The new Voxman Music Building greets students when they return for the fall semester in August (artist rendering provided by the University of Iowa).

In June 2008, following a winter of heavier than normal snowpack and intense spring rainstorms, the Iowa River flooded parts of Iowa City, Iowa. It claimed several University of Iowa properties, including the venerable Voxman Music Building that was built near the western banks of the river. “Our community was torn asunder,” recalled music school director David Gier.

A decision was made to build a new facility on higher ground. The corner of Clinton and Burlington Streets was chosen as the new site, located about one-half mile east of the river and at a significantly higher elevation. In addition to housing the music school, it would also help anchor the southern side of a thriving downtown area, adding an important new relationship between the school and the city.

The new Voxman Music Building was completed just in time to greet students returning for Fall semester classes, with a formal opening ceremony scheduled for October 21. The 180,000-sq.-ft. facility is the new home for approximately 450 music majors, and features a mostly glass structure containing a 700-seat concert hall, 200-seat recital hall, an organ performance hall, opera and chamber music rehearsal spaces, faculty studios, classrooms and individual rehearsal spaces.

A self-adhering air/vapor and liquid membrane barrier was applied to all vertical and horizontal surfaces on the building.

Everyone understood the building had to have a building enclosure that would be effective against air, vapor and moisture. Besides the enclosure requirements, a whole host of geometrical issues also had to be dealt with.

Local architect Chucho Loria of Neumann Monson Architects said the technical requirements of the new Voxman Music Building would make it unique in terms of complexity.

“A huge percentage of the spaces are acoustically sensitive in that kind of music environment,” he says.

The university engaged LMN Architects from Seattle to be the lead design firm that would partner with Neumann Monson to form a team to manage the complex project. As part of the design team, envelope consultant W.J. Higgins knew W. R. Meadows had the air and vapor barrier products and support to achieve the goals set forth in the unique construction requirements, so that’s what they specified.

“I had worked with them before on multiple projects with good results,” recalled Loria.

Mel-Prime W/B, a water-based adhesive, was applied to surfaces requiring a self-adhesive air/vapor barrier. Air-Shield was installed on all vertical and horizontal surfaces. It is a sheet-good product, that is a self-adhering air/vapor and liquid moisture barrier. This membrane material has a controlled thickness of about 40 mils and is fabricated from cross-laminated polyethylene bonded to specially modified asphalt.

Pointing mastic was applied to seal all vertical and horizontal seams, resulting in an airtight waterproof envelope capable of protecting the valuable instruments, papers and the sounds produced within the School of Music.

Various areas of the building were designed with musical acoustics in mind.

A building project of this magnitude and complexity usually experiences unexpected problems during construction. Ryan Scrivner, foreman with Midwest Caulking, was in charge of installing the air and water vapor barrier. He noticed a problem with the exterior drywall’s ability to hold the primer. “We’ve worked with all kinds of different exterior sheathing, but this is the first one that it did not take to the primer,” Scrivner says. “We immediately called Jim Weatherly.” Weatherly is Meadows field rep for the region. Sure enough, he had seen the problem before with this particular product and recommended changing to a different formula, which resolved the problem.

Loria also appreciated the field support. “The university had some concerns about the UV exposure. Due to construction sequencing and project scheduling, the membrane needed to be left exposed to the elements longer than what we typically see in our projects.” Representatives from Meadows came and inspected the membrane, then wrote letters of certification that the membrane had suffered no damage from the UV exposure. “It was very helpful,” says Loria.

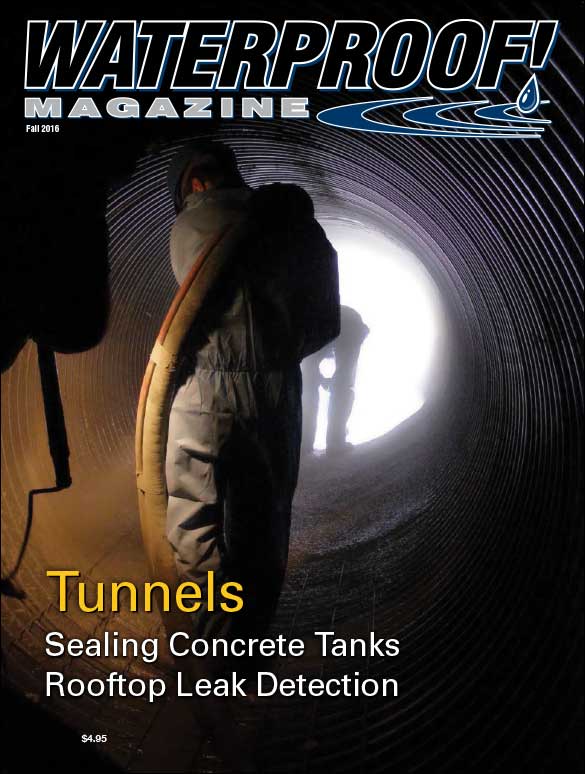

Fall 2016 Back Issue

$4.95

Solutions for Tunnel Waterproofing

Real-Time Automated Leak Detection

Sealing Commercial Concrete

Project Profile: Voxman Music Building

AVAILABLE AS DIGITAL DOWNLOAD ONLY

Description

Description

Solutions for Tunnel Waterproofing

The massive scale and hydrostatic pressure of tunnel projects require special waterproofing solutions, especially when groundwater is contaminated.

Real-Time Automated Leak Detection

New technology is available to monitor roof membrane performance in real-time. This is especially useful in ballasted and green roof applications.

Sealing Commercial Concrete

When a concrete tank 45 feet below the water table began leaking, the solution was as innovative as it was effective.

Project Profile: Voxman Music Building

Rebuilding from a massive 2008 flood, the University of Iowa rebuilt their music building to withstand moisture above and below grade.

Additional Info

Additional information

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |

|---|