Photos courtesy of Siplast

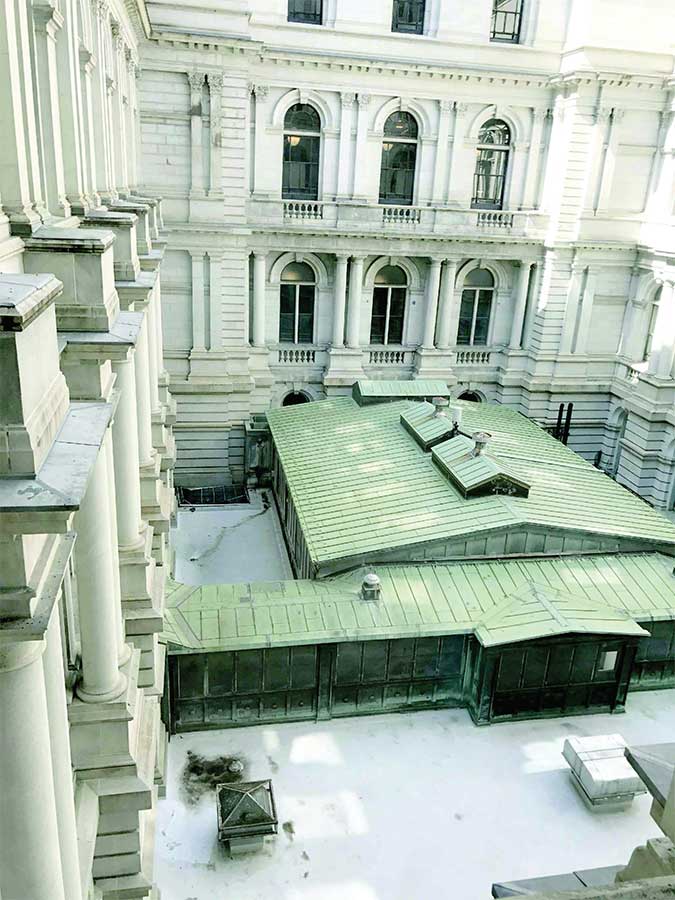

The New York State Capitol Building’s restored central courtyard.

centerpiece in the heart of Albany, the New York State Capitol Building remains a pillar of the community. Originally completed in 1873 after more than three decades of construction, the New York State Capitol Building is listed on the National Register of Historic Places. The building blends Renaissance Revival, Romanesque, and Victorian styles throughout the facade. Conceived by several prominent architects, including Thomas Fuller and Henry Hobson Richardson, the Capitol’s central courtyard features an extraordinary open-air passage and restaurant roofed and clad with eye-catching copper.

The Problem

By 2023, the New York State Capitol Building’s central courtyard required updates to its roofing and cladding. Initially crafted more than 120 years ago, the copper elements and membrane roofing were identified for replacement as part of a restoration effort. Bell & Spina Architects-Planners, PC, a Syracuse, New York-based building enclosure design firm, led the project, collaborating with fabricator and installer Greenwood Industries Inc.

Initially crafted more than 120 years ago, the copper elements and membrane roofing were identified for replacement as part of a restoration effort.

The project scope included replacing the existing 4,400-square-foot courtyard roof while maintaining historical accuracy and providing long-term performance. This process involved removing the previous flat roof areas down to the existing brick vaults and addressing areas of water infiltration.

The copper cladding and roofing featured intricate details, including flat seams, standing seams, ornate rosettes, egg-and-dart trim, and scrollwork, which required careful replication. Additionally, all materials, including six tons of copper, were transported through a single entrance without cranes to accommodate site constraints.

The Solution

A 21-month process, this comprehensive $2.6-million project demanded meticulous planning and precise execution. To achieve this remarkable renovation, Greenwood Industries Inc. tapped the roofing specialists at Siplast to honor the building’s rich history while implementing modern roofing solutions to safeguard its future.

Siplast’s Paraflex roof membrane system proved to be an excellent solution for this challenging project. The torch-applied and liquid-applied system provides exceptional waterproofing. A 1.5-inch layer of concrete was poured over the existing brick vaults, followed by a lightweight insulating concrete base layer installed by David Miorelli & Co.

