By Vanessa Salvia

Photos and illustrations courtesy of Soprema

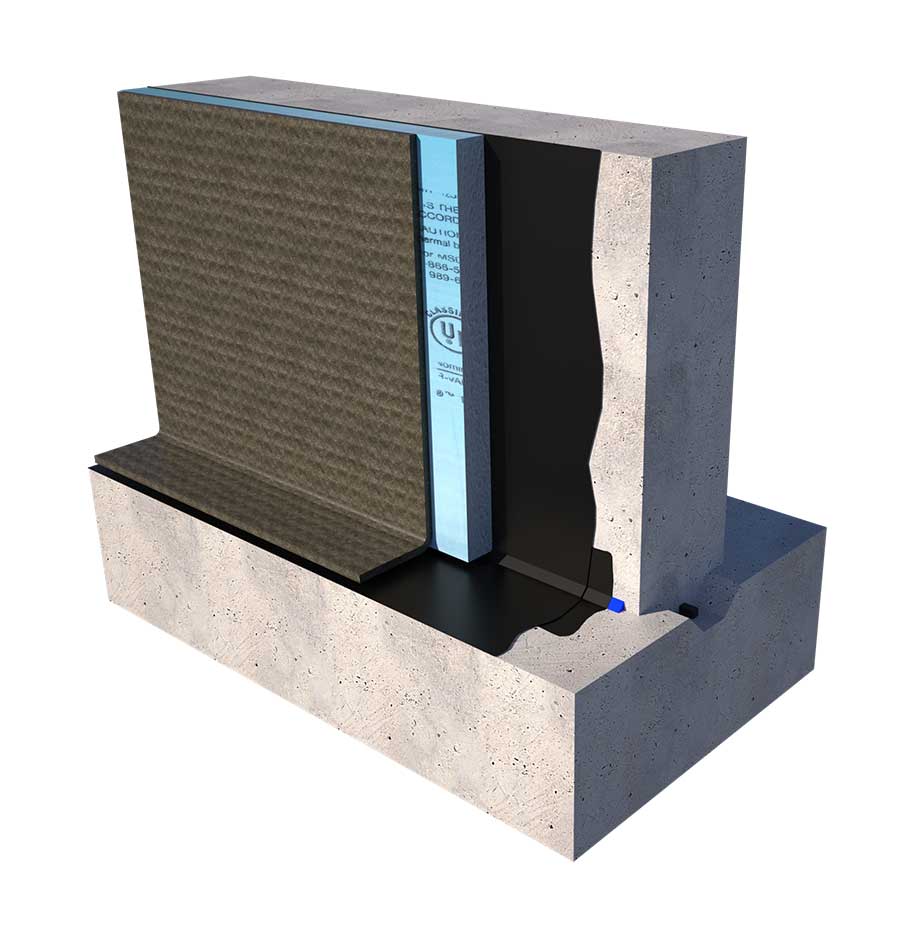

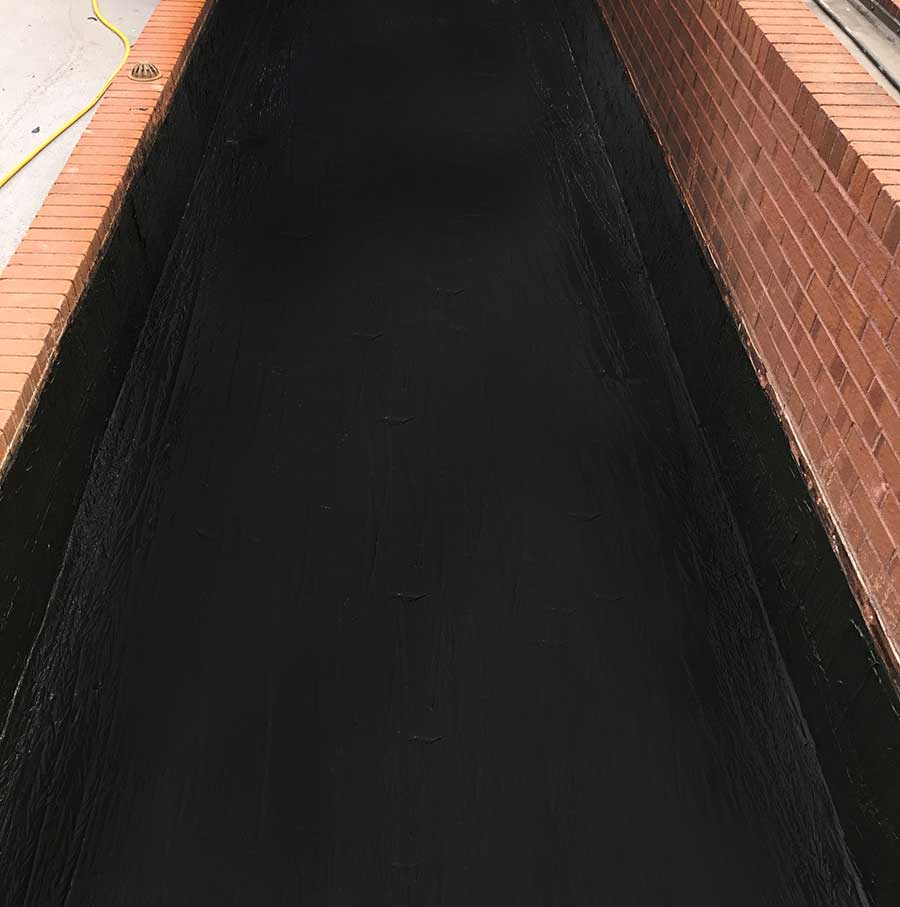

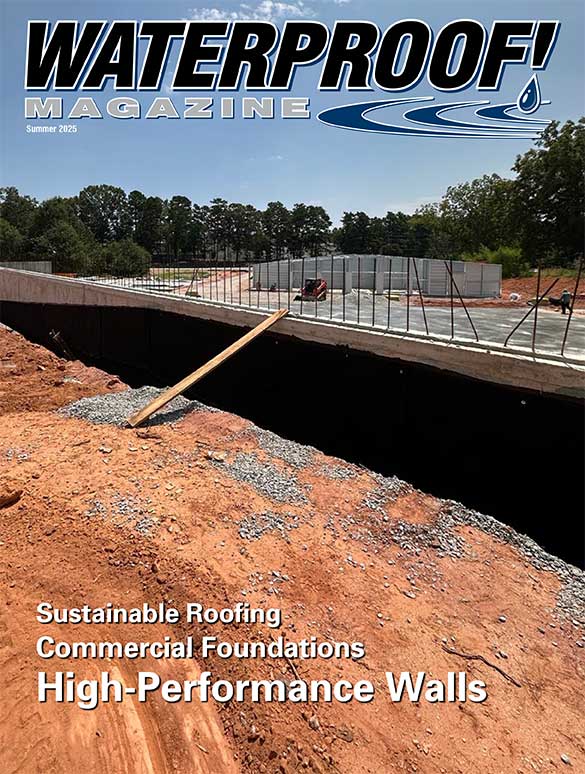

Soprema’s spray-applied Colphene LM Barr.

In an industry where waterproofing technology continues to evolve, liquid waterproofing systems have emerged as innovative solutions for wall applications. These high-performance products offer significant advantages over traditional membrane systems, with companies like Soprema developing specialized formulations that address common industry challenges.

Preventing Shrinkage in Below-Grade Applications

One of the most critical challenges in below-grade waterproofing is preventing shrinkage as products cure.

“When you take a look at below-grade waterproofing, one of the biggest issues is that as the film cures, whether it’s water or solvents, the coating will shrink,” explains Izzy Gutman, director of product management at Soprema. “For a waterproofing product, you don’t want it to shrink, because then you’re going to expose the surface, and if you expose that surface, you’re able to absorb any moisture that’s coming from the outside trying to get in.”

Modern high-solids liquid waterproofing addresses this concern by minimizing shrinkage. Shrinkage refers to the reduction in volume or dimension that occurs as a liquid waterproofing material cures and dries. This happens primarily through evaporation, when solvents or water in the formula evaporate during curing, or through a chemical reaction, as components react and cross-link to form a solid membrane.

High-solids formulations minimize shrinkage because they contain very little solvent or water that can evaporate. This means the wet volume when applied remains very close to the final cured volume, ensuring continuous coverage of the substrate.

