This massive 105-unit condo complex in Philadephia, Pa. used Rub-R-Wall, a water-based, spray applied membrane, to seal foundation walls reaching 23 feet high. It was covered with a dimple board for drainage and backfill protection.

The green building movement has raised expectations for waterproofing products. While green building certification has slowed, the shift towards eco-friendly solvents, easier recycling, and longer life cycles is expected to accelerate. Fortunately, products are available that meet green building guidelines while also speeding construction and imposing less health risk to the contractor.

Certification

Experts such as Jerry Yudelson, who has written 13 books on green building, say green building methods have gotten more popular, even though certifications have plateaued.

Yudelson says the current LEEDv4—which includes the requirement to report energy usage for the first five years of operation—is so burdensome that “many owners favor the ‘LEED certifiable’ approach that uses the LEED system for design guidance but do not to bother certifying.”

To back this claim, he cites data from 2012-2015, when LEEDv4 and its predecessor overlapped. More than 95% of the projects were certified under the cheaper and easier-to-understand LEED 2009. He says, “This does not bode well for the future of new project registrations, now that LEEDv4 is the only LEED system available for project registrations.”

Still, improving energy efficiency continues to be a major trend. Higher efficiency standards are being mandated in the new energy codes, and designers are scrambling to keep up. The latest report from the U.S. Green Building Council, published in February, says energy use has surged to the top of the green priority list. The trend for better air barriers above grade, and increased insulation throughout the building is affecting waterproofing.

Below Grade Efficiency

Below-grade residential water-proofers were on the front edge of this trend, as building codes have required continuous insulation for below-grade living space since the 2006 IRC updates. Frequently, this is installed as rigid foam boards on the exterior of the foundation.

Solvent-based waterproofing pro-ducts, however, are not compatible with foam. Manufacturers have responded by creating water-based coatings that provide the same level of protection the solvent ones do. They have several other advantages, as well.

Water-based coatings have no bad smell, and there’s no need for special ventilation. Splashes or droplets that fall directly on the skin are not harmful, and can be cleaned off with soapy water. There’s no need for special cleaning agents for the equipment or the jobsite, either. Overspray and spills can be cleaned up with water, if it’s done immediately after application.

Additionally, water-based coatings can be applied to substrates solvent based products cannot, such as damp or “green” concrete. This is a major advantage in situations where the concrete hasn’t fully cured, rain has fallen, or wet soil has been removed to expose a foundation that needs to be treated. This can create significant time savings—which often translates into improved profits for the waterproofer if schedules are tight.

Neptune Coatings makes one of these next-generation coatings. Their Wetsuit product is water-based, cold-applied, and VOC-free; yet it offers outstanding adhesion and “instant set.” More precisely, it’s 80% cured within three seconds of leaving the spray gun, allowing applicators to build up virtually any thickness in a single pass.

Other companies offer water-based waterproofing as well, such as W.R. Meadow’s Mel-Rol LM, and GMX’s UltraShield WB. All of these products are water-based, offer exceptional bonding, excellent elongation and handle thermal movement as well as minor cracking.

Rub-R-Wall, sold direct to contractors by Rubber Polymer Corp., is yet another example. The water-based version offers 1100% elongation with a tensile strength of 300 psi.

“This is a single-component system that contains no asphalt,” Matt Veazey, president and CEO at the company explains, “VOC’s are 15 grams per liter. Really, next to zero.” Je continues, “It uses premium ingredients like virgin rubber to ensure a high-end, high quality product. We feel confident that this product will offer protection well in excess of 100 years.”

It’s rain resistant in two hours and cures in 24 hours. Below grade, rigid foam boards and dimple drain sheets can be adhered simply by pressing them into the newly applied membrane.

Above grade, Veazey reports the product is popular as an air barrier, as the 100% rubber formula also makes the membrane self-healing if punctured.

The product was recently used on a massive 105-unit condo complex in Philadephia, Pa. Foundation walls reach 23 feet high. “It requires specialized skills to do walls that high,” Veazey says.

With products like these, general contractors can cut days from the schedule, and eliminate most weather-related delays. Waterproofing contractors can tighten their schedules and plan on doing more work in a given amount of time. Applicators will appreciate there’s no VOC’s, minimal odor, and easy to clean up. Yet the performance characteristics compare favorably with any other top-of-the-line coating.

Manufacturers of self-adhered membranes are also making their products greener and easier to apply.

Peel-and-stick membranes are a popular option for waterproofing in the ICF industry. ICF stands for insulated concrete form, a hollow stackable block made from rigid foam. Blocks are stacked into walls, which are then filled with steel-reinforced concrete. They’re growing in popularity, especially for green construction and insulated basements. Because the membrane must be applied to the foam, waterproofing is sometimes difficult.

To simplify the task, Protecto-Wrap recently developed a new, primer-free version of their self-adhered membrane. It adheres to most construction surfaces—OSB, plywood, concrete, CMU, foam insulation board, ICF and metal—without needing primer or mechanical fasteners. It eliminates the time and material associated with priming, and can be applied even when temperatures drop far below zero.

A primer-free peel-and-stick membrane was used to seal the ICF foundation of the state-of-the-art ProHOME.

Roofs

The movement towards sustain-ability is also affecting roof membranes. Yudelson predicts, “The roofing industry will continue to get greener with cool roofs and green roofs in both the residential and commercial sectors.”