The Siplast Paraflex system was then applied, creating a seamless, monolithic barrier to address the water leakage issues. Afterward, bluestone, granite, and concrete pavers — envisioned by the original architect in 1873 — were followed by the copper cladding, keeping the building’s historic design.

The restored courtyard seamlessly integrates the historical charm of the original design with expert copper craftsmanship and modern functionality. The new roof system replicates the original architect’s vision and helps ensure that the infrastructure remains protected, securing the Capitol Building’s legacy for generations.

FAST FACTS:

Project: New York State Capitol Building

Architecture: Bell & Spina Architects-Planners, PC

Fabricator and Installer: Greenwood Industries, Inc.

Solution Provider: Siplast

Solution: Paraflex Liquid Membrane

General Contractor: VMJR Companies

Subcontractor: Greenwood Industries, Inc.

Ownership: Office of General Services

Roofing Manufacturer: Siplast

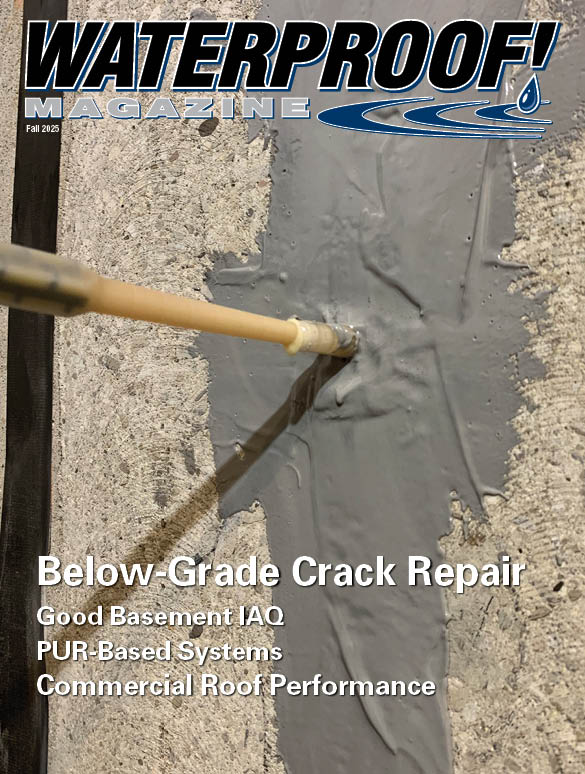

Fall 2025 Back Issue

Price range: $4.95 through $5.95

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

Restoration vs. Replacement: Maximizing Commercial Roof Performance

Below-Grade Crack Repair Solutions

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

Case Study: New York State Capitol Building

Description

Description

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

By Tom Stuewe, Senior Product Manager, Siplast

In today’s fast-paced commercial construction landscape, polyurea and polyurethane-based deck coating systems have become indispensable for their exceptional combination of durability, flexibility, and performance.

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

By Vanessa Salvia

Even if you don’t spend a lot of time in your basement, controlling the humidity and filtering that air before it moves to the upper levels of the home will improve your comfort and indoor air quality in the rest of the house.

Restoration vs. Replacement: Maximizing Commercial Roof Performance

By Vanessa Salvia

Commercial roofing presents challenges that set it apart from residential applications, such as being expansive surfaces that are almost flat. Proper maintenance programs can extend roof life well beyond design specifications and prevent the majority of warranty claims.

Below-Grade Crack Repair Solutions

By Vanessa Salvia

Modern techniques and materials are revolutionizing how contractors approach structural crack repair in basements, combining traditional injection methods with innovative carbon fiber reinforcement systems.

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

By Errol Bull, Technical Services Manager at Momentive Performance Materials

How do you know if waterproofing solutions will stand the test of time? One study, started in 1983, seeks to answer that question.

Case Study: New York State Capitol Building

A centerpiece in the heart of Albany, the New York State Capitol Building’s central courtyard required updates to its roofing and cladding.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |