By Tom Stuewe, Senior Product Manager, Siplast

Photos courtesy of Siplast

In today’s fast-paced commercial construction landscape, polyurea and polyurethane-based deck coating systems have become indispensable for their exceptional combination of durability, flexibility, and performance. Designed to help protect surfaces against vehicular and pedestrian traffic and challenging environmental conditions, these advanced coatings offer a long-lasting solution for protecting vital structural elements.

Their technical advantages, including advanced durability and protection, make them a strategic investment for architects, contractors, and building owners looking to enhance both performance and lifecycle value.

Engineered to meet the demands of modern commercial buildings, these coatings are ideally suited for applications such as lower decks, intermediate parking garages, parking spaces, and for surfaces outside of trafficable areas, such as balconies.

Their ability to adapt to structural movement while maintaining a seamless, watertight barrier helps ensure long-term concrete protection and aesthetic integrity. As performance expectations and environmental standards continue to rise, polyurea and polyurethane-based systems offer a forward-thinking approach to protecting valuable structural assets and potentially reducing lifecycle maintenance costs.

Performance Characteristics

The technical benefits of polyurethane and polyurea-based solutions apply for a range of commercial building challenges. This is due to several characteristics, including protection against chemicals, abrasion, and ultraviolet (UV) stability.

Commercial buildings can encounter exposure to harsh chemicals, from automotive fluids in parking areas to cleaning agents in public spaces. What distinguishes a polyurea-based system is its remarkable ability to withstand prolonged contact with these substances without degradation, tested in accordance with ASTM E303. This resilience translates to reduced maintenance needs and extended lifespan for commercial structures.†

Some waterproofing membranes degrade when exposed to prolonged sunlight, which can lead to premature aging, cracking, and costly replacements.† Polyurethane- and polyurea-based systems, such as Siplast’s Terapro PUR, are formulated to withstand intense UV radiation without significant deterioration.

This UV resistance makes them ideal for exposed applications, including balconies, terraces, and walkways. When used in conjunction with epoxy primers, Terapro PUR can serve as a durable top coat, enhancing overall system performance and longevity in UV-exposed environments.

Areas experiencing high foot or vehicular traffic require exceptional durability from their protective coatings.† Poorly-manufactured materials can often lead to costly repairs, replacement, and downtime, making long-term durability essential.

This property makes it particularly beneficial for many exterior applications, including parking structures, high-traffic balconies, and more.

When applied to surfaces, the liquid, synthetic polymers of polyurethane-based deck coatings form a protective barrier, offering long-term protection against water and weathering. Furthermore, the inherent flexibility of the chemistry allows it to adhere to a variety of surfaces.

Polyurea and polyurethane-based products can be modified for a variety of surfacing and color finishes, contributing to the desired aesthetic of any project. Additionally, its skid resistance, in accordance with ASTM E303, helps maintain a clean finish.

Benefits for Industry Professionals

The technical sophistication of today’s building landscape requires professionals to navigate projects with efficiency and reliability. Consultants, for instance, must be knowledgeable and recommend materials with proven performance across multiple parameters. By recommending systems with demonstrated longevity and performance from trusted providers with a proven history, such as Siplast, consultants can enhance their professional reputation while delivering genuine value to their clients and reducing building disruption.

For building owners, polyurea and polyurethane-based deck coating systems offer an economic advantage with a high return on investment. The material’s extended service life and minimal maintenance requirements may potentially provide savings. It’s important to remember that the initial installation cost represents only a part of the true lifetime expense of waterproofing systems. Replacement, repair, and associated disruption often constitute the major expense over a building’s lifespan.

Meanwhile, architects may prioritize materials that balance durability and function with aesthetics. Terapro PUR’s versatility accommodates designers’ creative design solutions without compromising performance or waterproofing concrete protection.

Real-World Applications

To get a better idea of use cases, polyurea and polyurethane-based systems are ideal for commercial surfacing such as parking structures, rooftop decks, balconies, industrial facilities, and more.

Parking facilities present multiple challenges for waterproofing materials — constant vehicle movement, tire abrasion, exposure to automotive fluids, and often extreme temperature variations. Terapro PUR’s durability makes it exceptionally suited for these environments.

Outdoor amenity spaces, especially building rooftops, have grown increasingly popular for commercial buildings, providing tenants with outdoor environments for leisure or gatherings. These areas must withstand UV exposure, rain, challenging temperature extremes, and ongoing foot traffic while still maintaining an attractive appearance. Terapro PUR’s UV stability and weather resistance help preserve aesthetics and protect the underlying structure over time.

Balconies and other projecting elements face similar challenges as they are exposed to environmental stresses from multiple directions and must endure frequent foot traffic.† Terapro PUR’s protection against abrasion resistance and flexibility provides the necessary protection to withstand these elements.

