by Vanessa Salvia

Photos courtesy of Kryton International

The SuperPier at the historic Pier 57 in New York underwent an extensive redevelopment. The application started with the team waterproofing the underwater vaults and pits by adding KIM to the concrete and treating all construction joints and penetrations with Krytonite Swelling Waterstop and Krystol Waterstop Treatment. These same products were then used for the floodproofing wall that wraps around the entire perimeter of the structure. Finally, to prevent water from infiltrating the entire exposed walkway that surrounded the pier, the team applied Kryton’s Krystol T1 and KIM solutions.

Recent extreme weather events such as heavy rain and flooding in Texas in March and in Dubai in April 2024, where they recorded their heaviest rainfall numbers in 75 years, among many other events, are challenging traditional waterproofing solutions. As these events become more frequent and intense, waterproofing professionals are on the front lines of climate adaptation, requiring new approaches, materials, and standards to protect structures for an increasingly unpredictable future.

The Sustainability Challenge

Climate change is forcing the waterproofing industry to rethink durability and longevity. According to Kevin Yuers, president of Kryton International, this shift has changed how the company communicates with customers.

“What has changed over the last few years is this attention to climate change and what to do about it,” says Yuers. “And one of the things that has changed at Kryton as a result is the way that we talk to people about our solutions.”

According to the World Green Building Council, the construction sector is responsible for 39% of global carbon emissions, with concrete production alone accounting for 8% of worldwide carbon dioxide emissions. Research shows that extending a building’s lifespan from 50 to 100 years can reduce its lifetime carbon footprint by up to 35%, demonstrating how durability directly impacts sustainability.

While Kryton originally focused on converting customers from membrane systems to crystalline waterproofing technology, their message has evolved to emphasize sustainability through durability.

“If you want a concrete structure, or any structure, to be more durable or to be more sustainable, the best way to be more sustainable is to be more durable — to just last longer,” Yuers explains.

Beyond Carbon Reduction

The concrete industry has seen numerous developments aimed at reducing carbon emissions, particularly by replacing portions of cement with alternatives like crushed limestone or magnesium. However, Yuers cautions that these substitutions may compromise durability.

“You can reduce a little bit of carbon dioxide now, but if the structure doesn’t last as long, if it’s not as durable, you haven’t gained anything,” Yuers points out. “You’re not actually being more green, because the structure you built was not sustainable, and that’s because it’s not durable.”

The expected lifespan of infrastructure has dramatically increased over time, requiring more robust waterproofing solutions.

“Back in the day, we would build bridges that you hoped would last 50 years,” notes Yuers. “But that’s crazy low today… We expect bridges and overpasses and tunnels and ports to last 100 years, 150 years, maybe even longer.”

He cites the massive Neom project in Saudi Arabia, which has a 200- to 250-year design life requirement, necessitating advanced technologies to extend lifespan.

For more than 120 years, a 2.2-mile-long seawall has encompassed Governors Island in New York. Over time, this impenetrable barrier started to wear down. To rehabilitate the wall, the New York City Economic Development Corp. chose Kryton’s waterproofing admixture, KIM.

The Threat of Extreme Weather

More frequent and severe weather events are occurring that put additional stress on waterproofing systems.

“We’re getting more and more extreme weather… it can be extremely hot, but it can also be extremely cold,” Yuers explains. “We’re dealing with extremes in the strength of the storms and the frequency of storms.”

Yuers emphasizes that these changing conditions require forward-thinking approaches: “If climate change continues as it is today, we can expect that the climate extremes will become even more extreme. Storms will be more frequent and maybe more powerful.”

He highlights freeze-thaw cycles as particularly damaging to concrete structures. “In some places where it would typically be below freezing in the winter, now your environment is a little warmer, and you get longer periods where there is freezing and thawing, and this cycle is extremely damaging to concrete.”

Many waterproofing professionals focus on keeping water out of habitable spaces, but Yuers points to another critical function of waterproofing: protecting structural reinforcement.

“Most of the early failures of concrete structures are because of corrosion of the steel,” Yuers says. “They get salt penetration, they get water, maybe they get cracks. You get corrosion of the steel, and then you get this death spiral where the corroding steel expands in space.”

This expansion then causes further cracking, accelerating water penetration and deterioration.

“Even making a concrete sea wall waterproof is important,” Yuers notes. “Most people might think it doesn’t make a difference if water gets through one direction or the other. Well, it does… because that sea wall has steel reinforcement, and once that starts to corrode, your sea wall lifespan is going to be short from there on in.”

At Governors Island, the team poured more than 2,000 cubic yards of KIM-treated concrete for the new and old sections of the seawall. That allowed them to eliminate the use of an external membrane installation and any of the coatings that go with it, as KIM is meant to go directly into the concrete mix to permanently waterproof the material.

Looking Beyond Today’s Conditions

For waterproofing professionals, considering future climate conditions is becoming essential when specifying systems.