Cool roofs, which are coated with a white or reflective surface can provide energy savings of up to 15%. Green roofs incorporating planted vegetation can double the roof membrane’s lifespan, add insulation, reduce storm runoff, and clean the air (see case study on p. 16)

Building sustainability experts understand that the vast majority of energy and water use is due to existing structures, and the drive to reduce these needs is moving to the forefront. The USGBC reports that in 2016, their LEED for Building Operations and Maintenance was by far the most popular of the LEED rating systems, representing 53% of the total square footage certified.

Roof membrane manufacturers are addressing this shift. Polyurea and silicone roof coatings, for instance, make it possible to extend the roof life by 10-20 years and save the cost, hassle, and waste of a complete reroof.

It’s also less disruptive for occupants, who can continue their normal day-to-day activities during restoration. Simultaneously, it reduces landfill waste and associated costs, and contributes to energy savings by meeting cool roof requirements.

Henry Company has developed a product line to address all four stages of the roof membrane life cycle: repair, restore, recover and replace. Lisa Santerian, senior marketing manager, says, “Not only do our restoration sys-tems provide a robust weatherproofing system for the roof, they also give the building owner and contractor access to additional resources and systems designed to maintain the roof throughout the life of the building.” Henry’s liquid-applied roofing systems are based on three separate technologies—silicone, acrylic and aluminum—to meet a wide range of environmental and structural needs.

Clean Air

One final trend affecting waterproofing is the move to eliminate volatile organic compounds (VOCs). The 2016 USGBC report cited above includes a headline claiming “Building Health Equals Human Health.”

Residential waterproofers have responded with a range of technologies to improve air quality in below-grade spaces. Dehumidifiers and Energy Recover Ventilators (ERVs) are usually cost effective solutions for basements. In crawlspaces, contractors are shifting to total encapsulation, venting radon and other soil gases outside before they enter the living space. Like the commercial installers, they’re also shifting to low-VOC products.

Cool roof coatings extend the life of the roof, lower energy costs, and save the expense, hassle, and waste of a complete reroof.

Crystalline waterproofing is one solution, possessing multiple green attributes in a single product. Lyda McClallen, at Kryton says, “Our product makes the concrete itself waterproof, so there’s no membrane to deal with. It adds durability and longevity to concrete by protecting it against chemical attack and corrosion of reinforcing steel. It reduces site disturbance and waste during construction, contains no VOCs, and is safe for use with potable water. At the end of the building life cycle, while membrane coated concrete goes straight to the landfill, Crystalline-coated concrete can be recycled post-demolition, eliminating waste and helping the project leave a lighter footprint.

The Future/Conclusion

As green building materials become the new industry standard, it favors contractors and designers that are familiar with the new and better products being developed by waterproofing manufacturers.

“If a contractor is spraying the same formulation he did 20 or 30 years ago, not only is he missing out on performance, but he’s missing out on the jobs he could be landing if he used more modern products,” says one expert. “These new materials not only keep the environment safer, but can provide better protection, faster cure times, and more durability than older products ever could.”

City Center in Las Vegas is the largest LEED-certified project in the world. It used crystalline waterproofing from Kryton for all below-grade concrete.

Summer 2017 Back Issue

$4.95

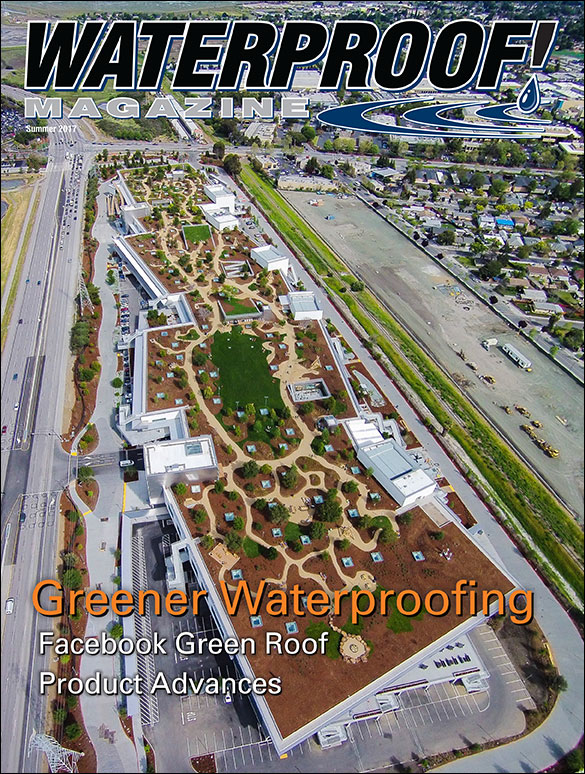

Light and Tight: Facebook Green Roof

By Michael McAuley

Advances in Commercial Waterproofing

Greening Your Waterproofing

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Light and Tight: Facebook Green Roof

By Michael McAuley

The flat roof on Facebook’s new headquarters has a garden roof the size of seven football fields, and includes a half-mile walking path that winds through more than 400 full-size trees.

Advances in Commercial Waterproofing

From deep foundations to rooftops, new waterproofing technologies are helping create structures that are better-performing and more cost-effective than ever before.

Greening Your Waterproofing

The green building movement has raised expectations for waterproofing products, with a shift towards more eco-friendly solvents, easier recycling, and entirely new types of waterproofing.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|