Industrial facilities often present an even more challenging environment, combining heavy mechanical stress with exposure to aggressive chemicals. Terapro PUR’s protection against chemical and abrasion resistance helps provide lasting protection even under harsh manufacturing conditions.†

Conclusion

As construction technology and building expectations evolve, traffic coating solutions must advance to meet increasingly complex performance requirements. Polyurethane and polyurea-based deck coating systems offer a durable, versatile, and efficient solution for commercial building challenges. Their technical advantages make them a strategic choice for enhancing the performance and longevity of commercial structures.

By investing in these advanced coating systems, building owners can ensure their properties are well-protected and built to endure. This investment delivers immediate functional benefits while also supporting long-term savings and sustainability, making polyurea and polyurethane-based systems a smart choice for any commercial building project.

† Siplast warranties and guarantees do not provide coverage against exposure to chemicals, including vehicular fluids, or abrasion. Refer to www.siplast.com for more information on warranty and guarantee coverage and restrictions.

The opinions and views expressed do not necessarily represent those of Siplast. The content is for informational purposes only. It is not intended to constitute financial, accounting, tax, or legal advice, or professional design advice as to any particular project. In no event shall Siplast be held responsible or liable for errors or omissions in the content, or for the results, damages or losses caused by or in connection with the use of or reliance on the content.

Tom Stuewe

With more than 18 years of experience in the building industry, Tom Stuewe serves as the senior product manager at Siplast, a Standard Industries company that develops and manufactures sophisticated and highly engineered roofing and waterproofing systems. He helps to develop industry-leading roof membranes and liquid-applied systems, restoration coatings, low odor and low VOC membrane adhesives, and plaza deck systems for the commercial building envelope.

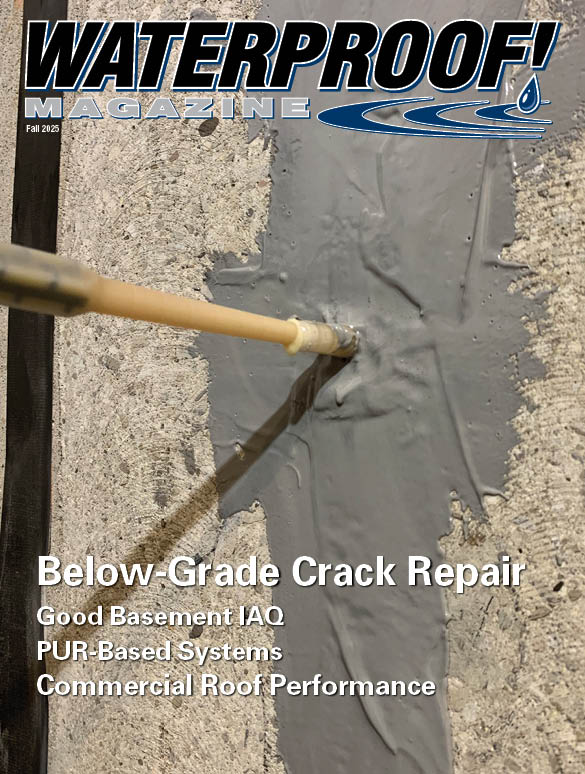

Fall 2025 Back Issue

Price range: $4.95 through $5.95

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

Restoration vs. Replacement: Maximizing Commercial Roof Performance

Below-Grade Crack Repair Solutions

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

Case Study: New York State Capitol Building

Description

Description

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

By Tom Stuewe, Senior Product Manager, Siplast

In today’s fast-paced commercial construction landscape, polyurea and polyurethane-based deck coating systems have become indispensable for their exceptional combination of durability, flexibility, and performance.

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

By Vanessa Salvia

Even if you don’t spend a lot of time in your basement, controlling the humidity and filtering that air before it moves to the upper levels of the home will improve your comfort and indoor air quality in the rest of the house.

Restoration vs. Replacement: Maximizing Commercial Roof Performance

By Vanessa Salvia

Commercial roofing presents challenges that set it apart from residential applications, such as being expansive surfaces that are almost flat. Proper maintenance programs can extend roof life well beyond design specifications and prevent the majority of warranty claims.

Below-Grade Crack Repair Solutions

By Vanessa Salvia

Modern techniques and materials are revolutionizing how contractors approach structural crack repair in basements, combining traditional injection methods with innovative carbon fiber reinforcement systems.

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

By Errol Bull, Technical Services Manager at Momentive Performance Materials

How do you know if waterproofing solutions will stand the test of time? One study, started in 1983, seeks to answer that question.

Case Study: New York State Capitol Building

A centerpiece in the heart of Albany, the New York State Capitol Building’s central courtyard required updates to its roofing and cladding.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |