By Clark Ricks

Frank Lloyd Wright called the tabernacle “one of the architectural masterpieces of the country and perhaps the world.”

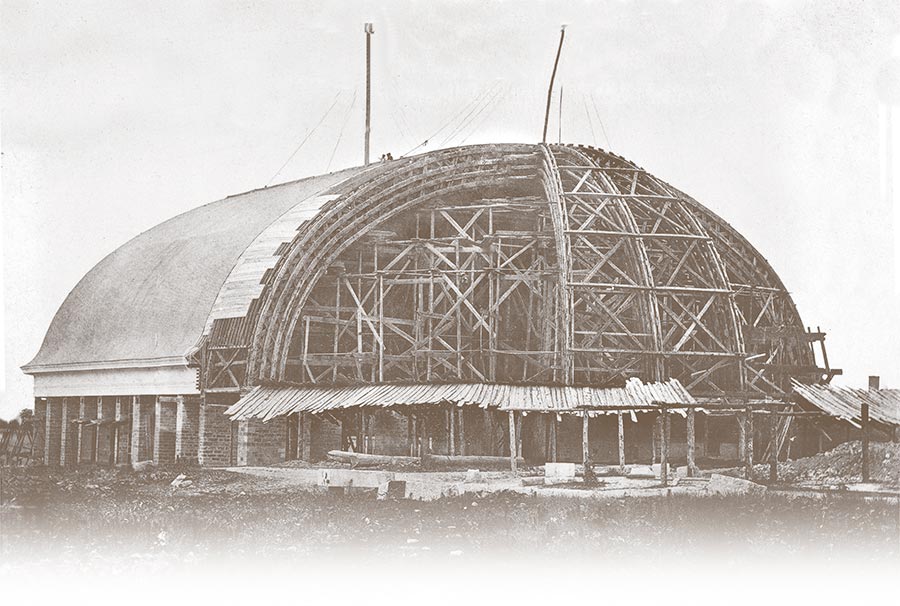

The Mormon Tabernacle in Salt Lake City is one of the most famous buildings in America. It’s also one of the most unique.

Measuring 150 feet wide by 250 feet long with an enormous dome shaped roof, early critics ridiculed it, describing it as a turtle that lost his way in the desert.

More knowledgeable designers, however, recognized it as a work of genius. Frank Lloyd Wright called the tabernacle “one of the architectural masterpieces of the country and perhaps the world.”

Now nearing 150 years old, the building was scheduled for a major renovation, including a new roof.

Built in the 1860s by pioneer members of the Church of Jesus Christ of Latter-day Saints, construction was an exercise in resourcefulness. Church leaders directed Henry Grow, who designed the structure, that the building needed to seat 10,000, with good acoustics and unobstructed views.

Using his bridge building experience, Grow designed a series of semicircular trusses that supported the roof without interior columns. The trusses were made from local timber, pegged together and strengthened with rawhide since iron was unavailable.

The trusses, placed on sandstone columns 20 feet apart, were tied together with rough-sawn 3 x 12 planking, which formed the roof deck.

“It’s really an engineering marvel,” renovation architect Roger Jackson of FFKR Architects said. “They built it to last and they built it the absolute best that they could.”

The meeting hall was the largest west of the Mississippi for more than 50 years, and has been recognized by the American Society of Civil Engineers as an engineering milestone. It was added to the National Register of Historic Places in 1970.

Shortly before the renovation began in 2005, current church president Gordon B. Hinckley said, “Buildings, like men, get old. They don’t last forever unless you look after them. I respect this building. I love this building… I want it preserved.”

“That was our charge,” says Jackson, “to do [the renovation] well and to keep this building so that it could be used.”

The Roof

One key aspect of preserving the historic structure was to install the best roof possible.

The original pine shingles, installed over the thick plank decking, were replaced with tin in the late 1800s. Shortly after the Second World War, the current aluminum panels were installed.

“The roof on the tabernacle is quite complex,” explains Jim Ritchie, vice president of estimating at Utah Tile and Roofing. Ritchie served as project manager on the re-roof job. “Because of the dome shape, the roof is dead flat on the top, sloping to nearly vertical on the sides. There’s a convex curve to most of it, but it’s concave near the gutter, and there are tapers on both ends.”

“Because of the dome shape, the roof is dead flat on the top, sloping to nearly vertical on the sides.”

“About a year before this project started, we took the roofing apart in one area down to the underlayment that was put down 12-15 years ago, and helped them look at several systems they could use,” says Ritchie.

Jim Morgan, a field rep at Grace Waterproofing, was involved with this earlier job. “The re-roof 15 years ago involved removing the aluminum panels and stripping everything down to the original plank decking, which had shrunk considerably” he says. “We installed a layer of our Grace Ice & Water Shield over the planks, repaired the aluminum panels, and put them back on.”

Grace was chosen again for the most recent job. ““They had quite a slew of underlayments choose from,” says Morgan, “but they chose Grace Ice and Water Shield both times because it seals better around the fastener than any other product. The metal roof panels are screwed down, and it’s difficult to seal on the threads. The owner actually had some nail sealability tests done, and Grace performed the best. It’s not surprising because we use the best rubberized asphalt formulation, and that creates the best seal around the fastener.”

Project Scope

The major aim of the most recent renovation was a seismic upgrade, which involved reinforcing the foundation and installing several steel “sister trusses” in the roof diaphragm next to the original wooden ones. The owners also decided to replace the roof, since it had to be partially dismantled for the truss installation anyway. Utah Tile and Roofing got the job.

“Basically, the first part of the job was to remove the roofing panels that had been on for 57 years, remove the felt underlayment in place for condensation, and install a temporary roof with wood battens and visqueen,” says Ritchie. The visqueen, along with the old Grace Ice & Water Shield would serve as temporary construction roof for the next phase of the job.

With the temporary roof in place, a hole was cut through the original plank decking to install the steel trusses. Each truss was disassembled and fit through the opening in nine separate sections to minimize damage to the roof diaphragm. During this period, the skylights and venting were also renovated. “It was under visqueen for several months, probably three or four,” says Ritchie.

Logistics

Logistics were a major challenge.

The Tabernacle is a central feature of the church’s Temple Square, Utah’s most-visited attraction. The square draws between 3 million and 5 million visitors annually—as many as the state’s five national parks combined—and the square was to remain open during construction. A sturdy construction fence was erected immediately around the building, and staffed with security guards. Workers had to have an access sticker on their hard hat to be allowed into the construction area.

“We were fairly fortunate in that we were pretty much the only trade on the roof,” says Ritchie. The site was too cramped to keep materials on site, but owners provided a storage yard about a block away.” Ritchie notes that even though the site was restricted and access was a challenge, Jacobsen Construction, the general contractor, did an outstanding job organizing schedules, construction phasing, and coordinating access between numerous diverse trades on site. “This was truly the miracle of the job,” he says.

With the trusses in place, Utah Tile and Roofing could begin putting the roof back together.

As each section was completed, workers removed the visqueen and battens, and installed a layer of ½” plywood. To meet structural requirements, the wood was applied diagonally, meeting on the ends in a herringbone pattern. Roofers then covered the plywood with another layer of Grace’s ice and water shield. Two layers were applied in areas with less than a 2:12 pitch.

“It’s a hard roof to begin with, and the logistics were terrible.” says Ritchie. “With Jacobsen digging holes in the ground [to reinforce the sandstone piers], we couldn’t get the man lift into some of the areas we’d wanted to.

Safety was a major concern. Jacobsen put up safety rails on the flat upper section, and workers inside the fence tied off to that. “Anything outside of that required full body restraints,” says Ritchie. “Everyone wore a full body harness. We used ropes and rock climbing gear for safety on the steeper portions, and used ascenders to get up and down the vertical pitches. We also were able reach quite a bit with the 40-foot articulated boom lift. We staged all the plywood from that; we never plywood stacked on the roof.”

The scope of work also involved rebuilding the gutters and installing new aluminum roof panels. “The panels had already been re-installed once with moderate damage, and the owner wanted to go to a heavier gauge,” says Ritchie. The new panels were made by the same company that made the original aluminum panels almost 60 years earlier.

The Result

The project, completed earlier this year, is already gaining attention, both for the quality of the renovation and for the challenges overcome.

The roofing portion of the job, which was one of the more difficult tasks, was completed so well that industry insiders speculate it may win a Gold Circle Award. Sponsored by the National Roofing Contractors Association (NRCA), contractors can vote at their show in Las Vegas next February.

Jackson, the restoration architect, says, “The building is an important part of the heritage and culture of the city, the church and the United States. It’s truly a one-of-a-kind treasure.”

Fall 2007 Back Issue

$4.95

This is the Very first issue of WATERPROOF! Magazine.

Blindside Waterproofing

Project Profile: Roofing a Historical Landmark

Footing and Drainage Boards

AVAILABLE AS A PDF DOWNLOAD ONLY

Description

Description

This is the Very first issue of WATERPROOF! Magazine.

Blindside Waterproofing

Occasionally, waterproofing and drainage membranes have to be applied before the below-grade structural wall is built. Here are the products and techniques the experts use.

Project Profile: Roofing a Historical Landmark

The 140-year-old Salt Lake Tabernacle needed a new roof. The challenge was that it is one of the most complex—and famous—roofs in the country. Having the congested jobsite right in the middle of Utah’s most visited tourist attraction added another degree of complexity.

Footing and Drainage Boards

The key to ensuring a good, waterproof basement depends as much on the drainage system as the waterproofing membrane itself. Drainage boards relieve hydrostatic pressure by directing water to the base of the structure. Footing drains remove that water away from the building.

Additional Info

Additional information

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

|---|