By Vanessa Salvia

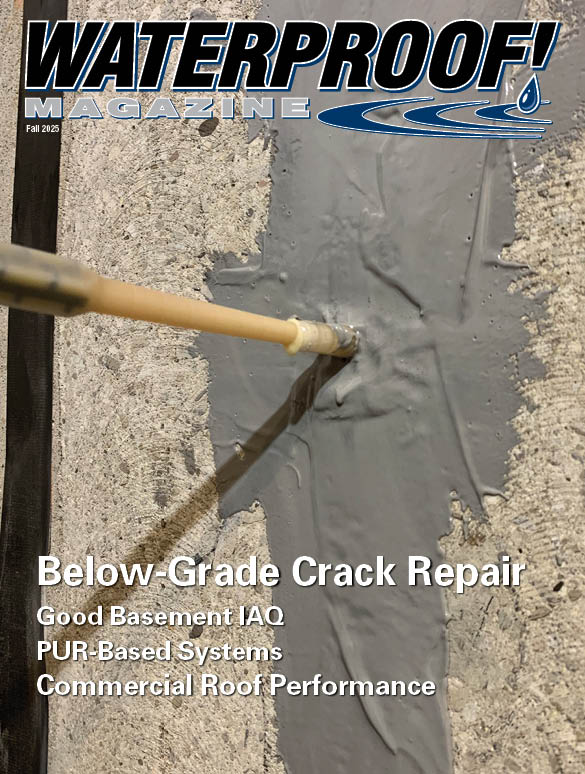

Photos courtesy of Emecole

This repair included Emecole’s Titan Crack and Mortar Filler which is used to fill in any mortar joints or divots so the strap will lay perfectly flat. It was then followed by Emecole’s Titan Saturant, then strap, then Saturant again.

Modern techniques and materials are revolutionizing how contractors approach structural crack repair in basements, combining traditional injection methods with innovative carbon fiber reinforcement systems.

The fundamental challenge of stopping water infiltration while addressing structural integrity remains the same, and the new tools and methods available today provide effective and efficient results.

Understanding the Repair Challenge

Below-grade crack repair presents unique challenges. Marge Kaminski, sales manager for Emecole Metro, explains that there are essentially two different approaches for interior structural repair: one for block walls and another for poured walls. Carbon fiber fabric is typically used to address bowing in block walls, while epoxy injection is the go-to solution for issues in poured concrete walls.

The key to successful crack repair lies in understanding that simply sealing a crack isn’t enough. While injection products or sealants will stop water flow and potentially block gases like radon, they don’t provide the structural properties needed to prevent crack reopening.

“There are a variety of reasons why cracks form in concrete,” notes Paul Trzcinko, project manager for AGT Products, which manufactures Rhino Carbon Fiber products. “It could be hydrostatic pressure from the soil, freeze-thaw cycles, moisture, settlement, or improper pouring of the concrete.”

The Modern Repair Process

Today’s best practices follow a systematic four-step approach that addresses both immediate water intrusion and long-term structural integrity: Preparation involves cleaning the surface of debris, dust, and imperfections. For carbon fiber fabric applications, the surface should be ground to CSP 3 or “orange peel texture” to ensure optimal epoxy bonding.

Sealing varies based on crack width. Hairline cracks can be sealed directly with high-strength anchoring epoxy paste without injection. Cracks measuring 1/16 to 1/8 inches wide require injection ports installed every 6 to 12 inches prior to injection. For larger cracks exceeding 1/8 inches, instant-set concrete repair mortar fills the gap before proceeding.

Injection utilizes either structural epoxy injection resin for dry cracks or polyurethane injection expanding foam for wet or dry applications. The choice depends on specific site conditions and crack characteristics.

Reinforcement completes the repair by strengthening the area with carbon fiber products, ensuring long-term structural integrity.

Prior to CFRP application, prep the wall or the slab by grinding away any imperfections and ensuring that the surface area is clean and sound. Photos courtesy of Rhino Carbon Fiber

Surface Seal Technology

One recent innovation comes from Emecole with their Metro 701 Premium Surface Seal, released approximately six months ago. It is a low odor, rapid-curing sealer for more efficient sealing of cracks prior to injection. Injection may begin within 20 to 25 minutes after application to the wall. This allows a contractor to potentially add to their bottom line by being able to schedule more repairs in a day. It is formulated to be thicker than traditional surface seals to better adhere to vertical surfaces.

For injectable cracks, the choice is between epoxy or polyurethane depending on your application.

The product adds to their line of surface seals, including the 322 which peels cleanly off walls after injection, allowing for repairs that are far less noticeable to homeowners. “This gives contractors a way to offer customers something they really want, which is the ability to peel that surface seal right off the wall when the job’s done,” Kaminski says. “Nobody wants to look at repair materials on their basement wall forever.”

The 701 seals the front of cracks effectively, preventing injected material from leaking out and resulting in less waste and mess. The fast cure time of 35 to 45 minutes allows injections to begin quickly, enabling contractors to complete more jobs per day.

Reinforce with either carbon fiber fabric for walls or the dumbbell carbon concrete crack lock stitches for slabs.

The Carbon Fiber Standard

Carbon fiber reinforcement has emerged as a leading solution for crack strengthening. When mixed with compatible epoxy to form a CFRP (Carbon Fiber Reinforced Polymer) system, carbon fiber cures to 10 times the strength of steel while maintaining a thin profile that doesn’t consume valuable basement space.

For wall applications, contractors can choose from various carbon fiber fabric options based on three key attributes: weave orientation (unidirectional horizontal, unidirectional vertical, or bidirectional), weight (200 GSM to 710 GSM), and width (5.5 inches to 24 inches). CFRP laminate, available in 328-foot rolls, represents the strongest pre-saturated option available.

For slab repairs, dumbbell-shaped concrete crack lock stitches provide targeted reinforcement. These carbon fiber components are installed by drilling two holes, sawing a line across the crack, applying epoxy, dropping the stitch in place, and sealing — a process that’s both effective and relatively straightforward.

Identifying Structural Issues

Rhino Carbon Fiber promotes a “prep, inject, and reinforce” approach.

“You want to prep the wall or slab first by grinding away any imperfections manually or with machinery to de-dust it,” explains Trzcinko. “You want to make sure that surface area is clean, sound, and in a proper preparation state before you start doing any other work.”

If the crack isn’t wide enough to inject, it is sealed. “To seal it, we would use our high-strength anchoring epoxy paste, and that is simply a paste that is concrete gray in color. It’s used to seal holes, pits, and cracks.” For injectable cracks, the choice is between epoxy or polyurethane depending on your application. Polyurethane is good for any wet or dry crack, while the epoxy resin is only for dry cracks.

Both products only prevent further water or gas entry, but you still need to reinforce. “You use either carbon fiber fabric for walls or concrete crack lock stitches for slabs,” says Trzcinko. Prebuilt wall repair kits are available.

This basement repair project used unidirectional, vertical carbon fiber for reinforcement. Photo courtesy of Rhino Carbon Fiber

The Bottom Line

Comprehensive crack repair requires addressing both water infiltration and structural integrity. “You always want to fix the leak or crack first, then you strengthen the area,” says Trzcinko. “Once that’s all said and done, you can paint or coat over top of it. For slabs, you can use most floor coatings because the crack lock stitches are virtually invisible after installation.”

Fall 2025 Back Issue

Price range: $4.95 through $5.95

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

Restoration vs. Replacement: Maximizing Commercial Roof Performance

Below-Grade Crack Repair Solutions

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

Case Study: New York State Capitol Building

Description

Description

PUR-Based Systems: A High-Performance Concrete Protection and Traffic Coating Solution

By Tom Stuewe, Senior Product Manager, Siplast

In today’s fast-paced commercial construction landscape, polyurea and polyurethane-based deck coating systems have become indispensable for their exceptional combination of durability, flexibility, and performance.

Breathing Easy With Good Indoor Air Quality, Starting with the Basement

By Vanessa Salvia

Even if you don’t spend a lot of time in your basement, controlling the humidity and filtering that air before it moves to the upper levels of the home will improve your comfort and indoor air quality in the rest of the house.

Restoration vs. Replacement: Maximizing Commercial Roof Performance

By Vanessa Salvia

Commercial roofing presents challenges that set it apart from residential applications, such as being expansive surfaces that are almost flat. Proper maintenance programs can extend roof life well beyond design specifications and prevent the majority of warranty claims.

Below-Grade Crack Repair Solutions

By Vanessa Salvia

Modern techniques and materials are revolutionizing how contractors approach structural crack repair in basements, combining traditional injection methods with innovative carbon fiber reinforcement systems.

Four Decades of Proof: Why Silicone Coatings and Sealants Stand the Test of Time

By Errol Bull, Technical Services Manager at Momentive Performance Materials

How do you know if waterproofing solutions will stand the test of time? One study, started in 1983, seeks to answer that question.

Case Study: New York State Capitol Building

A centerpiece in the heart of Albany, the New York State Capitol Building’s central courtyard required updates to its roofing and cladding.

Additional Info

Additional information

| Weight | N/A |

|---|---|

| Magazine Format | Digital Download Magazine, Print Mailed Magazine |