by Jay Schmid

Today’s homeowners are demanding more useable living space, which increases expectations on their basements.

These spaces are increasingly being relied on for home offices, storage, and recreation, and nothing can ruin the enjoyment of that space more than a leaky foundation.

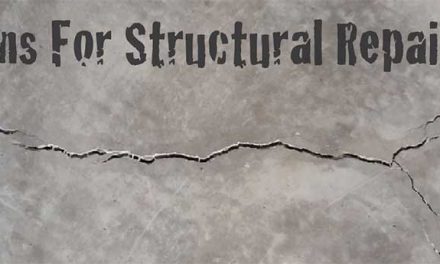

In spite of improved construction materials and techniques, concrete can still crack and cracks many times will leak. Fortunately there are a couple of simple-to-use systems that can provide economical and permanent repairs.

Low-pressure crack injection systems are becoming increasingly popular as the method of choice to repair leaky cracks in poured foundation walls. The days of digging, chipping and drilling are long gone as these easy-to-use injection systems allow for the repair and waterproofing of most foundation cracks from the inside using simple hand tools.

Today, both the epoxy and polyurethane resin are available in cartridge style systems that can be used with standard caulking guns or dual-cartridge dispensing tools. Both systems will effectively fill the crack while keeping water out.

The choice now becomes which system to use? Often a contractor will develop a preference for one injection system over, just like some prefer wood over fiberglass hammer handles. Many times the best tool for the job is the one that works best for you!

Epoxy Injection is traditionally used to weld cracked concrete back together to restore the structural integrity of the concrete wall. Epoxies are available in very low viscosities that make them ideal for injecting hairline cracks. Epoxy’s high-strength bonding ability makes them a clear choice for repairs such as concrete that cracked during backfilling.

Polyurethanes are available in one or two-part liquid resins that chemically react with available moisture and foam up and create a flexible seal inside the crack. They can even seal off the outside of the crack which can be preferable in porous or loose soil conditions. Polyurethane foam is ideal for filling wider cracks and cracks that may exhibit signs of settling or movement from changing seasons and soil pressures. Polyurethane also works great for filling in voids or sealing leaks around pipe penetrations.

Installation: Both systems can be installed in less than one hour and can be used conveniently from the inside of the basement. This eliminates the need for digging up the outside of the foundation which can be disruptive, time consuming and costly. Both resin systems are available in single 10-ounce caulking style cartridges or dual side-by-side cartridges and injected with low-pressure hand dispensing tools. Both systems are equally suited for typical foundation cracks but epoxy injection is best installed in dry cracks while polyurethane resin systems are moisture reactive and may actually require the crack to be pre-wet with a small amount of water in order to activate the full expansion of the resin.

Both systems are essentially installed the same way, with similar tools and techniques. First, surface mounted plastic injector ports are glued over the crack with a fast-setting epoxy paste at 10”-12” intervals. Additional epoxy paste is used to cover the crack between the ports. Once the epoxy surface seal has hardened, the resin of choice is slowly injected into the lowest port utilizing hand pressure equal to a firm handshake.

The resin will flow into the crack filling from the bottom up and then eventually appear at the next higher port. The flow of the injection resin is halted by releasing the pressure on the cartridge. Remove the nozzle from the lower port and cap the port. Move the cartridge up to the next higher port and resume injecting the resin again. Repeat this process until the entire crack is full and resin starts to flow out the top of the crack.

Tips: Seal up any part of the foundation crack visible above grade. Allow the surface paste epoxy to harden before starting the injection process. Attempting to inject too soon can cause the surface seal or ports to rupture or “blow-out”. Also applying too much pressure to the cartridge may encourage the tubes to leak.

Injecting urethane resins slowly will allow the resin time to begin reacting with the moisture and maximize the expanding action of the resin. After full cure of the injected resin system, the ports and epoxy surface seal may be removed for cosmetic reasons.

Always follow the manufacturers’ installation and safety instructions and finally, remember these are chemical adhesives that will stick to most everything—including you!

Mr. Schmid is general manager of Polygem, Inc., a manufacturer and epoxy and polyurethane crack injection systems.

Spring 2008 Back Issue

$4.95

Fixing a Broken Foundation

Sump Pumps Under the Stage

Built-Up Roofing: The Basics

AVAILABLE AS A PDF DOWNLOAD ONLY

Description

Description

Fixing a Broken Foundation

By Melissa Morton

Many waterproofers expand into the foundation repair business. From minor cracks to major underpinning work, here’s how to determine the severity of the problem, and the products and techniques used for repair.

Sump Pumps Under the Stage

By Clark Ricks

A significant portion of the new concert hall in Sonoma, Calif. sits below the water table. In order to keep the building dry—and the concert hall quiet—the building uses an innovative dewatering system.

Built-Up Roofing: The Basics

By Dan Calabrese

Considered the standard treatment for flat roofs, built up roofing is one of the oldest, most reliable, and overlooked methods.

Additional Info

Additional information

| Magazine Format | PDF Downloadable Magazine, Print Mailed Magazine |

|---|