Soprema’s Colphene LM Barr contains 98% solids, which virtually eliminates shrinkage issues. “With our product being at 98% solids, there’s very, very little shrinkage, if at all any, which means it won’t expose that surface to any moisture or other exposure,” Gutman notes.

Application Versatility

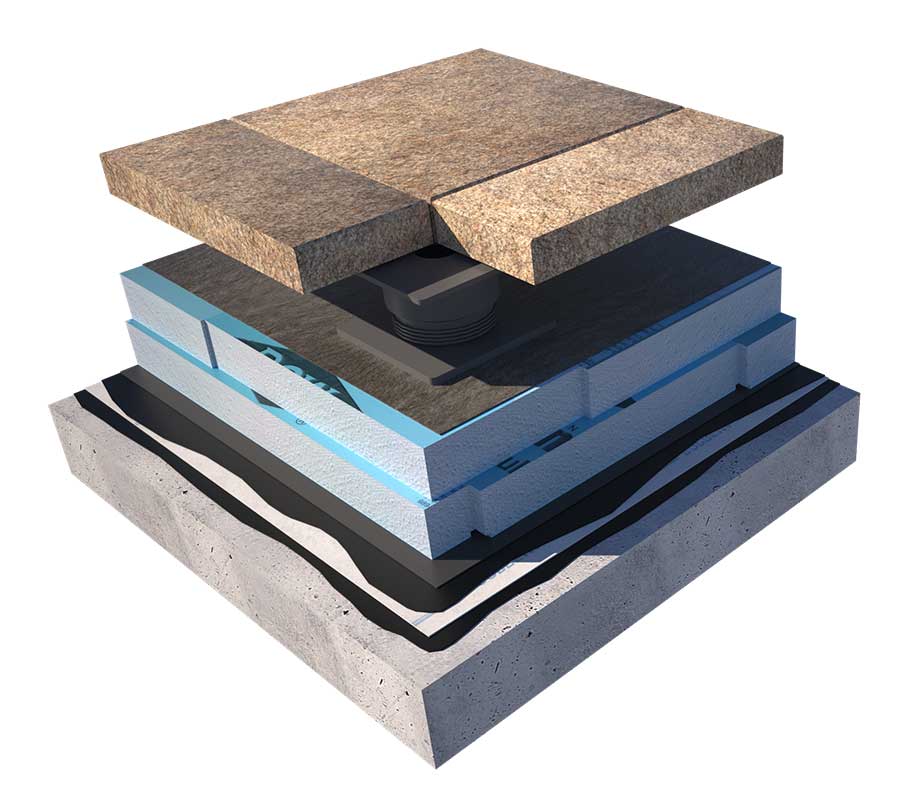

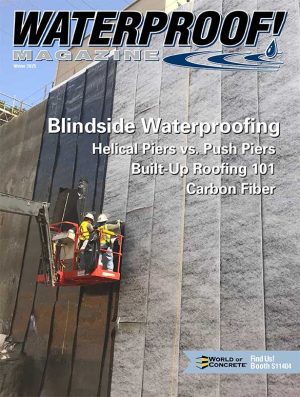

Today’s liquid waterproofing systems offer multiple application methods to suit various project requirements. Traditional squeegee applications remain common for smaller projects, while spray technologies have revolutionized larger applications.

“Our spray grade is a more convenient way to apply a product on the wall if you have the equipment to do that,” explains Fred Gage, product manager at Soprema. “It’s one of the advantages of having that product, because a number of our competitors’ products are not sprayable, so you have to spend more labor and time to actually apply the product.”

The industry has seen significant advances in product performance specifications. Elongation is the ability of a cured waterproofing membrane to stretch without breaking or tearing. It’s typically measured as a percentage. 100% elongation means the material can stretch to twice its original length. High elongation is important because structures naturally shift, settle, and expand/contract with temperature changes. Also, daily and seasonal temperature changes cause materials to expand and contract.

A waterproofing membrane with high elongation properties can accommodate these movements without tearing or failing. This is particularly important at joints, corners, and transitions between different building materials, where movement is often concentrated.