“If you’re building something now and making a decision to waterproof it now, you’ve got to think about what the weather might be 10 years from now, which might be even more extreme than what you’re seeing now,” Yuers advises.

He acknowledges that the industry has varying perspectives on this long-term approach. “Some builders do think long-term and some don’t,” he says. “If you’re building a condo tower, you’re going to build it and you’re going to sell it. But if you’re building some infrastructure, like a bridge or a dam, you expect that to last for generations to come.”

Solutions for a Changing Climate

Kryton offers products specifically designed to enhance durability in the face of climate challenges. Their flagship product, KIM (Krystol Internal Membrane), was the original crystalline waterproofing admixture, which grows crystals to block pores and micro-cracks in concrete.

Their Hard-Cem product is another admixture designed to increase concrete durability, especially for industrial slabs. “It can double the life of a concrete slab just by adding abrasion resistance,” says Yuers.

He points out the economic and environmental benefits: “You’re really adding perhaps 10% to the cost of the concrete, but you’re adding perhaps 100% to the life of the concrete, so it’s a really good value.”

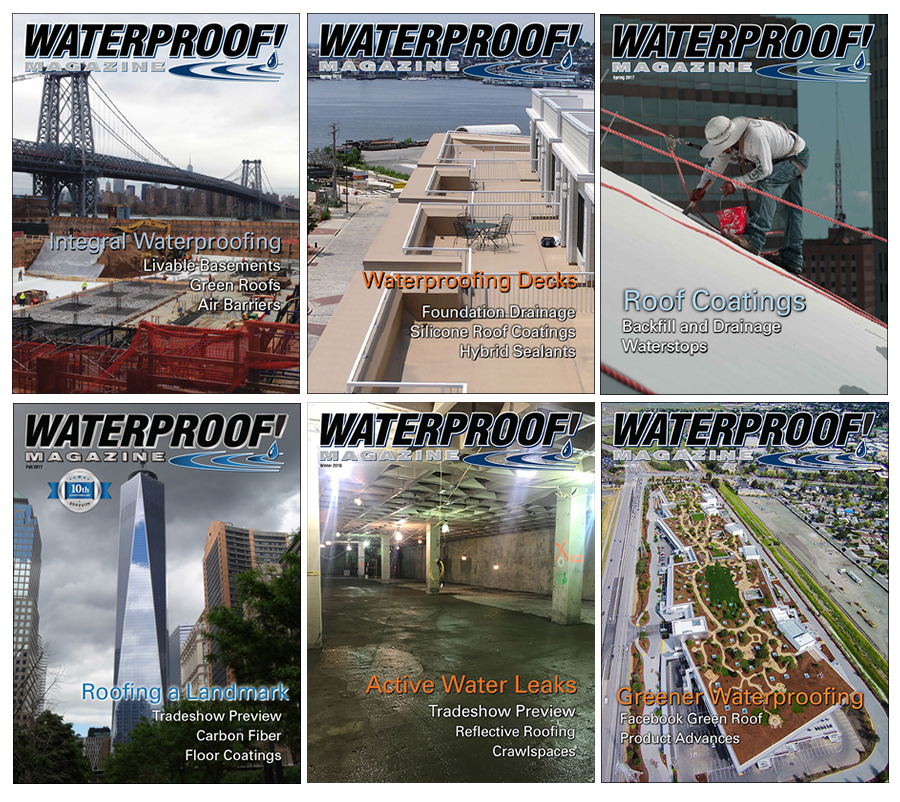

Magazine Subscription

Price range: $20.00 through $60.00

1 Year Subscription $20

2 Years Subscription $35

5 Years Subscription $50 (Best Deal!)

*Shipped International orders are an additional $10 per year

Description

Description

WATERPROOF!, a full-color quarterly magazine, promises to become the information resource for all types of waterproofers.

Our readers include residential and commercial waterproofers, foundation contractors, and thousands of large roofing contractors. Our readership also includes architects, engineers, and specifiers who are looking for product information.

The stories and features in the magazine are geared toward hardworking contractors and small business owners who need relevant information, written in plain English, applicable to his business and jobsite.

We cover all aspects of the waterproofing industry—residential and commercial waterproofing, spray-on and sheet good. So whether your business or product is focused on below-grade work, roofing, or structural repair and foundation remediation, you’ll find WATERPROOF! to be the best place to turn for information. WATERPROOF! is mailed to more than 10,000 interested readers throughout the U.S. every quarter.

With eye-catching graphics, vivid photographs, highly targeted audience and some of the best writing around, this is one magazine you can’t afford to miss.

SUBSCRIBE TODAYPlease Note: Your subscription to WATERPROOF! Magazine will begin with the next issue. However, you will receive a complimentary PDF copy of the current issue at checkout. If you would like to receivalle a copy of other previous issues, please add them to your cart as “Back Issues”. |

Additional Info

Additional information

| Duration | 1 Year, 2 Years, 5 Years |

|---|---|

| Subscription Format | Digital Download Magazine, Print Mailed Magazine (USA, Print Mailed Magazine (International) |