a high-flow period. During a heavy rain, stick a ruler in the basin and measure how many inches of water flow into the basin in 60 seconds.”

With an 18-inch sump, each inch of depth equals one gallon. In a 24-inch-diameter basin, each inch is roughly 2 gallons.

In a new construction situation, approximate flow rates can be calculated based on rainfall averages, soil type and the size of a home’s footprint.

Once the volume of water that will need to be removed has been calculated, the installer will need to figure out the “total dynamic head” of the discharge pipe. This is the sum of the “static head” (the height in feet between the pump and the end of the discharge pipe) and the “friction head.” Friction head is calculated based on the length, diameter and material of the discharge pipe, and the number of turns involved. A table to calculate friction head is available on the www.waterproofmag.com website.

Knowing the maximum flow rate figures, the total dynamic head pressure involved, and the budget, the contractor or designer can determine the best pump for the application.

Basin Size: The size of the sump pit is also important, as it plays a part in how long the pump runs and how long it takes to fill up. If the basin fills too quickly it may be best to install a larger one.

If the basement is already finished, a cheaper option may be to raise the height of the pump switch, basically making the sump deeper. This method, however, also increases the chances the sump will overflow, so be careful.

The SmartHome sump pump (above) is a next-generation battery-operated sump pump. It is self-testing, self-diagnosing, and will immediate notify the homeowner by telephone and email if a component stops functioning.

Power Supply

Direct-Wired: Almost all sump pumps run on standard 120 volt AC current, but the pump must be supplied with its own line from the breaker box. It must also have a dedicated breaker. In most areas, the power supply must be installed by a licensed electrician unless the installer is also the homeowner. As always, check with local building codes and ordinances.

Pumps are usually hard wired into the electrical system, rather than plugged into a conventional outlet.

Battery-Powered: Sump pumps face their highest loads during thunderstorms, when rainwater pours into the sump pit from the foundation drainage system. Unfortunately, thunderstorms can also disrupt a home’s power supply, knocking the pump offline at the time it is needed most. That’s why some homes—especially those with finished basements—have a second battery-powered sump pump in case the first pump fails. In a few areas of the country, where the sump pit only fills occasionally, battery-operated pumps are used as the primary.

Setting up a battery-powered secondary pump involves purchasing and installing the following components in parallel with the others:

- A 12-volt DC sump pump matching the flow and discharge requirements of the primary pump.

- A 12-volt DC lead-acid battery. A typical automobile battery is adequate. Some use marine-grade deep cycle batteries which are more expensive, but lasts longer.

- A “trickle-charge” battery charger to keep the lead acid battery fully charged.

- A separate water level sensor, check valve, and other components. The discharge pipes usually connect downstream of the check valves.

“One of the problems with most backup sump systems is they are rarely used so a component failure will not be noticed and the system will fail to operate when needed,” says Friend.

A few battery-powered pump systems have an integral computer that tests the system periodically and sounds an alarm if something needs to be replaced—like a “check engine” light on a car.

Regardless, Friend recommends that backup systems be tested monthly. “A good time to test is just after a rain storm,” he says. “Pull the plug on the sump pump so the sump well fills and verify the backup system activates and empties the well.”

Water-Driven: Recently, a few manufacturers have begun offering sump pumps that use the home’s culinary water supply to power the pump. The pressure in the home’s main water line turns an impellor, which drives the pump. These devices eliminate the need for electricity entirely. They do cost more than motor-driven pumps, but because they don’t need a back-up pump, they can be cost-effective.

Regardless of the type of pump installed, plan on also using a simple battery-powered water alarm. The water sensor is attached to the sump liner a few inches below floor level and will sound a shrill alarm if the water level rises that high.

The discharge pipe (black pipe on right) should end as far from the house as possible. Here, it has been routed to a dry well, with perforated pipe and gravel to improve drainage.

Pump Type

Regardless of the type of power supply, sump pumps are generally divided into two classifications, pedestal and submersible.

Because pedestal pumps sit above floor level, they are usually hidden from sight in finished basements. This can be a purpose-built enclosure, as shown in the before-and-after photos above, or by building the sump in a closet or furnace room.

Pedestal pumps are mounted above the pit, where it is more easily serviced, but also more conspicuous. Submersible pumps sit inside the sump—usually near the bottom—and are completely immersed in the water.

The decision is usually based on whether the basement is finished, or will be, as the submersible pump is less obtrusive.

In commercial applications, submersible pumps are most common, as they funtion on a different principle. Unlike pedestal pumps that “suck” water up from the sump like soda thorugh a straw, submersible pumps “push” water up the pipe.

Discharge Pipe

The discharge pipe should end as far from the house as possible, to prevent the water from finding it’s way back under the foundation.

In decades past, the pipe was often connected to the sanitary sewer system. This practice is now outlawed as it can overwhelm the water treatment facilities. Be aware that if you are retrofitting an older home, codes and ordinances may require you to also reroute the discharge line.

Summer 2009 Back Issue

$4.95

Solar Roofs: Challenges and Waterproofing Solutions

Foam in Waterproofing Systems

Sump Pumps: Advances and Installation

Green Sealants at the Bottom of the World

AVAILABLE AS A PDF DOWNLOAD ONLY

Description

Description

Solar Roofs: Challenges and Waterproofing Solutions

The popularity of green building, coupled with significant price declines in photovoltaic systems, has led to a significant increase in solar roof installations. Here are solutions to ensure the roof is leak-free.

Foam in Waterproofing Systems

Whether used as a drainage board, underslab insulation, or in roofing systems, every waterproofer deals with foam board. Polystyrenes and polyurethanes each have their own advantages and special application techniques.

Sump Pumps: Advances and Installation

Sump pumps are a critical component of below-grade waterproofing in many areas of the country. New technologies and installation methods make them more fail-safe and affordable.

Green Sealants at the Bottom of the World

Princess Elisabeth Station was built in one of the world’s harshest and most remote regions. Designers also insisted on extremely demanding green building standards

Additional Info

Additional information

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

|---|