High-quality liquid waterproofing systems now commonly feature elongation properties of 300% or more, with Colphene LM Barr offering 378% elongation. Rapid curing technologies have also become standard, with many products achieving tack-free times of under 60 minutes and becoming rain-ready shortly after application.

Low shrinkage and high elongation create a waterproofing system that maintains continuous contact with the substrate and can adapt to building movement without compromising its water-resistant properties.

Environmental Considerations

Environmental responsibility has become a significant driver in waterproofing technology development. The industry has moved decisively away from solvent-based formulations toward water-based and reactive systems with minimal VOC emissions.

Many manufacturers now utilize silane-terminated polyether (STPE) technology, which provides natural water repellency. As Gutman explains about Colphene LM Barr, “It’s a natural water repellent product, which is manufactured using the silane terminated polyether, which is highly attuned with the surface. The components that we make this product out of are naturally moisture resistant.”

Application Best Practices

Proper surface preparation remains essential for optimal waterproofing performance regardless of the product used. Industry standards typically require substrates to be clean, dry, and free from irregularities or foreign material.

For concrete applications with products like Colphene LM Barr, surface profiles should be CSP-3 to CSP-4, and all CMUs must have flush joints with no voids. Application thicknesses vary by system, with single-coat applications typically ranging from 30 to 120 mils. When additional reinforcement is needed, systems often incorporate reinforcing fabrics between coats, such as Soprema’s Polyfleece, which is a proprietary non-woven polyester reinforcement used in various waterproofing and flashing applications.

Performance in Extreme Conditions

Modern liquid waterproofing systems undergo rigorous testing to ensure performance across diverse environmental conditions. Industry-standard tests such as ASTM C836 and ASTM C1305 evaluate low-temperature crack-bridging capabilities, which high-performance products like Colphene LM Barr pass successfully.

The development of moisture-cure technologies has significantly improved product performance in temperature extremes, with many systems maintaining flexibility and integrity across wide temperature ranges.

Market Trends

The liquid waterproofing industry is experiencing significant growth, with the market expanding at a compound rate of approximately 5.2%, said Gutman. This growth is driven by increasing construction activity, renovation of aging infrastructure, and growing awareness of building envelope performance.

There is also an increasing emphasis on sustainable waterproofing solutions, with development activities centered on creating bio-based and recyclable materials. This aligns with global efforts to reduce environmental impact and promote eco-friendly construction practices.

The liquid-applied membrane segment accounted for the largest market share in 2024, driven by its flexibility, ease of application, and superior adaptability to complex building structures — a trend that indicates a growing preference for liquid waterproofing solutions in various construction applications.

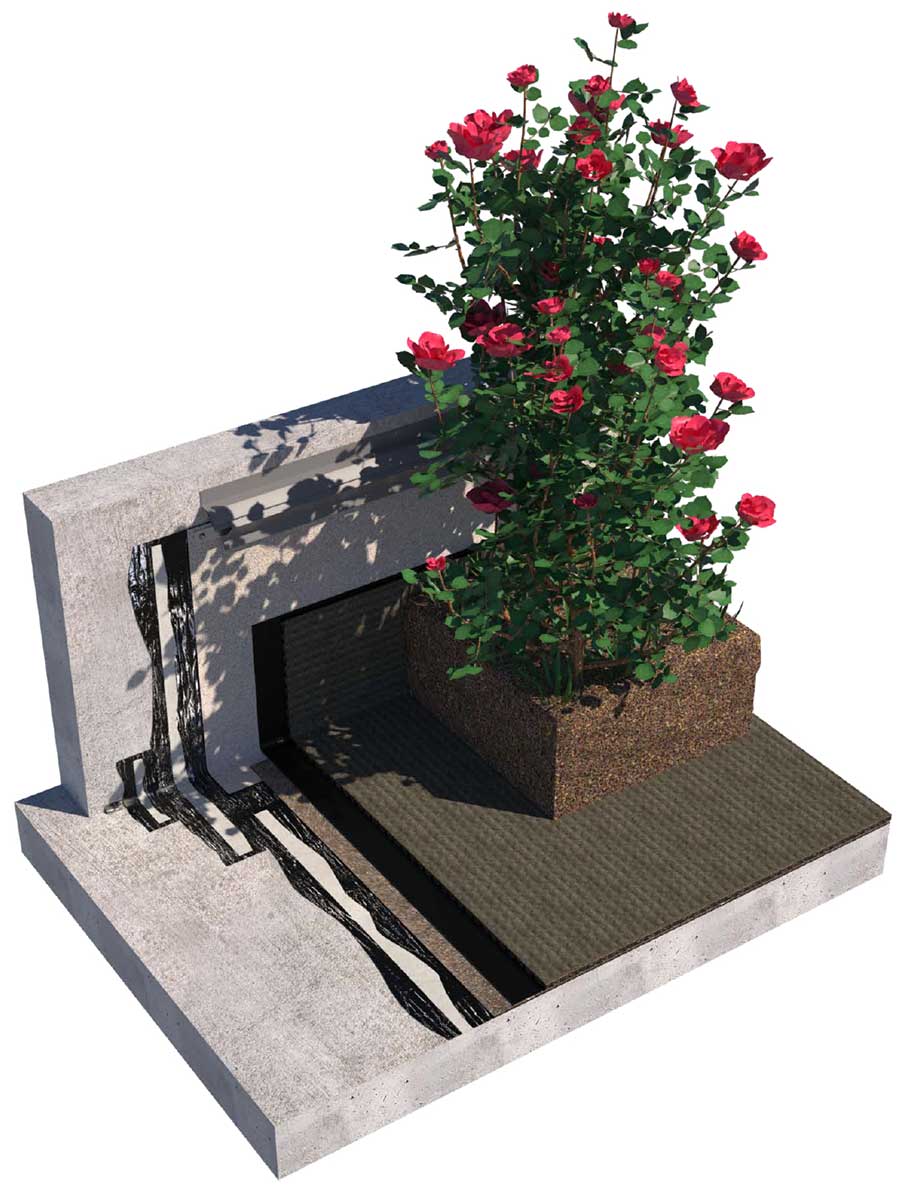

Diverse Application Areas

Liquid waterproofing systems are beneficial for numerous building types including:

- High-Rise Buildings – Liquid waterproofing ensures a continuous barrier against wind-driven rain and water infiltration, especially in buildings with complex facades.

- Restoration & Renovation Projects – Older buildings with irregular surfaces or historical structures benefit from liquid-applied waterproofing, which can adapt to unique architectural details.

- Hospitals & Healthcare Facilities – These require high-performance waterproofing to maintain sterile environments and prevent mold growth in critical areas.

- Educational Institutions – Schools and universities often use liquid waterproofing for long-term durability and protection against weathering.

- Industrial & Commercial Buildings – Warehouses, manufacturing plants, and retail centers need liquid-applied waterproofing for ease of maintenance and robust moisture control.

- Multi-Family Residential Buildings – Apartments and condominiums benefit from liquid waterproofing due to its ability to seal joints, cracks, and penetrations effectively.

- Government & Military Facilities – These require high-performance, long-lasting waterproofing solutions for security and resilience in harsh environments.

- Green & Sustainable Buildings – Liquid waterproofing integrates well with energy-efficient wall assemblies and contributes to LEED certification goals.

When properly installed, high-performance liquid waterproofing systems like Colphene LM Barr can be expected to last the life of the building, providing long-term protection against water intrusion while minimizing maintenance requirements.

With their innovative formulations, ease of application, and environmental benefits, today’s high-performance liquid waterproofing systems represent significant advancements in building envelope protection technology.

Summer 2025 Back Issue

Price range: $4.95 through $5.95

High-Performance Liquid Waterproofing for Walls

Sustainable Roofing

Waterproofing Commercial Foundations

Description

Description

High-Performance Liquid Waterproofing for Walls

By Vanessa Salvia

In an industry where waterproofing technology continues to evolve, liquid waterproofing systems have emerged as innovative solutions for wall applications.

Sustainable Roofing

By Richard C. Hayden, GRP ASLA-Emeritus

The roof is one of the most important components in any building. The roof provides the primary defense against the elements of sun, snow, and rain.

Waterproofing Commercial Foundations

By Wes Settlemyre

The foundation is arguably the most critical component of a commercial building. However, one of the greatest threats to a foundation is water infiltration.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |